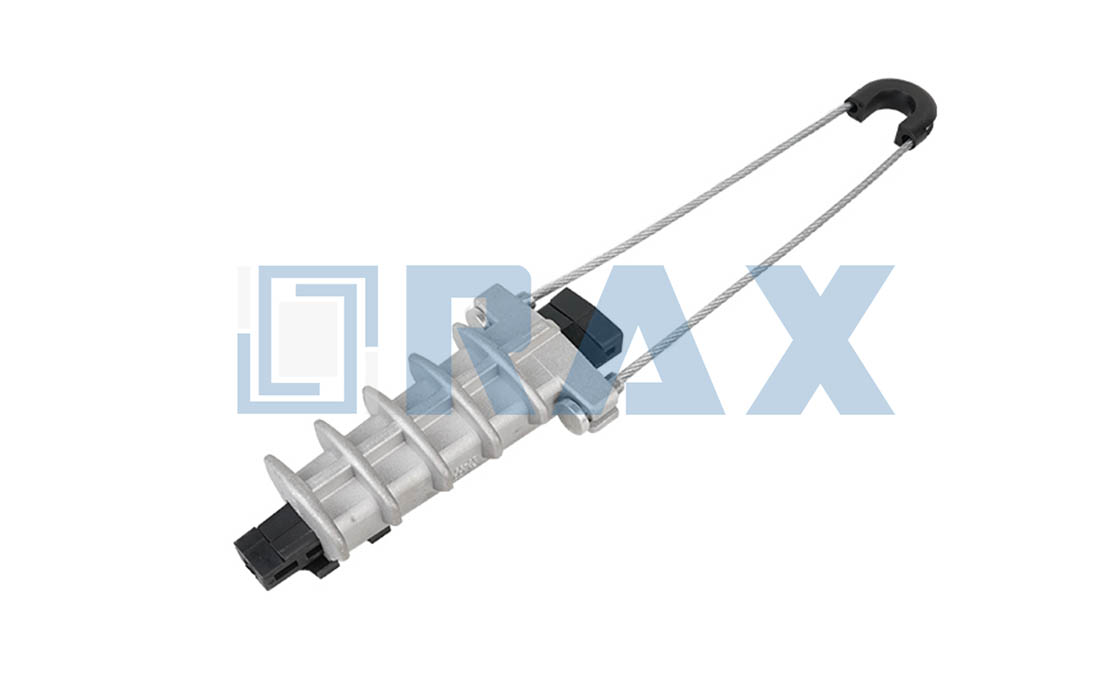

Suspension clamps are hardware components that suspend and secure cables—such as power conductors or fiber optic lines—from poles or towers in overhead transmission and distribution systems. They manage static and dynamic stresses on conductors, reducing movement from wind or environmental factors while providing stable support. Available types include angled, corona-free, standard, trunnion, and helical models, each suited to specific installation requirements in power and utility networks.

Construction typically involves aluminum alloy or ductile iron bodies offering strength and corrosion resistance. Components include galvanized steel hardware, stainless steel fasteners, or Ultraviolet (UV)-resistant polymers like glass-filled nylon, enhancing durability against moisture, chemical exposure, and adverse weather. Continuous operating temperatures reach up to 125°C in standard models, with some insulating variants extending to 160°F.

Key features include factory-installed fasteners eliminating loose parts during field installation, compatibility with standard attachment hardware, and designs facilitating labor savings. Some models incorporate preloaded nails or self-adjusting wedges for quick setup, while others reduce noise by minimizing vibrations from cable expansion and contraction. Impact resistance allows certain clamps to endure low temperatures and mechanical stresses without degradation.

Applications span Extra High Voltage (EHV) systems, telecommunications infrastructure, and aerial power lines, accommodating conductors such as All Aluminum Conductor (AAC), Aluminum Conductor Steel Reinforced (ACSR), or All-Dielectric Self-Supporting (ADSS) cables. Clamping ranges accommodate diameters from 0.16 to over 2 inches, with load capacities reaching 18,000 pounds for ductile iron models and bolt torque requirements of 11 to 40 ft-lbs depending on size.

Your Premier Suspension Clamp Manufacturer

RaxPower is a leading manufacturer of suspension clamps in China, with over 21 years of expertise since its establishment in 2003 in Hebei Province. Our suspension clamps are engineered to provide reliable and secure support for overhead transmission and distribution lines, ensuring maximum efficiency and safety through unmatched quality and durability. Crafted from premium materials like galvanized steel and aluminum alloy, they feature corrosion-resistant coatings to withstand harsh weather conditions and reduce long-term maintenance costs.

Key components and features include:

- Body: Forged from high-strength aluminum alloy using advanced hot forging technology for superior strength and precise sizing.

- Keeper: Designed to securely connect conductors, minimizing stress and abrasion.

- Straps and fittings: Made from coated zinc materials for effective load transfer and corrosion resistance.

With 17,000 square meters of production workshops equipped with automatic machines and rigorous quality control—including multi-stage testing, load tests, and hot-dip galvanizing per ISO 1461—we guarantee that every suspension clamp meets the highest industry standards and has passed SGS certifications. Easy to install and maintain, our clamps are ideal for various applications, including ADSS, ABC, and OPGW cables, offering tailored solutions for the power industry.

Committed to customer satisfaction, RaxPower delivers only the best products and services. Contact us today for more information and experience the reliability and excellence of our suspension clamps in your power systems.

| Type | Model | Conductor Range (inches) | Clamping Range (inches) | Load Capacity (lbs) | Bolt Torque (ft-lbs) | Materials | Continuous Operating Temperature (°C) |

|---|---|---|---|---|---|---|---|

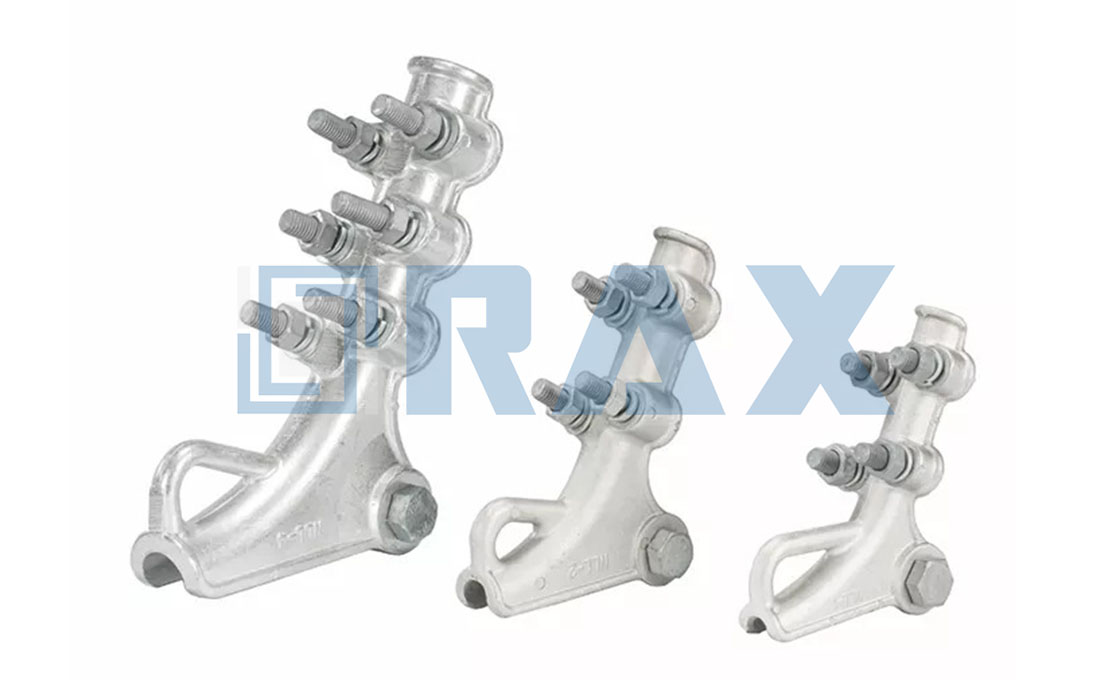

| Standard Suspension Clamp | ALS-47 to ALS-236 | 0.200 – 2.360 | 0.16 – 2.04 | 16,000 – 18,000 | 11 – 40 | Aluminum alloy body with galvanized steel hardware and stainless steel fasteners | 125 |

| Helical Suspension Clamp | HSC-0556-N to HSC-1829-EHVN | 0.543 – 1.882 | 0.543 – 1.882 | 16,000 – 18,000 | N/A | Aluminum alloy | 125 |

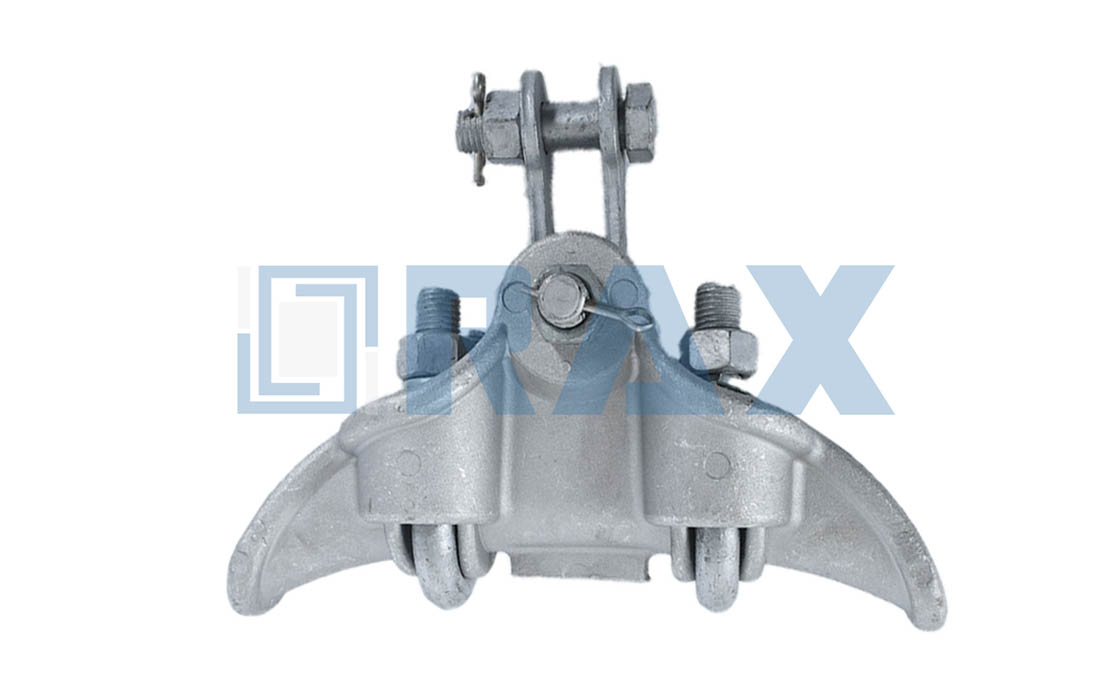

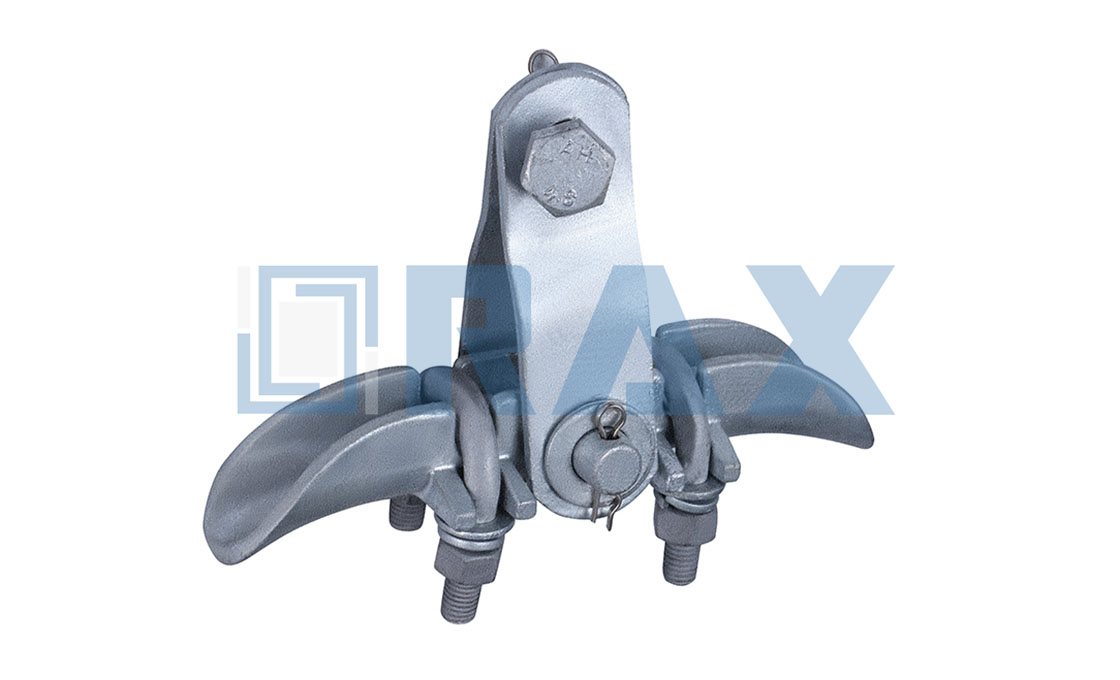

| Angled Suspension Clamp | Various | 0.23 – 0.75 | 0.16 – 2.04 | 16,000 – 18,000 | 11 – 40 | Aluminum alloy or ductile iron with galvanized steel hardware | 125 |

| Corona Free Suspension Clamp | Various | 0.23 – 0.75 | 0.16 – 2.04 | 16,000 – 18,000 | 11 – 40 | Aluminum alloy with corona-resistant coatings | 125 |

| Trunnion Suspension Clamp | Various | 0.25 – 1.50 | 0.16 – 2.04 | 16,000 – 18,000 | 11 – 40 | Ductile iron or aluminum alloy with galvanized steel hardware | 125 |

Frequently Asked Questions (FAQS)

What is a suspension clamp?

Suspension clamps are used in overhead transmission lines to suspend or hang cables, providing protection to conductors by reducing swinging caused by strong winds and storms. They ensure a secure connection and mechanical support for power and utility applications.

What types of suspension clamps are available?

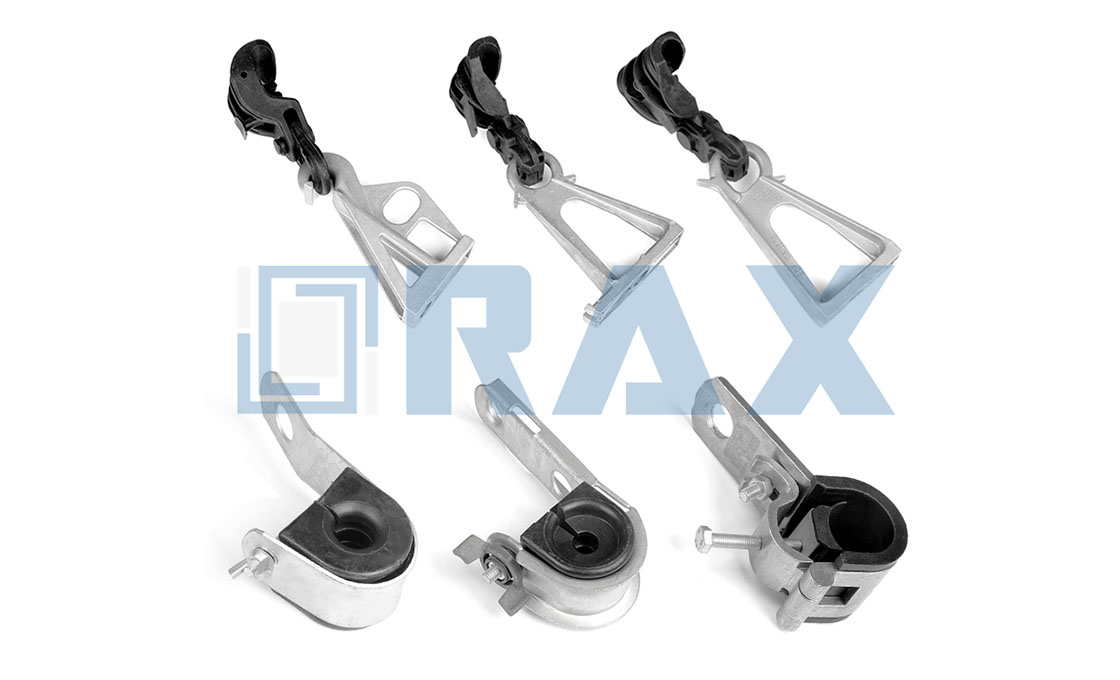

RaxPower offers a variety of suspension clamps, including angled, corona free, standard, trunnion, vertical bundle assembly, and helical types. These are designed for different conductors such as AAC, ACSR, ACSS, and for specific cables like ADSS, ABC, and OPGW to meet diverse needs from power transmission to telecommunications.

What materials are suspension clamps made from?

Suspension clamps are typically constructed from galvanized steel, stainless steel, aluminum alloy, or combinations such as aluminum alloy bodies with galvanized steel hardware. Some models feature UV-resistant materials like glass-filled nylon for enhanced durability. At RaxPower, we employ hot-dip galvanization with mean coating thickness over 85 microns to ensure corrosion resistance.

What are the key features of suspension clamps?

Key features include corrosion resistance, ease of installation with no loose parts, durability in harsh weather conditions, and compatibility with standard attachment hardware. They are designed to withstand extreme temperatures and provide reliable performance with minimal maintenance.

How do I select the right suspension clamp for my application?

Consider factors such as the cable type and diameter, conductor range, required load capacity, environmental conditions, and compliance with relevant standards. Ensure the clamp matches the conductor specifications, such as ACSR or aluminum, and check for features like adjustable gripping and mechanical strength.

What standards do suspension clamps comply with?

Suspension clamps from RaxPower comply with various industry standards, such as NFC or NF standards, and are tested for tensile strength, thermal cycling, aging, and corrosion resistance to ensure they meet high performance and safety requirements.

What is the typical load capacity and cable range for suspension clamps?

Load capacities and cable ranges vary by model, with some clamps designed for conductors from 0.16 inches to over 2 inches in diameter, and load capacities up to 18k lbs or higher. Specific models support different conductor types like ACSR or aluminum, with clamping ranges tailored to application needs.

What is your capacity for handling bulk orders and ensuring on-time delivery?

At RaxPower, with 17,000 square meters of production workshops and automated processes, we can handle bulk orders efficiently. Our use of automatic machines and semi-automatic molds ensures uniform quality and on-time delivery, supported by over 21 years of experience in manufacturing and exporting.

How do your suspension clamps for fiber optic cables protect against environmental factors?

Specialized suspension clamps for fiber optics, like ADSS types, are made with materials such as TPR rubber and galvanized steel, offering high tensile strength and corrosion resistance. At RaxPower, our ADSS/OPGW accessories feature self-adjusting wedges and undergo rigorous testing for thermal cycling, aging, and load capacity to ensure durability and reliable performance in all conditions.

Get A Quick Quotation Today