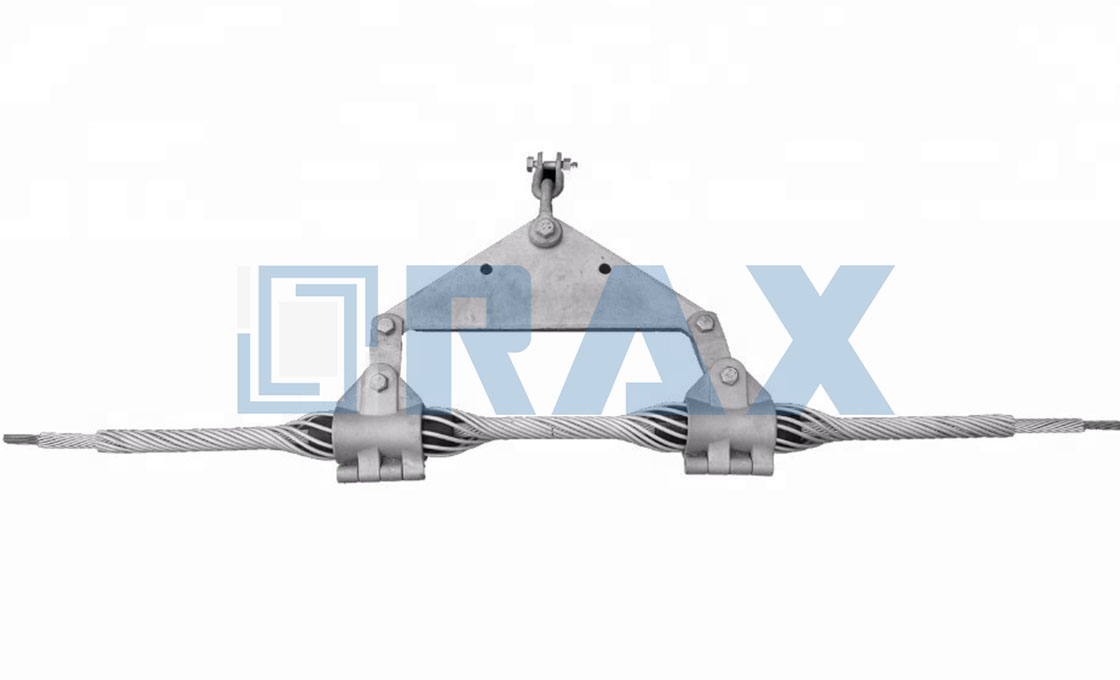

The Armor Grip Suspension is a specialized clamp engineered to reduce static and dynamic stresses at conductor support points, protecting conductors from oscillations and safeguarding against impulse and power flash-over in overhead power line systems. Recommended as superior to armor-clamp combinations, it minimizes bending stress, compression stress, and abrasion while providing reliable performance that contributes to conductor longevity and integrity.

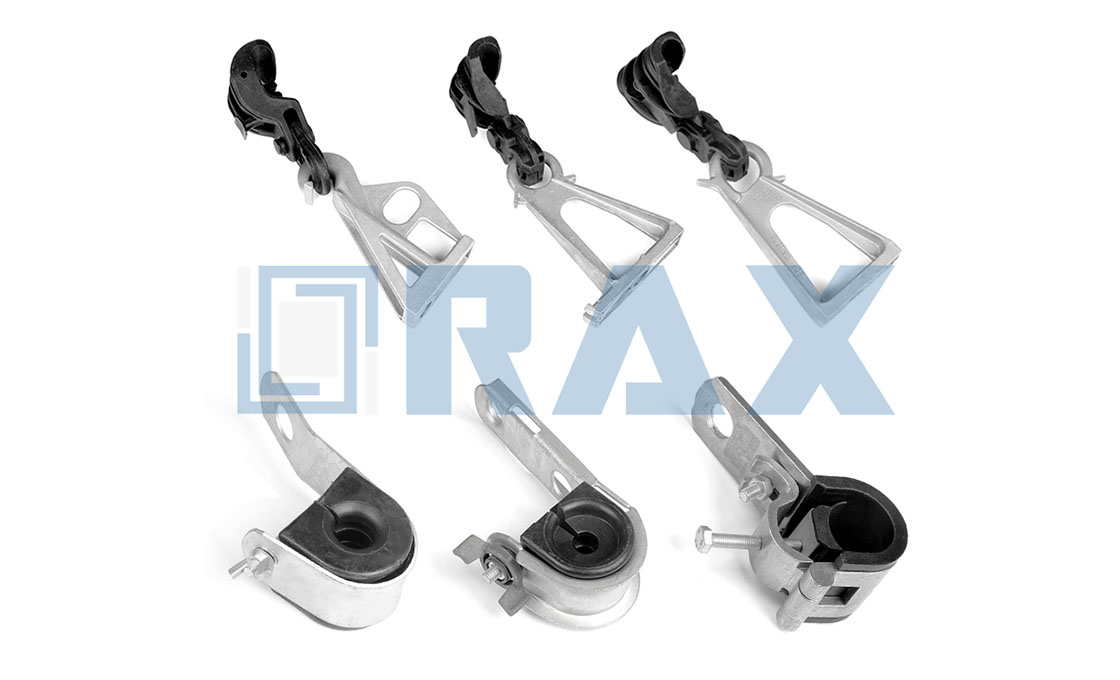

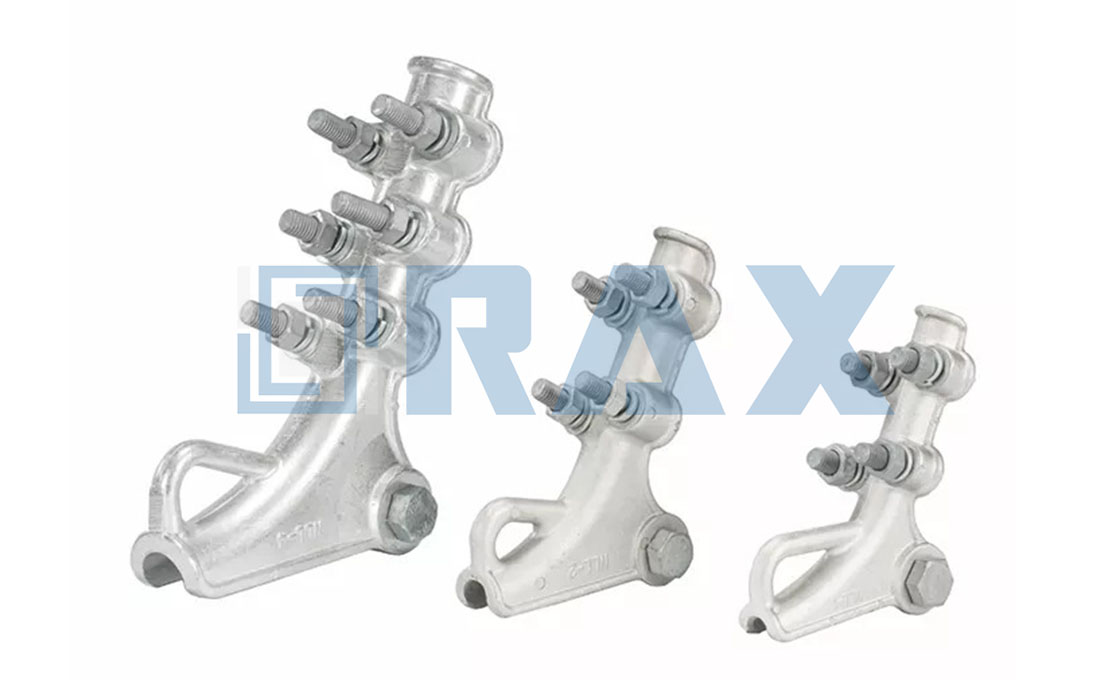

The housing features galvanized steel construction for cable diameters of 0.272 to 0.500 inches or high-strength aluminum alloy casting for conductor diameters from 0.482 to 2.233 inches. An elastomer insert provides resistance to ozone attack, weathering, extreme temperature variations, and compression set. Rods incorporate ball ends for non-Extra High Voltage (EHV) applications or parrot-bill ends for EHV applications at 345 kV and above.

Technical specifications include a standard version for continuous temperatures up to 200°C and a high-temperature version for 250°C continuous conductor temperature. The clamp accommodates line angles up to 30 degrees for single supports, with double support arrangements recommended for angles between 30 and 60 degrees. Initial slip load reaches approximately 20% of the conductor’s rated breaking strength under unbalanced conditions.

Applications include aluminum-based conductors, Alumoweld, galvanized steel strands, Aluminum Conductor Steel Reinforced (ACSR), all-aluminum, and aluminum alloy types. It repairs fatigue-damaged conductors by applying over preformed armor rods and is compatible with right-hand lay conductors in standard and EHV settings.

Armor Grip Suspension Supplier for Enhanced Cable Protection

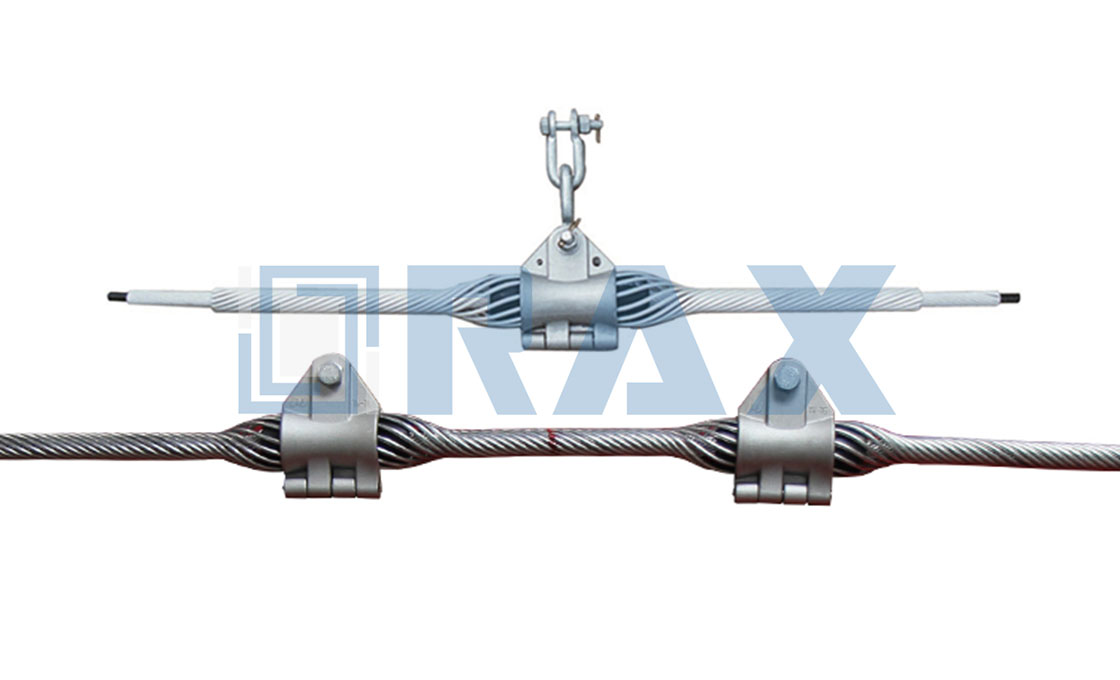

Armor grip suspension, also known as AGS suspension clamp, is essential for supporting and protecting ADSS/OPGW cables in telecommunications and electrical systems.

As an ISO certified manufacturer, supplier, and exporter, RaxPower has 21 years of experience in this industry, enabling us to offer cost-effective OEM partnerships for both custom and standard solutions. Our commitment to reliability and unmatched service is backed by extensive manufacturing expertise.

The Armor Grip Suspension is made from robust materials such as galvanized steel and aluminum alloy, ensuring high tensile strength and corrosion resistance.

Technical specifications cover various cable diameters and span lengths, from 100m to 800m, with options for single or double suspension based on application needs. Installation is straightforward, with clear procedures to ensure safety and efficiency.

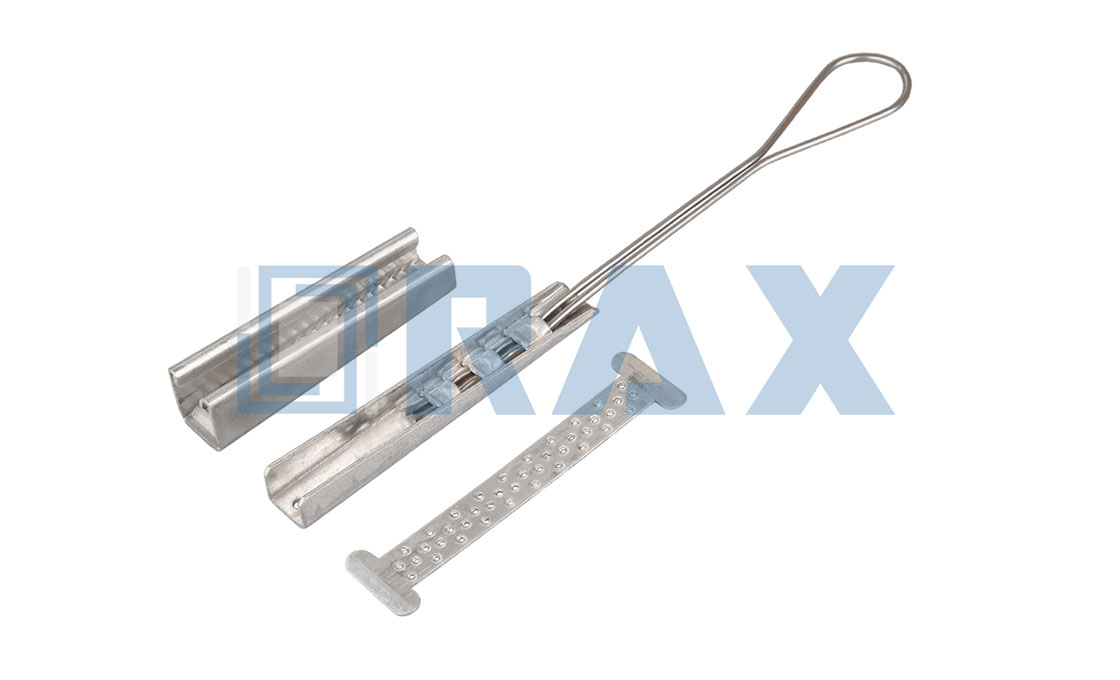

We utilize advanced hot forging technology for greater strength and precise sizing in our products. Our quality control includes:

- Raw material selection

- Multi-stage testing

- Compliance with international standards

Contact us now to provide you with free sample testing and preferential quotations.

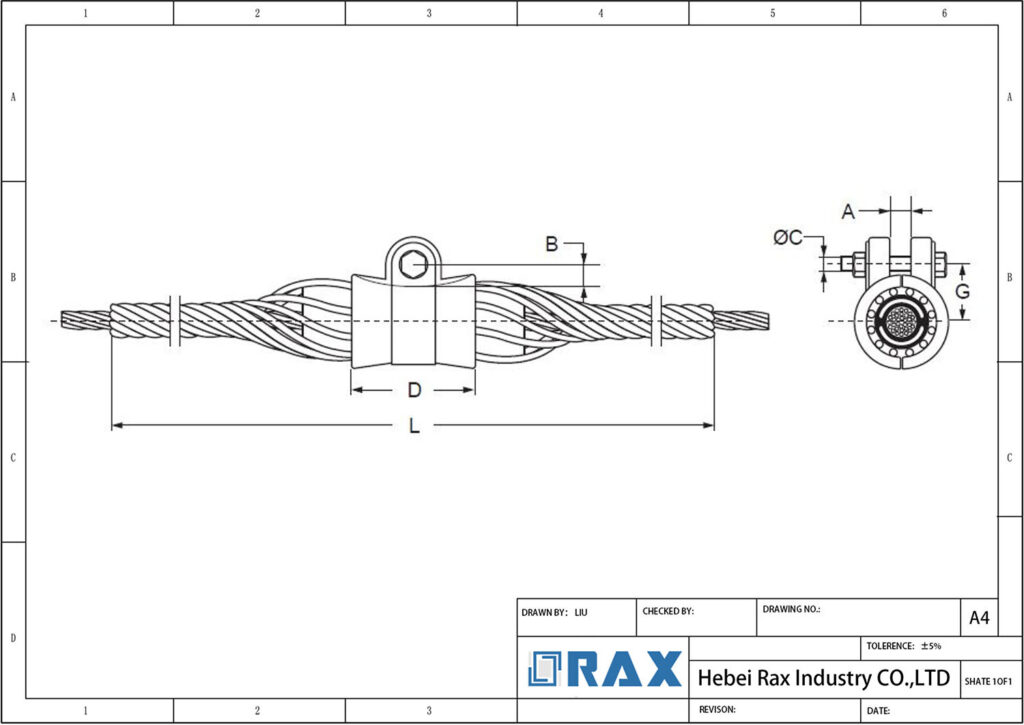

| Parameter | Specification |

|---|---|

| Housing Material | Galvanized steel for cable diameter range 0.272–0.500 in; High-strength aluminum alloy casting for conductor diameter range 0.482–2.233 in |

| Insert Material | Elastomer formulated for resistance to ozone attack, weathering, extreme high and low temperature variations, and compression set |

| Rod Material | Aluminum clad steel for ACSR diameter 0.304–0.481 in; Aluminum alloy for ACSR diameter 0.482–2.233 in; Aluminum clad steel for Alumoweld strand diameter 0.272–0.500 in; Galvanized steel for galvanized steel strand diameter 0.272–0.500 in |

| Rod End Types | Ball ends for non-EHV applications; Parrot-bill ends for extra high voltage (EHV) applications at 345 kV and above |

| Thermal Rating | Standard version: Up to 200°C continuous conductor temperature; High-temperature (HT) version: Up to 250°C continuous conductor temperature |

| Slip Load | Approximately 20% of the conductor’s rated breaking strength under unbalanced conditions |

| Line Angle | Single support: Up to 30°; Double support: 30° to 60° (recommended for angles between 30° and 60°) |

| Applicable Conductors | Aluminum-based conductors, Alumoweld, and galvanized steel strands, including ACSR, all-aluminum, and aluminum alloy types |

Frequently Asked Questions (FAQS)

What is the primary function of the Armor Grip Suspension?

The Armor Grip Suspension reduces static and dynamic stresses at the support point, protecting the conductor or strand against oscillation effects, impulse, and power flash-over. It is superior to traditional armor-clamp combinations for safeguarding conductors from bending stress, compression stress, and abrasion, ensuring long-term reliability and reduced maintenance for utility grids.

What materials are used in the construction of the Armor Grip Suspension?

The housing is made of galvanized steel or high-strength aluminum alloy, depending on the conductor diameter. The insert is an elastomer formulated for resistance to ozone attack, weather, extreme temperature variations, and compression set. Rods are constructed from aluminum alloy, aluminum-clad steel, or galvanized steel based on the conductor type.

What temperature ranges can the Armor Grip Suspension withstand?

The standard version is rated for up to 200°C continuous temperature, while the high-temperature (HT) version can withstand a continuous conductor temperature of 250°C.

What types of conductors are compatible with the Armor Grip Suspension?

It is intended for use on aluminum-based conductors, ACSR, all-aluminum, aluminum alloy, Alumoweld, and galvanized steel strands, and is designed for right-hand lay standard conductors. It is also compatible with ADSS and OPGW cables for telecommunications applications, ensuring technical precision and durability for fiber optic installations.

What are the installation guidelines for line angles with the Armor Grip Suspension?

The maximum recommended line angle for a single support is 30°. For angles between 30° and 60°, the Armor Grip Suspension Double version is recommended to ensure proper support and stress distribution.

Can the Armor Grip Suspension be used for repairing damaged conductors?

Yes, a specially designed Armor Grip Suspension can be applied over preformed armor rods to repair fatigue-damaged conductors, extending their service life.

How does your OEM partnership help us achieve cost savings while maintaining quality?

We act as your OEM partner, providing high-quality, custom-designed suspension clamps manufactured with strict quality control. This allows you to benefit from lower production costs compared to in-house manufacturing, while ensuring perfectly consistent quality that protects your brand.

Can you accommodate large-scale project orders with guaranteed on-time delivery?

With years of experience as a trusted manufacturer and supplier, we offer competitive project-based pricing and prioritize on-time delivery for bulk orders. Our large production capacity and efficient supply chain ensure that we can meet the demands of large-scale projects without delays.

Get A Quick Quotation Today