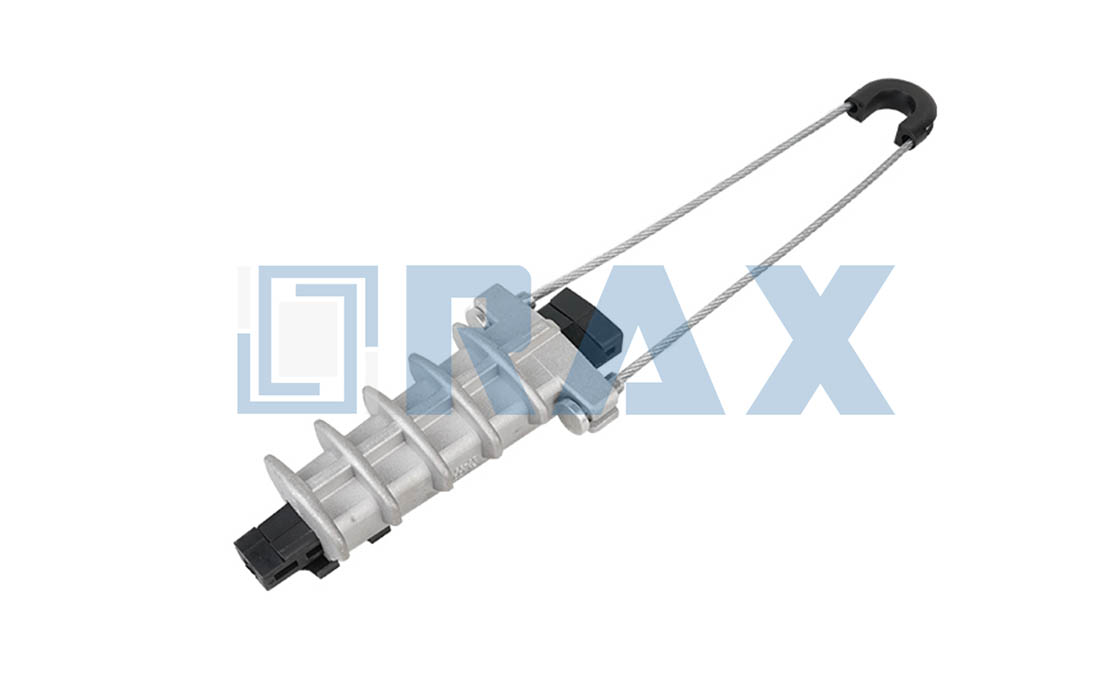

A drop wire clamp anchors fiber optic drop cables to poles, walls, facades, or messenger wires in aerial networks without damaging the cable. It withstands cable tensile strength, wind loads, UV exposure, rain, and temperature changes while enabling safe last-mile connectivity in FTTH, FTTx, CATV, and telecom applications.

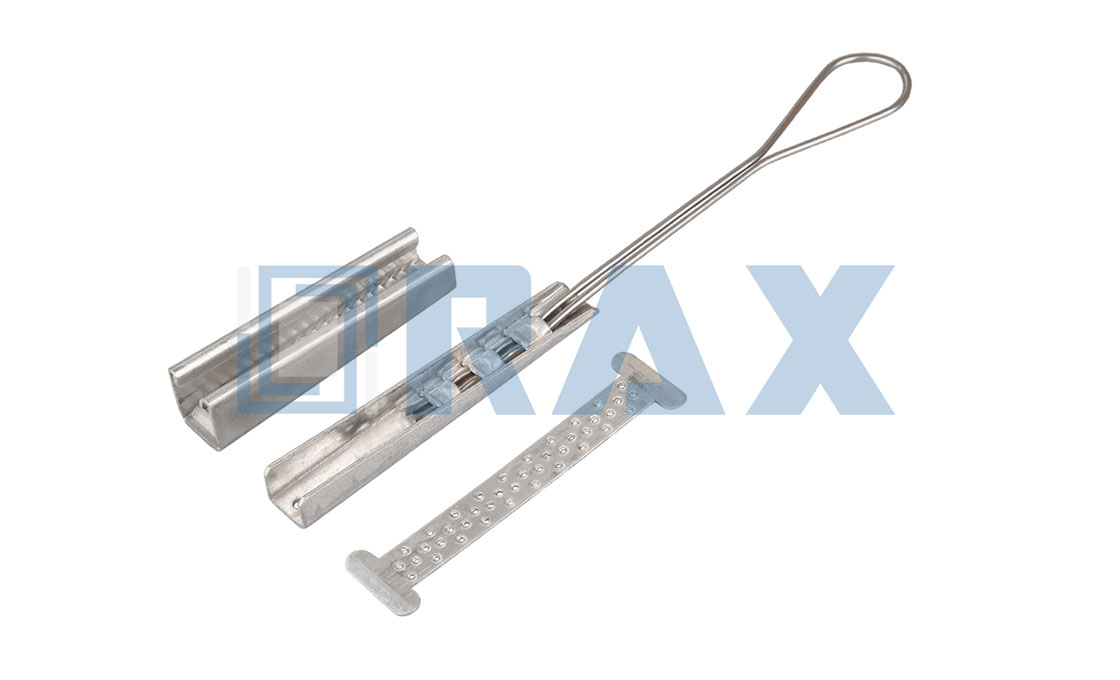

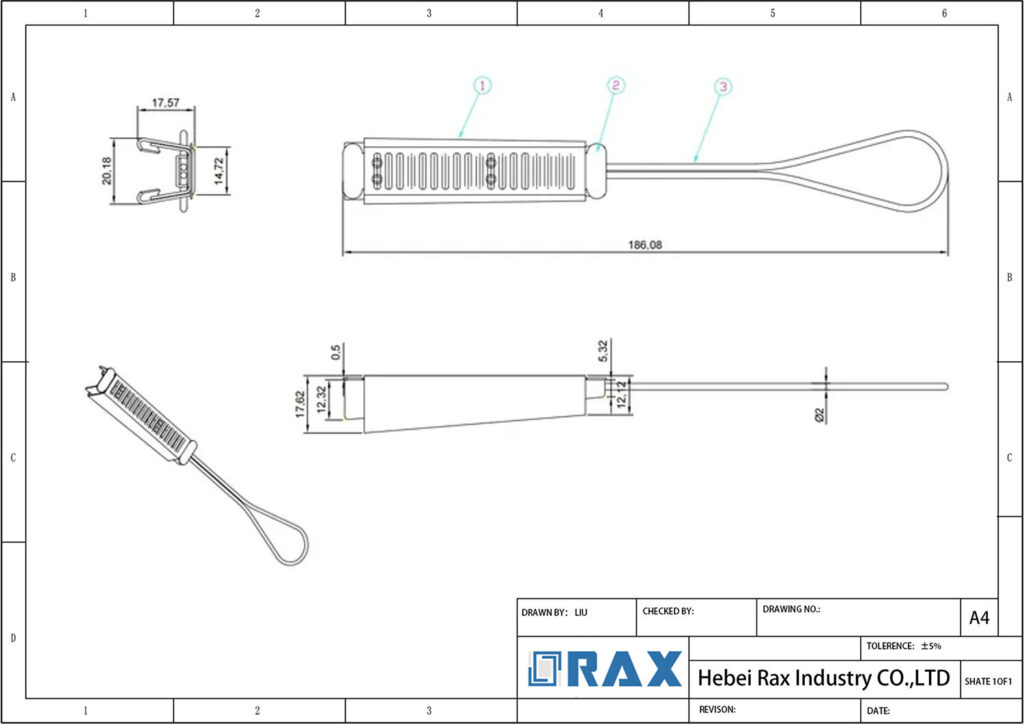

Drop wire clamps use UV-resistant polymers, stainless steel, aluminum, or galvanized steel with components like stainless-steel bails and dimpled shims. Materials resist moisture, corrosion, and UV degradation, with glass-filled polyamide variants offering enhanced temperature and torsion resistance. Clamps handle mechanical loads up to 555 pounds and operate from -50°C to +60°C, accommodating cable diameters up to 0.200 by 0.410 inches.

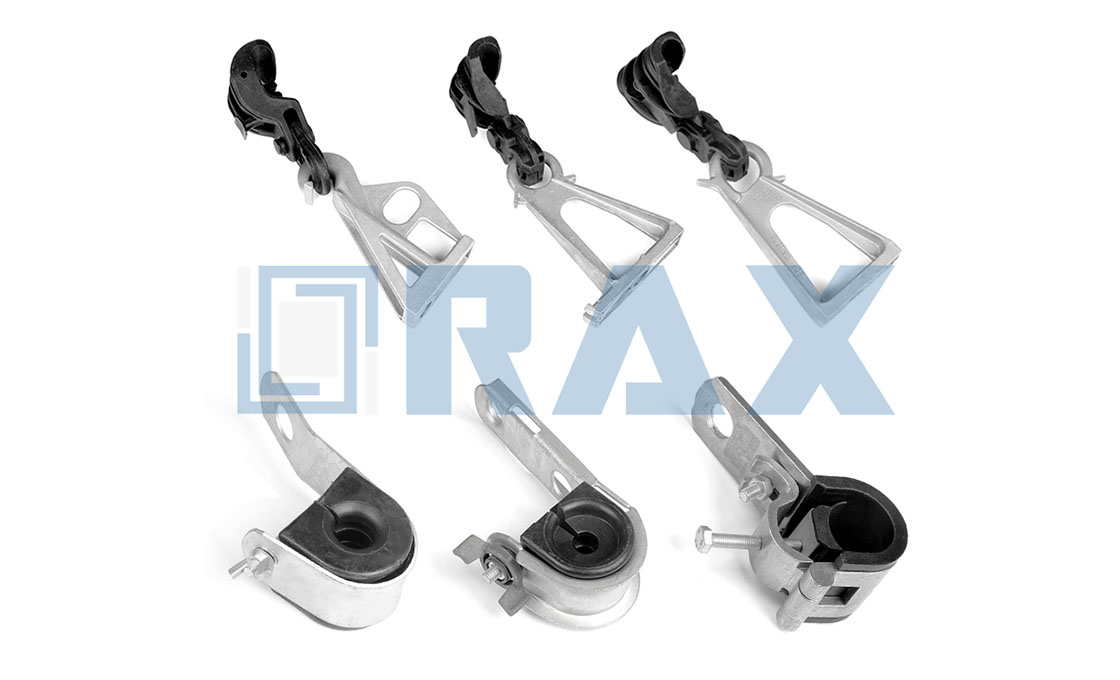

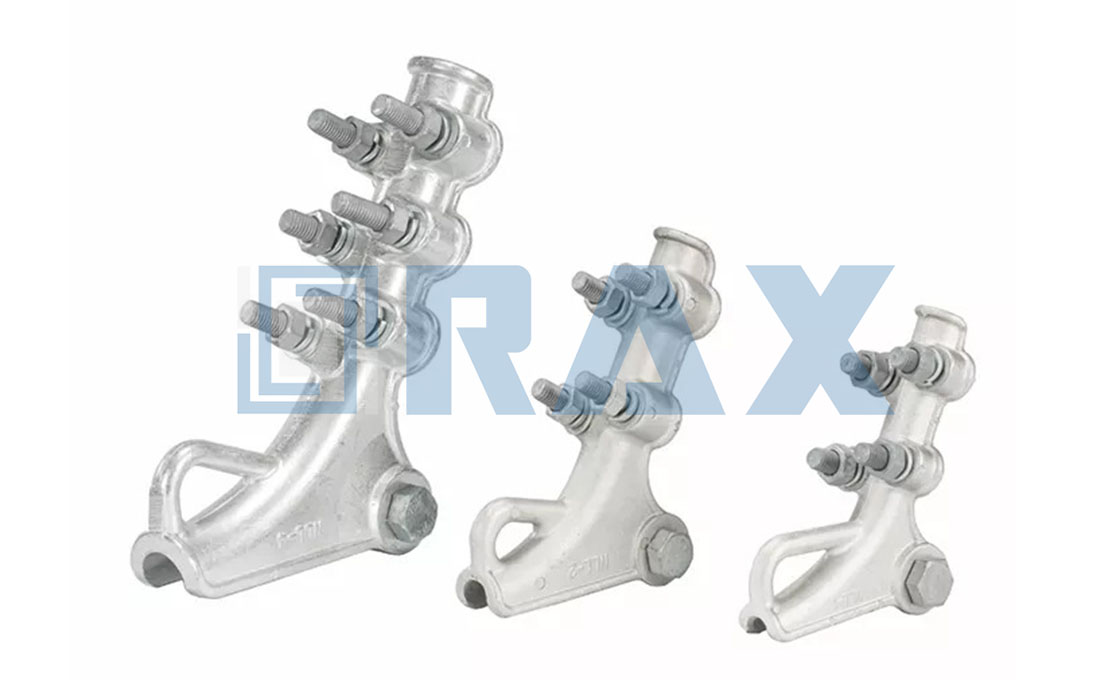

Available types include flat cable clamps for flat optical fiber cables, round cable clamps for round cables, S-type clamps for messenger wires, wedge-type clamps for fast installation across various shapes, and last-mile clamps for end-user connections. Installation involves placing the cable in the clamp groove and securing it with the provided shim, wedge, or wheel, then attaching to pole brackets or wall-mounted hardware. Selection depends on cable shape, diameter, jacket material, mechanical load, bending radius, and installation environment to ensure proper cable security without exceeding rated mechanical strength.

Trusted Quality from RaxPower Drop Wire Clamp Factory

Welcome to RaxPower, a leading manufacturer, supplier, and factory based in Hebei Province, China, specializing in a wide range of pole line hardware and telecom accessories. With over 20 years of manufacturing expertise, we are a direct producer of reliable, factory-direct drop wire clamps, ensuring high-quality solutions for telecommunication applications.

Our Drop Wire Clamp provides an efficient and secure method for suspending cables on poles, building walls, or other structures, designed with high-grade materials like stainless steel and UV-resistant polymers for exceptional durability, easy installation, and performance in various weather conditions.

We prioritize customer needs by offering customized services for design, size, and color to meet your specific requirements. All our products undergo rigorous quality control, including multi-stage testing and third-party inspections such as SGS, guaranteeing they meet international standards.

Contact us for the following, with support from our engineering team:

- Samples

- Technical datasheets

- A quotation

| Parameter | Specification |

|---|---|

| Material | UV-resistant polymers, stainless steel, aluminum, or galvanized steel |

| Mechanical Load Capacity | Up to 555 lb |

| Working Temperature Range | -50°C to +60°C |

| Cable Diameter Range | Up to 0.200″ x 0.410″ |

| Shim Type | Dimpled or serrated |

| Bail Material | Stainless steel |

| Applications | FTTH, FTTx, CATV, Telecom |

| Installation Type | Compression or wire-wrap |

| Corrosion Resistance | Yes |

| UV Resistance | Yes |

Frequently Asked Questions (FAQS)

What is a drop wire clamp and what is it used for?

A drop wire clamp is a specialized device designed to anchor and secure fiber optic drop cables during aerial network deployment. It allows safe attachment of cables to poles, walls, facades, or messenger wires without damaging or bending the cable. These clamps are widely used in FTTH, FTTx, CATV, and telecom applications to ensure reliable last-mile connectivity.

What are the key benefits of using a drop wire clamp?

Drop wire clamps provide a stable and durable grip that withstands cable tensile strength, wind loads, and environmental impacts. They offer long service life, easy installation without tools in some designs, and protection against cable damage by preventing sharp bends and jacket abrasion. They are cost-effective, maintenance-free, and ensure reliable connectivity.

What types of drop wire clamps are available?

Different aerial deployments require different clamp designs: flat cable drop clamps for flat optical fiber cables, round cable drop clamps for round optical fiber cables, S-type clamps to secure messenger wire of drop cables, wedge-type clamps for fast installation and various cable shapes, and last-mile clamps designed for end-user connections. Each type is engineered for specific cable dimensions and mechanical performance requirements.

What materials are drop wire clamps made from and how do they handle environmental challenges?

Drop wire clamps are typically made from stainless steel for the bail and UV-resistant polymer for the body, with some using aluminum or galvanized steel. These materials provide corrosion resistance, high strength, and abrasion resistance while withstanding harsh outdoor conditions. The clamps operate reliably in temperatures from -50°C to +60°C, resisting UV exposure, rain, ice, and wind while maintaining mechanical integrity.

How do I properly install a drop wire clamp?

Place the fiber cable inside the groove of the clamp, then secure it gradually with the shim, wedge, or wheel provided, ensuring the cable is fixed without movement. Finally, attach the clamp to the pole bracket or wall-mounted hardware at the aerial point. Always verify that the clamp groove matches your cable size and check the cable's rated mechanical strength to avoid exceeding its minimal breaking load.

What should I consider when choosing the right drop wire clamp?

Consider the cable shape (round, flat, or figure-8), cable diameter and jacket material, mechanical tension load and bending radius, and the installation environment such as short-span, medium-span, or long-span aerial lines. A properly chosen clamp will secure the cable without damage while providing sufficient mechanical strength, and in case of accidents like wind or ice load, it may release the cable to protect the fiber signal.

Are your clamps suitable for specialized applications like railway electrification?

RaxPower's drop wire clamps are engineered for diverse applications, including FTTH, FTTx, CATV, telecom, and railway electrification. We offer specialized designs such as S-type and wedge-type clamps that provide high mechanical strength, durability, and compliance with relevant standards. These clamps secure cables without damage, prevent vibration-related issues, and are tested for harsh conditions.

How do your drop wire clamps ensure long-term reliability and compliance with industry standards?

RaxPower employs strict quality control measures, including raw material selection and multi-stage testing. All products undergo load testing and gauge tests according to international standards, ensuring 100% quality and durability. Our manufacturing process ensures clamps meet the performance requirements for grid maintenance and expansion.

Can you handle large-volume orders and ensure on-time delivery for major infrastructure projects?

With 21 years of manufacturing experience, RaxPower operates 17,000 square meters of production workshops and 5,000 square meters of warehouses, supported by over 170 employees. We utilize automated machines and optimized supply chains to maintain accurate sizing, uniform quality, and efficient production. This enables us to offer competitive project-based pricing and reliable on-time delivery for bulk orders.

Do you offer OEM customization options to help reduce production costs for manufacturers?

Yes, RaxPower provides OEM and custom branding options, allowing for tailored designs, sizes, and specifications. Our in-house manufacturing capabilities, including hot forging and advanced machinery, ensure perfectly consistent quality and significant cost savings. This approach helps OEM clients achieve lower production costs without compromising on reliability or brand protection.

Get A Quick Quotation Today