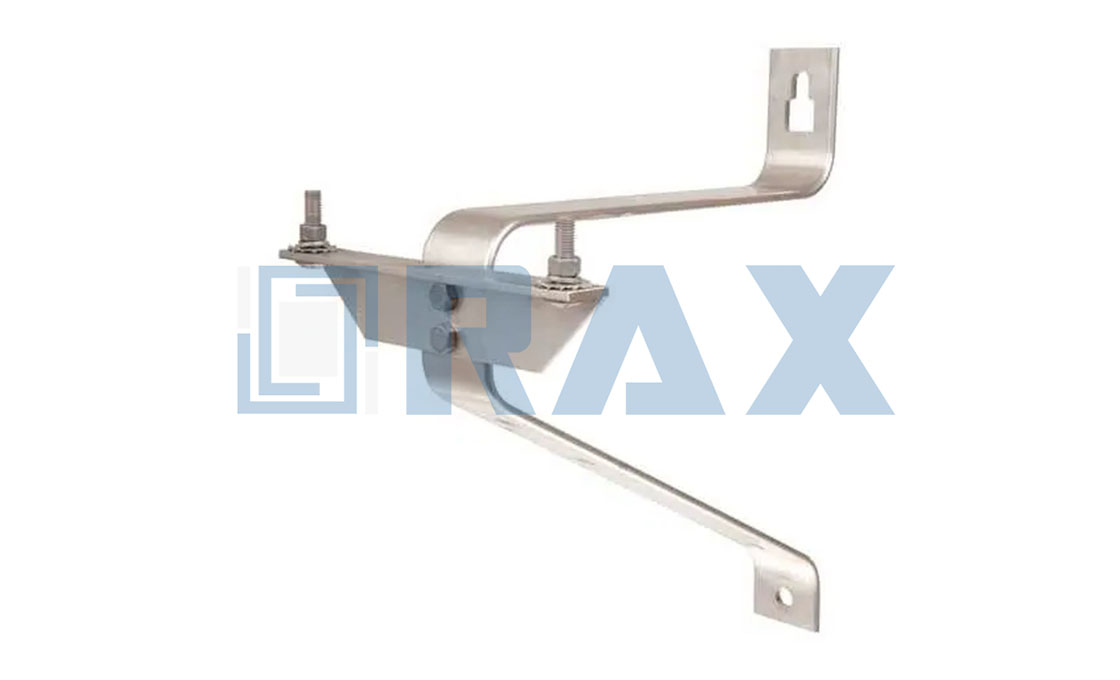

The Tank Mounted Arrester Bracket is a steel component that secures surge arresters to overhead distribution transformer and regulator tanks. It provides a stable mounting point in electrical distribution systems where arresters need to be attached to transformer lugs, supporting installations of cutouts, cable terminators, and arresters in single-phase and three-phase configurations on pole or crossarm setups.

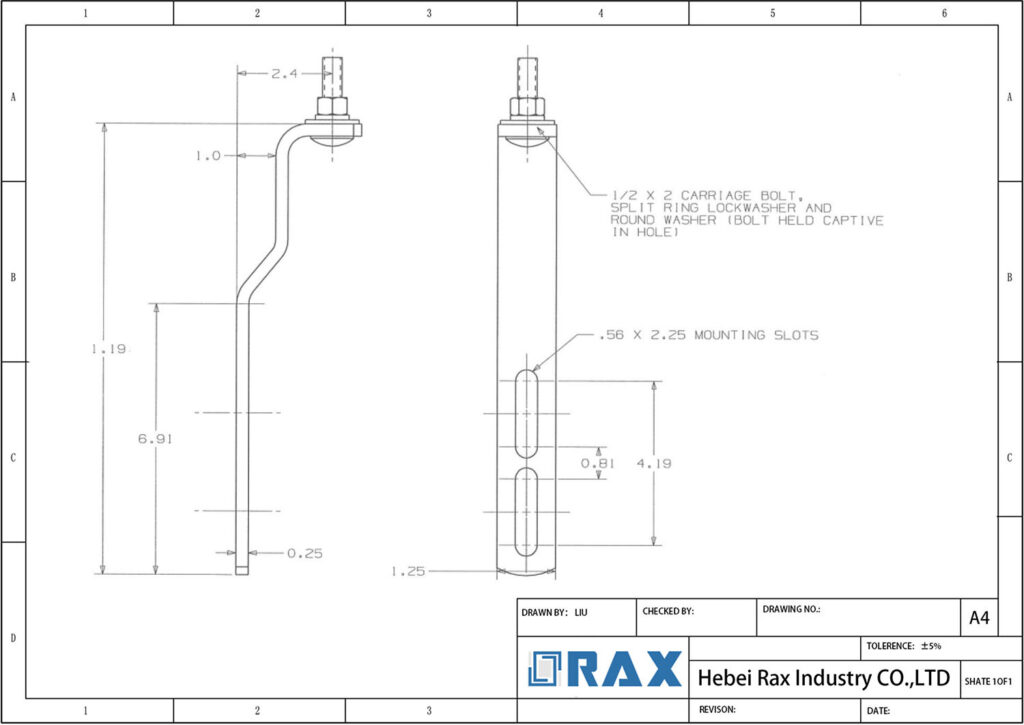

The bracket is constructed from A36 hot rolled steel with a hot dip galvanized finish conforming to American Society for Testing and Materials (ASTM) A-153 standards, providing resistance to corrosion and environmental exposure. Steel dimensions typically measure 1/4 inch by 1-1/4 inches or 1/4 inch by 1-1/2 inches, with overall lengths up to 7-1/2 inches.

Mounting hole configurations include slots measuring 9/16 inch by 1-1/2 inches and hole diameters of 9/16 inch to accommodate different installation requirements. Standard hardware includes a 1/2 inch by 1-1/2 inch or 1/2 inch by 2 inch arrester mounting bolt, hex nuts, split lock washers, and external tooth lockwashers.

Optional equipment mounting hardware features galvanized steel hex head machine bolts, carriage bolts, flat washers, tank lug bolts, and copper ground straps. Catalog numbers include DM59B1 and series designations such as TMSA-10 or TMSA-12, with optional hardware packages indicated by suffixes like “GH” for galvanized components.

Expert Engineering from RaxPower Tank Mounted Arrester Bracket Wholesaler

At RaxPower, we pride ourselves in delivering exceptional products that not only meet but exceed your expectations. Understanding the critical need for safety in storage tank operations, our Tank Mounted Arrester Bracket is engineered to support flame arrestors that effectively prevent the propagation of flames, protecting your storage tanks from potentially disastrous situations.

The bracket attaches securely to tank lugs, constructed from high-quality galvanized steel per ASTM A-153, ensuring durability and corrosion resistance for reliable performance in various industrial environments. This robust design helps maintain the integrity of your safety systems, giving you confidence in your operational measures.

Our commitment to quality is unwavering, backed by over 21 years of manufacturing experience. As a leading manufacturer of pole line hardware, we utilize advanced processes like hot forging to achieve greater strength and precise sizing. Strict quality control, including load testing and galvanization that meets ISO 1461 standards, ensures every bracket offers peace of mind by reducing risks and enhancing safety.

Whether you are expanding your facilities or optimizing current safety measures, partnering with RaxPower guarantees access to durable, high-quality brackets tailored to your needs. Contact us today to learn more about the Tank Mounted Arrester Bracket and how it can elevate your safety protocols.

| Parameter | Value |

|---|---|

| Catalog Number | DM59B1, TMSA-10, TMSA-12 |

| Material | A36 hot rolled steel |

| Finish | Hot dip galvanized per ASTM A-153 |

| Steel Dimensions | 1/4″ x 1-1/4″ or 1/4″ x 1-1/2″ |

| Mounting Hole Dimensions | 9/16″ x 1-1/2″ slots or similar |

| Hardware Included | 1/2″ x 1-1/2″ or 1/2″ x 2″ arrester mounting bolt, hex nuts, split lock washers, external tooth lockwashers; optional galvanized hardware available |

| Weight | 1.22 lb |

| Overall Length | Up to 7-1/2 inches |

| Bolt Diameter | 1/2 inch |

| Standards | ASTM A-153 |

Related Products

Frequently Asked Questions (FAQS)

What is the tank mounted arrester bracket used for?

The tank mounted arrester bracket is designed for mounting surge arresters to overhead distribution transformer and regulator tanks. It attaches to transformer lugs to support and stabilize the arrester during operation.

How can I be confident in the corrosion resistance and longevity of your arrester brackets?

Our tank mounted arrester brackets are made from galvanized steel per ASTM A-153, ensuring excellent corrosion resistance and durability. RaxPower utilizes hot-dip galvanizing with controlled liquid temperature, resulting in smooth, bright surfaces without defects, and a mean coating thickness exceeding 85 microns per ISO 1461 for long-term performance in harsh environments.

What variety of bracket options do you offer to suit different project requirements?

We provide options including single phase and three phase style brackets, available in steel or aluminum construction. Various models are available, such as TMSA-10, TMSA-12, TMSA-15, TMSA-27, and TMSA-34, with dimensions including 1/4 x 1-1/2 and standard lengths of 7-1/2 inches, with different mounting hole sizes to suit specific application needs. RaxPower's comprehensive product range ensures compatibility with diverse systems, supporting projects from utility grids to renewable energy installations.

What installation support is included with your brackets for easy setup?

Each bracket comes with equipment mounting hardware, such as 1/2 x 2 arrester mounting bolts with nut, split lock washer, and external tooth lock washer, as well as tank lug bolts with split lock washers and round washers. The mounting holes are open-sided for easy placement under lug bolt heads, ensuring a secure fit and straightforward installation. RaxPower ensures all necessary components are included, reducing on-site effort and enhancing compatibility with existing systems.

How do you ensure consistent quality and dimensional accuracy across all production batches?

Our brackets are precision-made with accurate sizing, utilizing automatic machines and semi-automatic molds to maintain uniformity. RaxPower implements strict quality control, including raw material selection, multi-stage testing, and reviews before packing, with load tests and gauge tests per IEC 120 standards to guarantee 100% quality and reliability.

Get A Quick Quotation Today