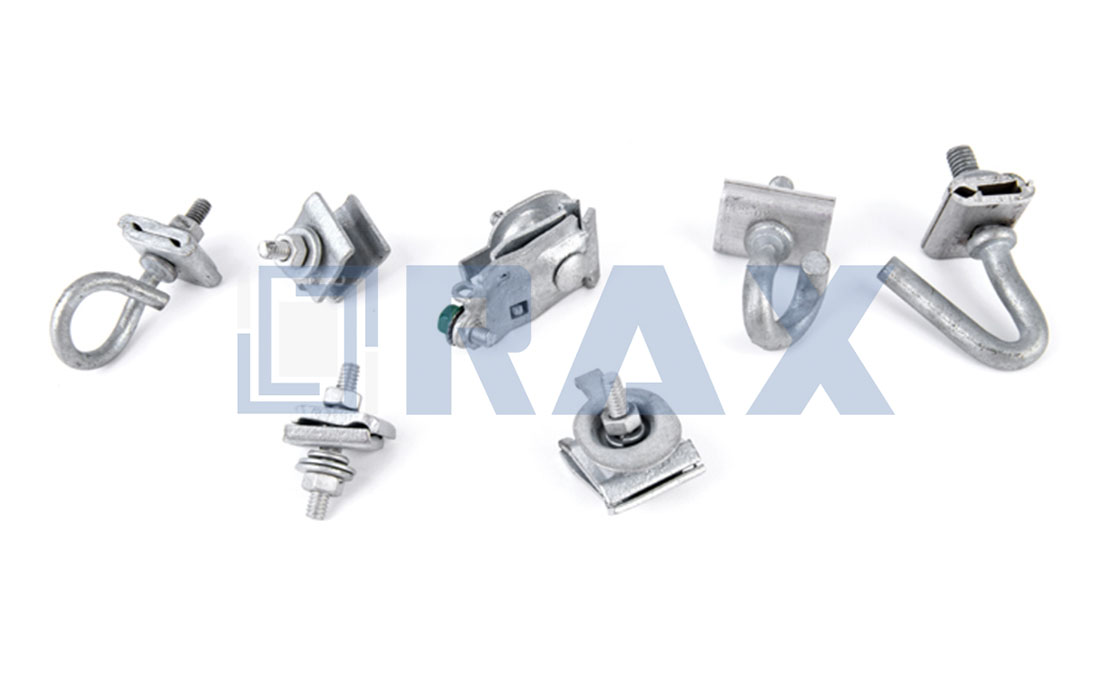

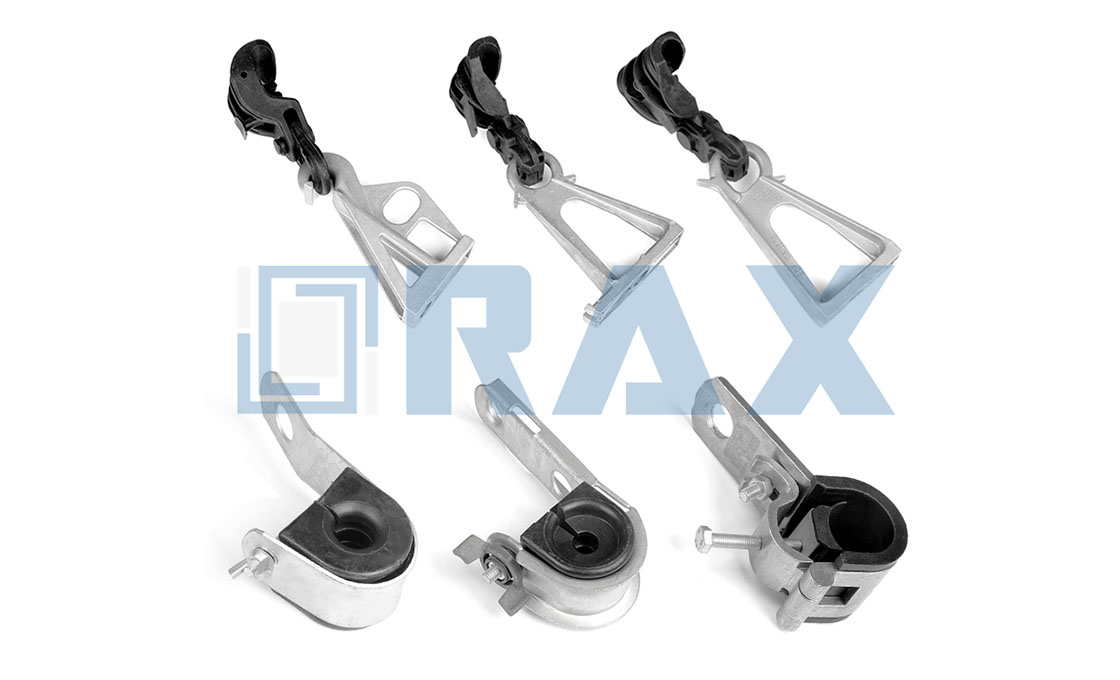

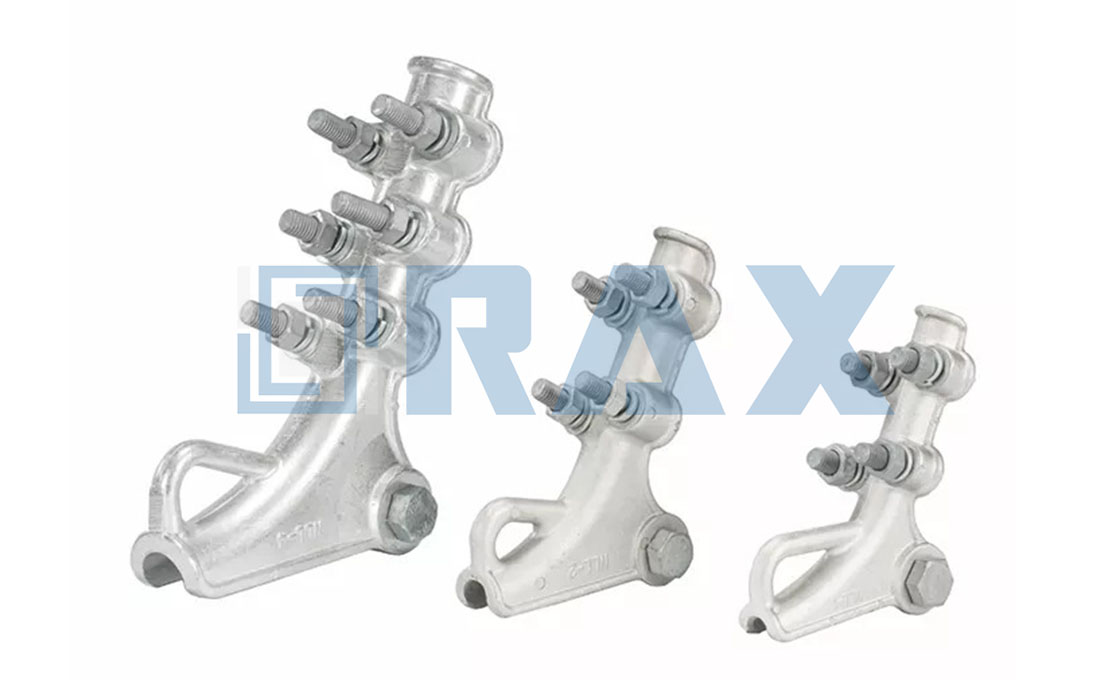

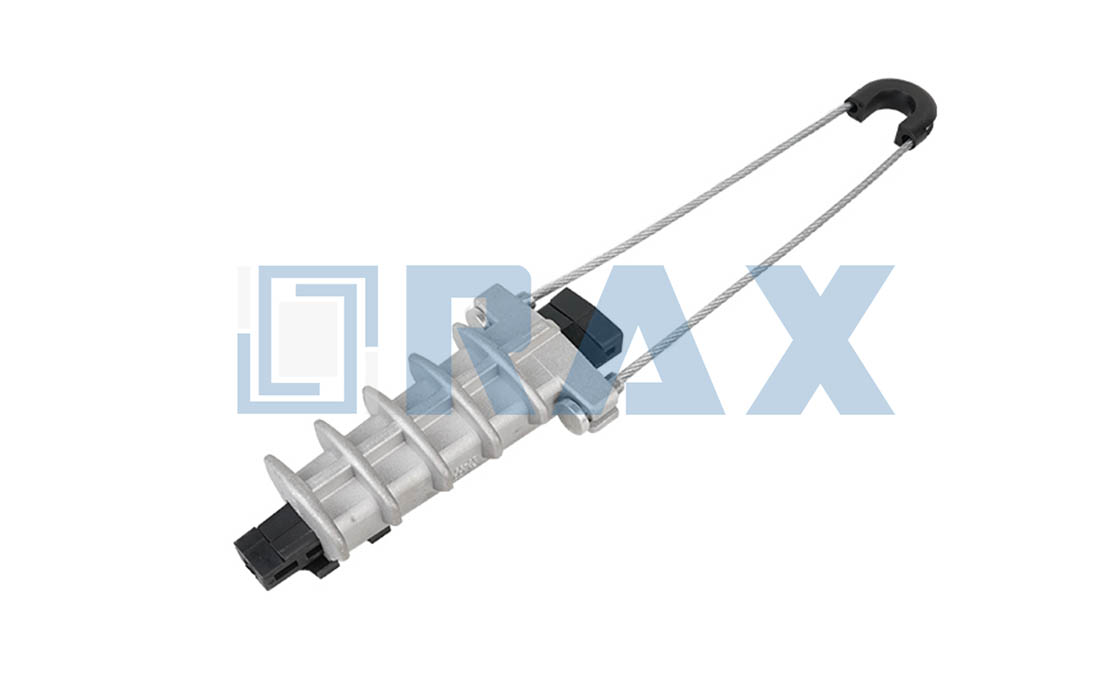

The Span Clamp secures wrapped cable to support wire in aerial construction, providing mid-span drop wire attachment with tension relief and cable management capabilities. It holds cable away from obstacles and enables takeoffs along the span in both lashed and self-supported systems, commonly used in CATV installations and overhead service drops.

Constructed from steel or high-grade aluminum alloy (6063-T6), the clamp features plates, a pigtail bolt (Grade 2 steel), and square nut. Components undergo hot-dip or mechanical galvanizing per ASTM A153 and B695 standards for corrosion resistance. Jaws use 1018 tempered steel or aluminum alloy, with staked threads preventing nut loss during installation.

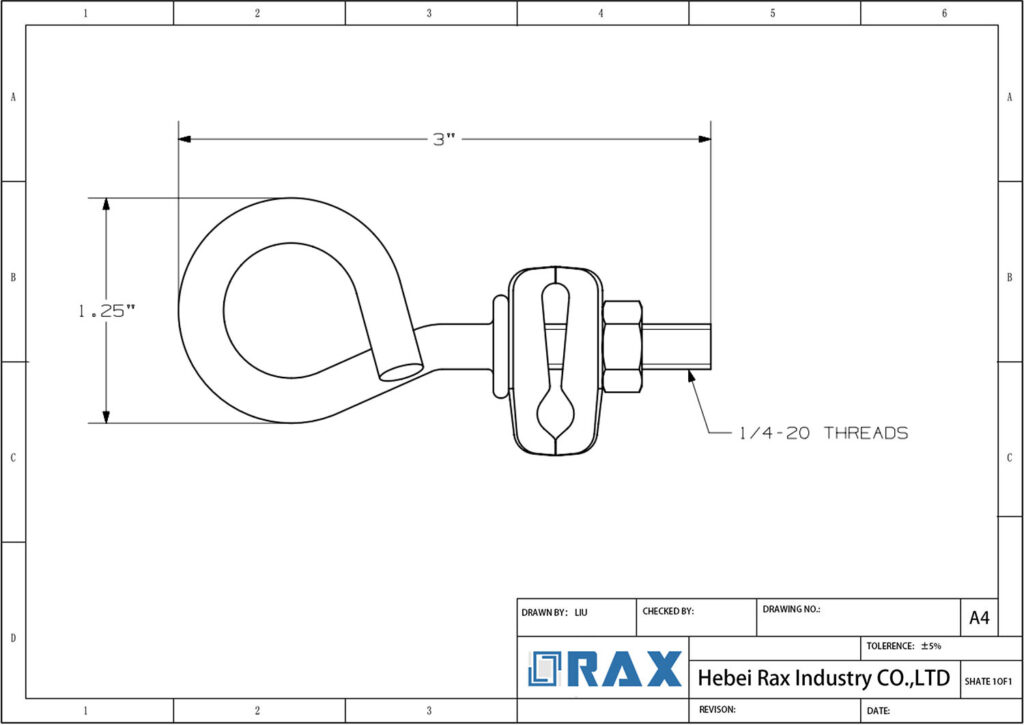

The design incorporates a deep-bent hook or “O” shape for enhanced drop wire retention, minimizing wind whip. The assembly provides positive clamping action to resist slippage on messenger strands, with a clamping range accommodating strand sizes from 1/4″ to 7/16″. Tensile strength of jaws and bolt exceeds 75,000 PSI.

Span Clamps meet Bellcore CA08391 specifications and relevant ASTM standards, ensuring compliance with communication hardware requirements. The corrosion-resistant construction delivers reliable performance in demanding outdoor environments, supporting easy installation and secure attachment across global aerial deployments.

Span Clamp Manufacturer for Secure Aerial Installations

The RaxPower Span Clamp is a cable clamp accessory used to span clamp cable and the support wire for securing wrapped cable. It is ideal for drop cable installations where it attaches to the strand to accept the bail of Drop Wire Clamps or wrap the support wire, holding cable away from obstacles in aerial construction and reducing cable shaking.

RaxPower was established in 2003 and is located in Hebei Province, China. With over 21 years of manufacturing and exporting experience, we are a trusted factory and early innovator in pole line hardware.

Our Span Clamps are produced using advanced hot forging technology for greater strength and accurate sizing, ensuring high tensile strength ≥ 500 PSI. They are made from high-quality materials like 5052 aluminum alloy or hot-dip galvanized steel that meet ASTM specifications. We maintain strict quality control with raw material selection, multi-stage testing, and automation to ensure 100% quality, while our hot-dip galvanizing process follows ISO 1461 with a mean coating thickness over 85 microns for superior corrosion resistance.

Please feel free to send your inquiry; we respond within 24 hours to meet your needs.

| Parameter | Specification |

|---|---|

| Application | Used for mid-span drop wire take-offs in aerial construction, providing attachment for drop wire clamps and tension relief for drop wires in CATV installations and overhead service drops. |

| Clamping Range | 1/4″ to 7/16″ |

| Tensile Strength | Exceeds 75,000 PSI |

| Components | Pigtail bolt, two clamp plates (jaws), square nut |

| Material – Bolt/Nut | Grade 2 Steel |

| Material – Jaws | 1018 tempered Steel or 6063-T6 Aluminum |

| Galvanizing – Bolt/Nut | Hot-dip galvanized to ASTM A153 |

| Galvanizing – Jaws | Mechanically galvanized to ASTM B695 |

| Standards | Meets Bellcore CA08391, ASTM A153, ASTM B695 |

| Features | Threads staked to prevent nut loss; deep-bent hook or “O” shape for better retention and reduced wind whip; positive clamping action to resist slippage. |

Frequently Asked Questions (FAQS)

What is the primary use of a span clamp?

The span clamp is used for drop wire clamp attachment at the mid-span, providing drop wire takeoffs and relieving tension on the drop wire.

How do your span clamps meet certification and reliability standards for electric utility applications?

Our span clamps meet industry standards including Bellcore CA08391 and ASTM specifications for galvanizing. They undergo rigorous testing including load tests and gauge tests per IEC standards, ensuring high tensile strength and reliability. Products have passed SGS tests and tests by authoritative research institutes, confirming compliance and durability for utility use.

What range of strand sizes can the span clamp accommodate?

It accepts a strand size range from 1/4 to 7/16 .

What materials are used in the construction of the span clamp?

The clamp is constructed from steel or aluminum alloy, with components including clamp plates, a pigtail bolt, and a square nut. Specific materials include Grade 2 Steel for bolts and nuts, and 1018 tempered Steel or 6063 Aluminum for jaws, with tensile strength of jaws and bolt exceeding 75,000 PSI.

What corrosion protection and durability features do your span clamps have for long-term outdoor use?

Our span clamps feature hot-dip galvanizing that meets ISO 1461 standards, with mean coating thickness exceeding 85 microns. Bolts and nuts are hot-dip galvanized to meet ASTM A153, while jaws are mechanically galvanized to meet ASTM B695. This ensures long-term durability and resistance to rust in harsh environmental conditions for decades of reliable use.

How do I install the span clamp?

To install, position the clamping plates on top of the messenger strand and tighten the clamping nut. Then, insert the drop wire, drop wire clamp, or wire grip into the hook, and pull the drop wire against the hook towards the service area.

Can you support large-scale projects with bulk orders and guarantee on-time delivery?

We have extensive experience in handling bulk orders and utilize automated manufacturing to ensure consistent quality and timely delivery. Our dedicated team provides fast response and support for project-based needs, leveraging over 20 years of expertise and global delivery capabilities to meet your schedule and volume requirements.

Do you offer OEM or custom manufacturing options to help us achieve cost savings and brand consistency?

Yes, we offer OEM and ODM services, allowing for customized solutions at preferential factory prices. Our ISO-certified processes ensure consistent quality that protects your brand, with options for a broad catalog of products tailored to your specifications for cost-effective and reliable hardware.

Get A Quick Quotation Today