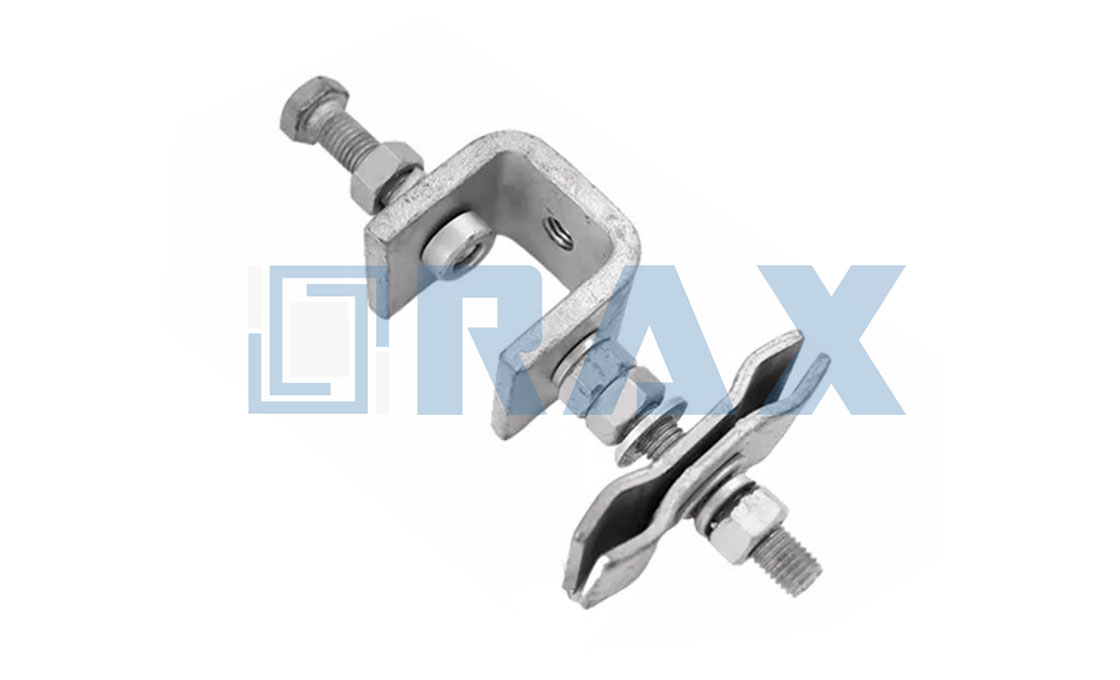

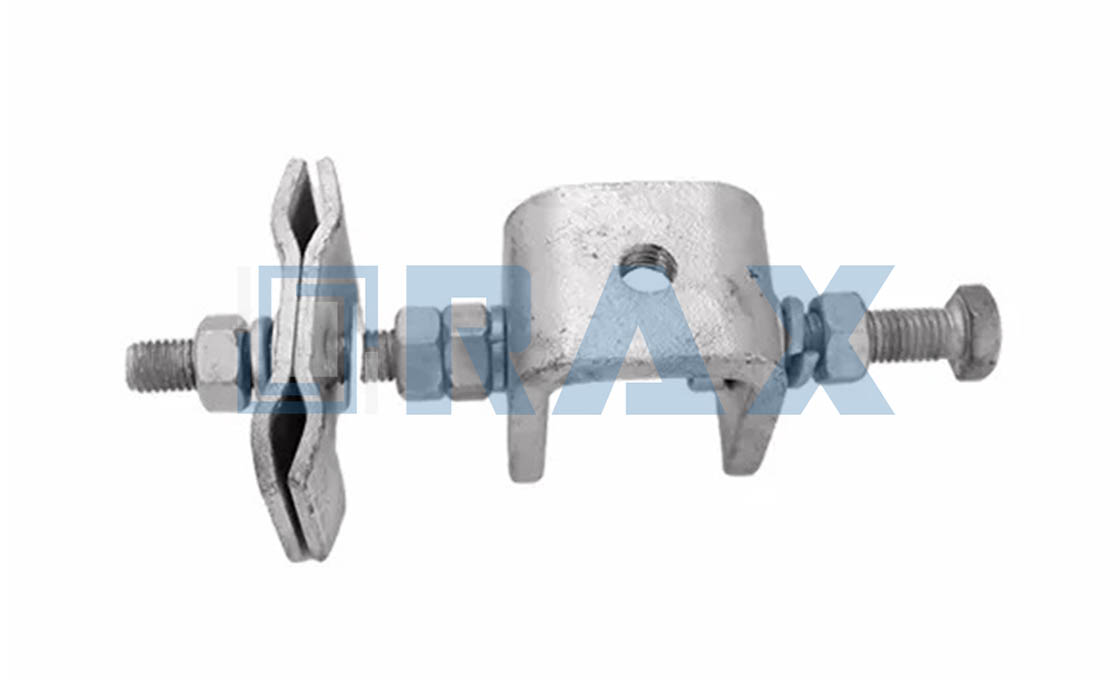

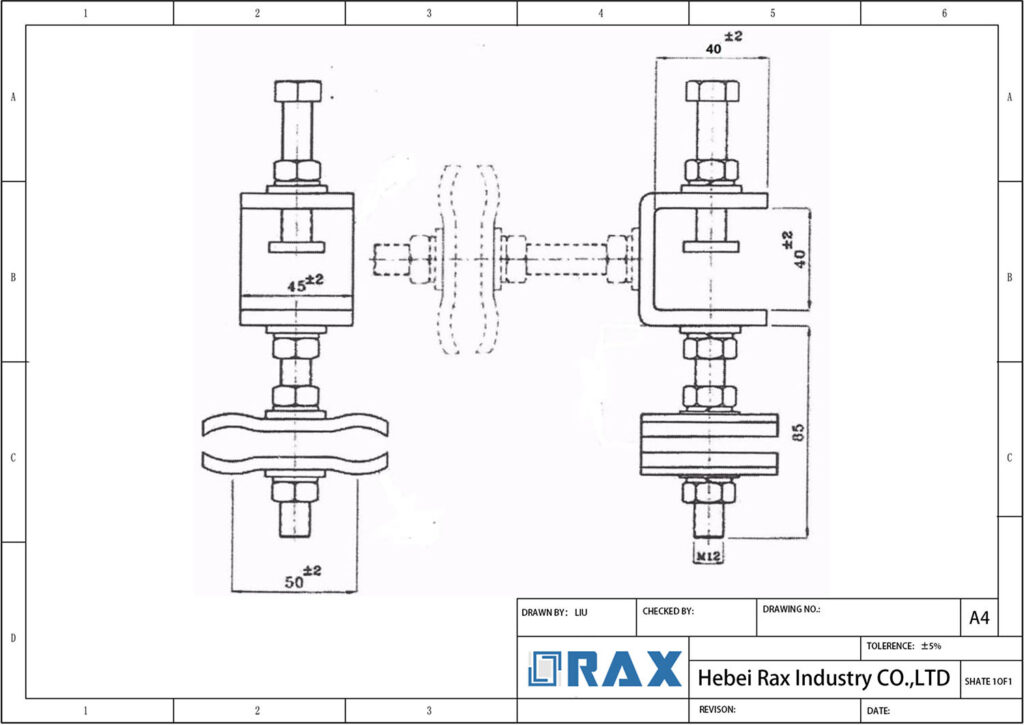

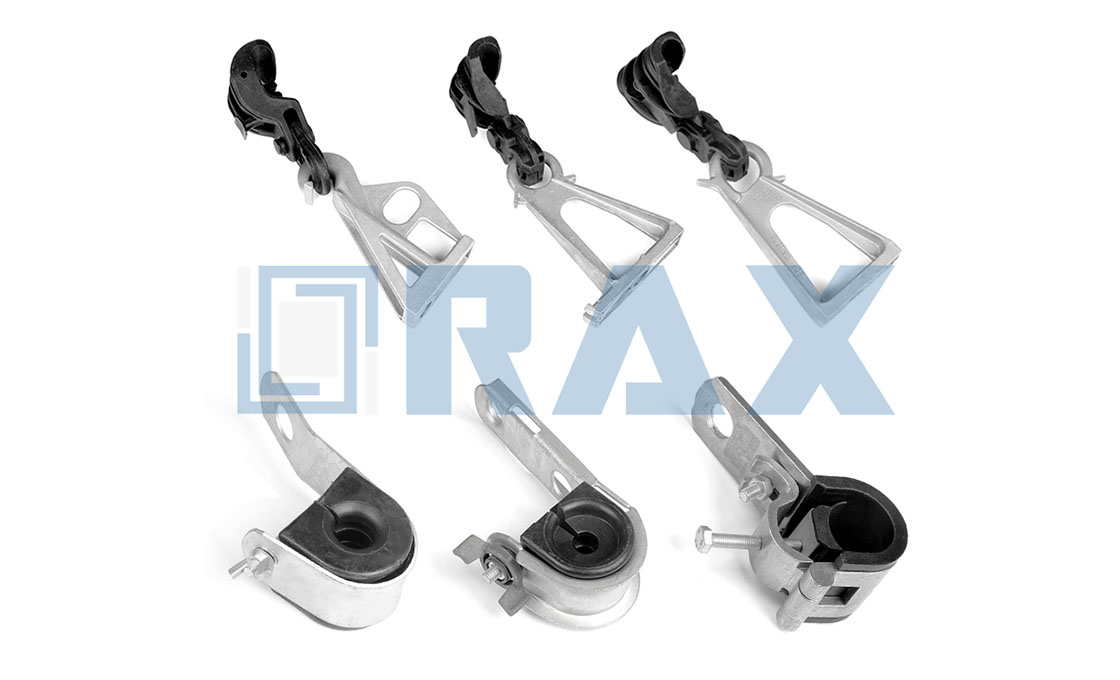

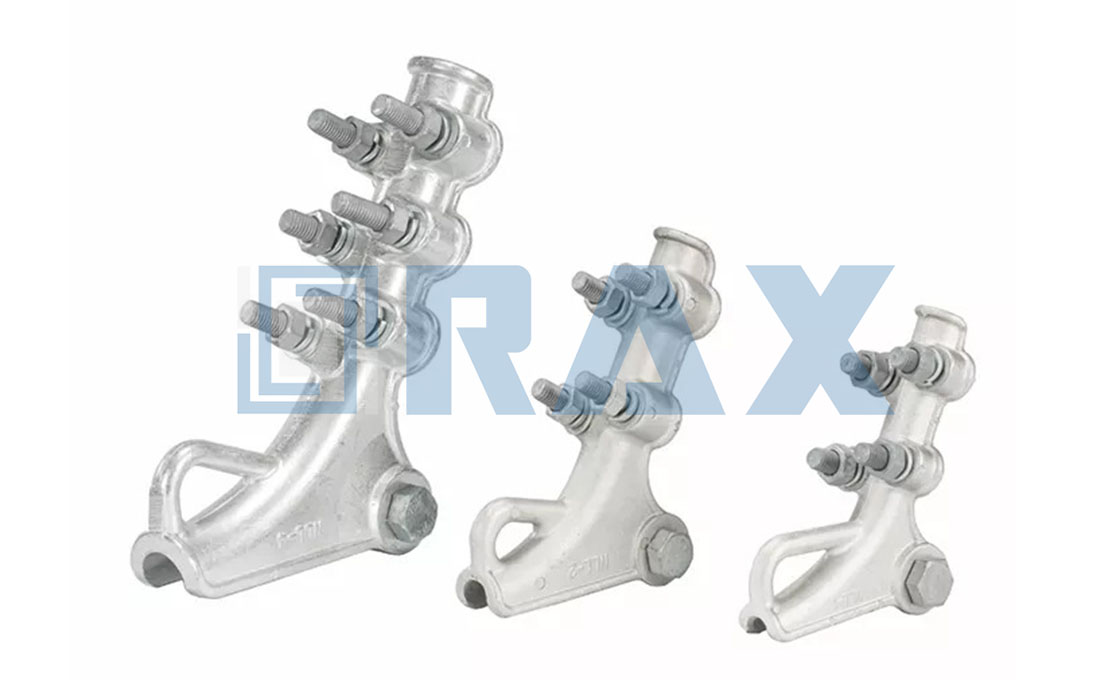

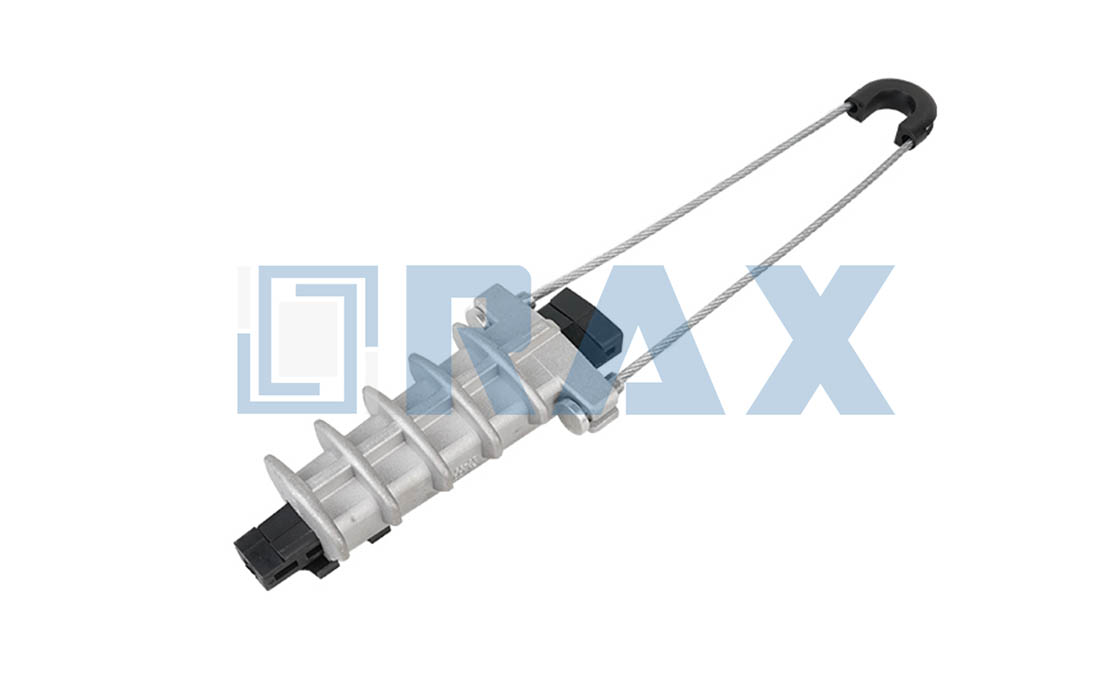

The downlead clamp secures and guides optical cables, such as Optical Ground Wire (OPGW) and All-Dielectric Self-Supporting (ADSS) cable, from transmission structures to splice boxes. Installed at 1.5 to 2.0 meter intervals on poles and towers, the clamp maintains proper cable alignment and spacing during down lead and jump connections in telecommunications and power distribution systems.

The clamp features slip strength exceeding 100 pounds to maintain cable position under stress. Lattice adapters include break-away bolts for precise torque application, while steel tower guide clamps use adapters that eliminate structural drilling. Banding adapters provide mounting flexibility, and insulated versions incorporate a 15 kilovolt (kV) insulator for electrical protection. Materials include aluminum, stainless steel, and Ethylene Propylene Diene Monomer (EPDM) rubber for durability and environmental resistance.

The design accommodates cable diameters from 9.0 millimeters (mm) to 19.0 mm, with models specific to pole or tower applications. Tower brackets support angle thicknesses from 0.25 to 0.75 inches, and parallel grooves in the cushion minimize compressive forces on cables. Aluminum downleads may provide an electrical bonding path in OPGW applications. Installation uses mounting accessories compatible with wood, concrete, metal, and lattice towers, with break-away bolts preventing over-tightening and distributing cable weight evenly.

Downlead Clamp Supplier for Enhanced Cable Safety

RaxPower is a manufacturer of downlead clamps used on electrical and telecommunication systems. Our clamps secure and support cable or conductor hardware, preventing excessive stresses caused by weight or external forces like wind. They reduce the risk of damage or disconnection and maintain proper spacing between cables.

Drawing from historical evidence, downlead clamps ensured safety in iconic projects such as the Empire State Building, showcasing their real-world importance. RaxPower’s downlead clamps install easily, provide proper spacing, and hold strength without damage to the cable, leveraging over 21 years of expertise and advanced hot forging technology for enhanced durability.

As a full-service partner, we offer a full line of OPGW downlead clamps for any application, from poles to towers. Serving the needs of customers in a variety of market applications, including telecommunications, power distribution, and antenna installations, we ensure reliability through strict quality control and testing.

See the major markets we serve and try out RaxPower solutions for secure and efficient cable management.

| Parameter | Specification |

|---|---|

| Cable Diameter Range | 9.0 mm to 19.0 mm |

| Slip Strength | >100 lbs |

| Materials | Aluminum, stainless steel, EPDM rubber |

| Installation Interval | 1.5 m to 2.0 m |

| Mounting Options | Lattice adapters with break-away bolts, banding adapters |

| Insulation Rating | 15 kV (for insulated versions) |

| Tower Angle Thickness | 0.25 inches to 0.75 inches |

| Weight | Approximately 0.55 kg to 1.0 kg (varies by model) |

| Additional Features | Parallel grooves in cushion design to minimize compressive clamping forces |

Frequently Asked Questions (FAQS)

What is a downlead clamp used for?

A downlead clamp secures and supports optical cables like OPGW and ADSS from the top of the structure to the splice box during down lead and jump connections, preventing sagging, swaying, and damage from wind or environmental forces.

What types of downlead clamps are available?

Options include rubber and metal clamps for both poles and towers, cable clamps, fiber optic cable clamps, combination clamps, and adjustable clamps to accommodate different cable sizes and installation requirements.

What materials are downlead clamps made from?

Downlead clamps are constructed from aging-resistant rubber, aluminum alloy, stainless steel, galvanized steel, and EPDM, with components including silicone for insulation to withstand harsh environmental conditions.

What range of models do you offer?

We provide clamps for poles and towers accommodating cable diameters from 9.0 mm to 19.7 mm, with adjustable designs for electrical power distribution, telecommunications, and railway electrification. Our catalog includes custom mounting accessories for wood, concrete, metal, or lattice structures.

How do your clamps protect fiber optic cables in OPGW and ADSS installations?

Our clamps feature slip strength exceeding 100 lbs, proper cable spacing, lattice adapters with break-away bolts for precise torque, and options with 15 kV insulated protection. Constructed from EPDM rubber, aluminum, and stainless steel, they minimize compressive force while ensuring durability and cable integrity.

How do your downlead clamps ensure compliance with industry standards?

Clamps undergo strict quality control including load testing and gauge tests per IEC 120 standards, with hot-dip galvanization exceeding 85 microns mean coating thickness per ISO 1461. Multi-stage testing and automated processes ensure every product meets rigorous performance and safety requirements.

How do I install a downlead clamp?

Assess and clean the mounting surface, position the clamp, mark and drill holes, secure with fasteners to the recommended torque, insert and secure the cable, test alignment and tension, and perform grounding if applicable.

What is the recommended spacing for installation?

Install one set of downlead clamps every 1.5 to 2.0 meters along the cable run to ensure proper support and stability.

How do I choose the right downlead clamp?

Consider cable type and diameter, environmental conditions, load-bearing capacity, installation method, material durability, cost, and compliance standards. Ensure compatibility with your structure type and specific application needs.

What is your capacity for large-volume orders and on-time delivery?

With 21 years of experience, RaxPower operates 17,000 square meters of production facilities and 5,000 square meters of warehouses with 170 employees. Automatic machines and semi-automatic molds enhance efficiency for reliable bulk supply, optimized logistics ensure on-time delivery, and flexible payment terms accommodate project-based requirements.

Get A Quick Quotation Today