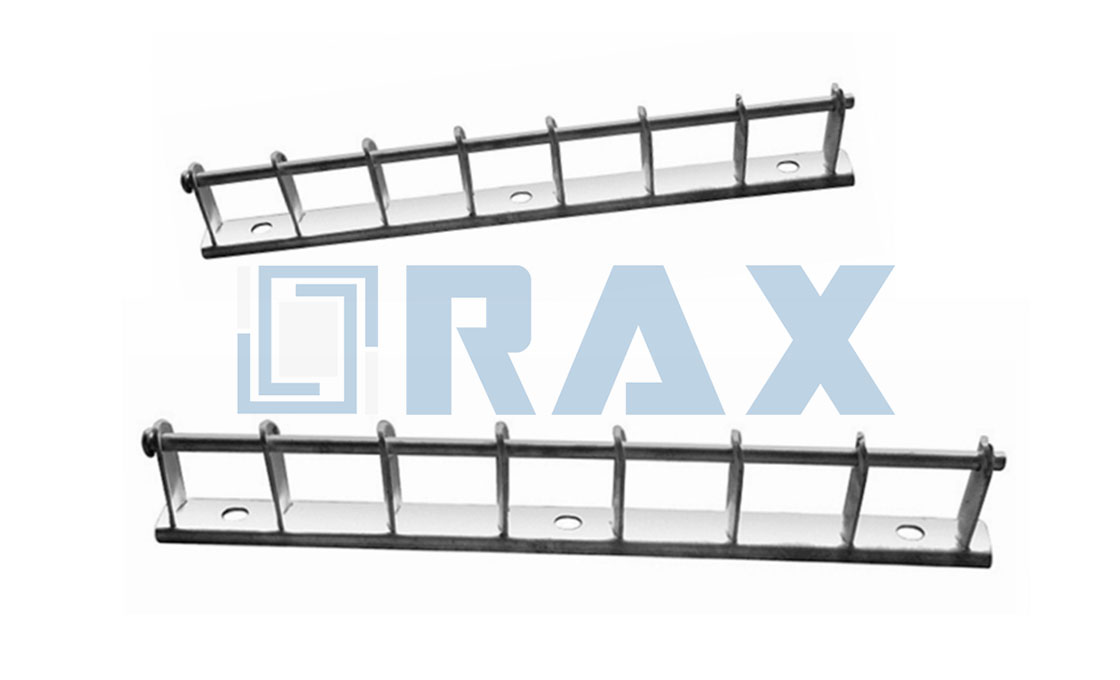

Underground cable racks support and organize cable runs within manholes and vaults, managing electric and communications cables in underground utility environments. These structural components provide secure cable placement and routing through their specialized design features.

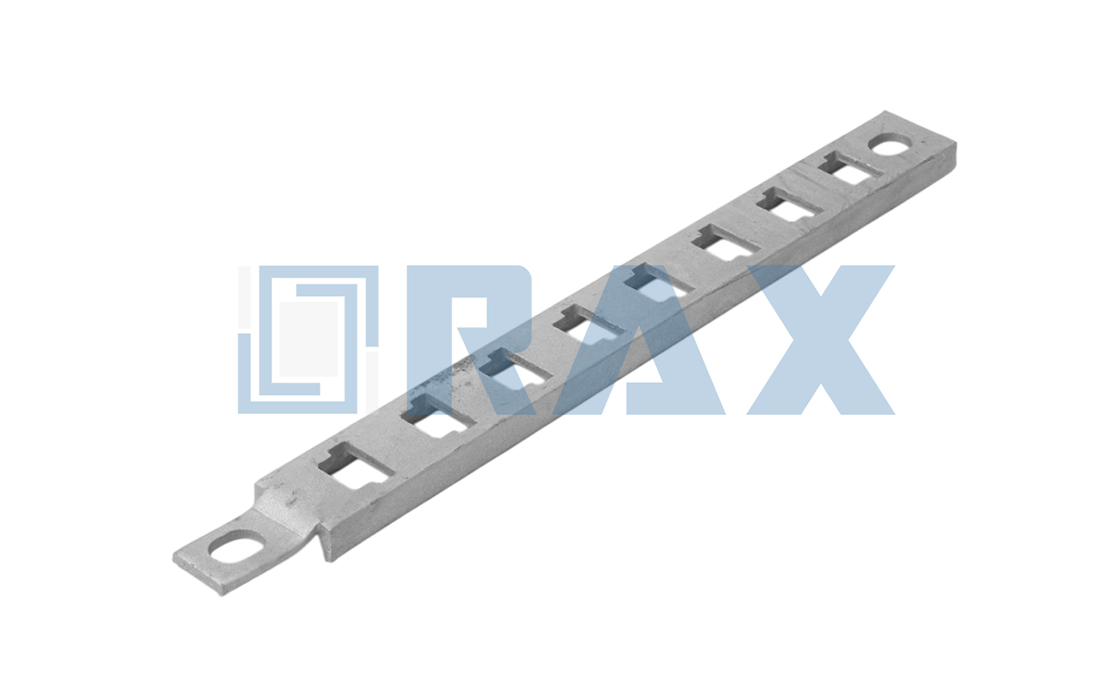

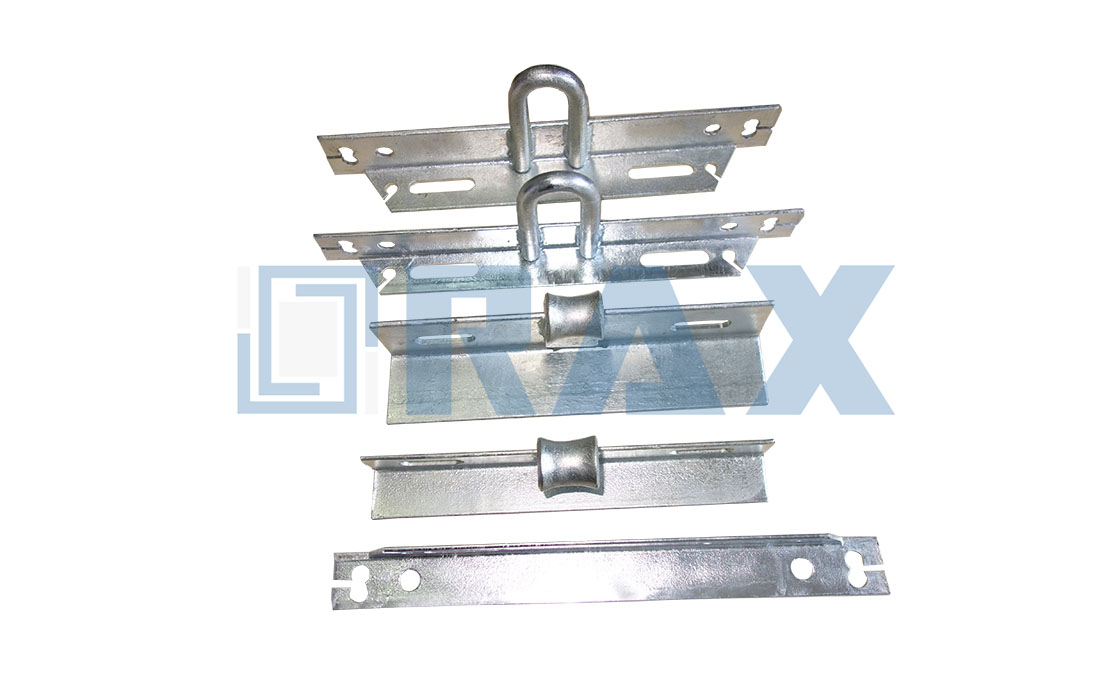

The racks feature T-slots spaced at 1-1/2-inch intervals for attaching cable hooks that lock securely into place. Many models include interlocking mounting slots at each end, enabling multiple racks to combine into a single unit. Hot-rolled steel channel construction (1-1/2 x 9/16 x 3/16 inches) receives hot dip galvanized coating per ASTM A123 or A153 specifications. Nonmetallic versions, molded from UL Listed Glass Reinforced Polymer (GRP), offer non-conductive, dielectric properties with resistance to rust and corrosion while maintaining load capacity comparable to steel racks.

Available lengths range from 15 to 240 inches with hole counts of 8, 14, and 18 options. Mounting hole spacing varies: 13-1/2 inches for 15-inch racks, 22-1/2 inches for 24-inch racks, and 28-1/2 inches for 30-inch racks. Products comply with ANSI C135.35 standards and may be Buy America Qualified, with weights per 100 pieces ranging from 139 to 2420 pounds.

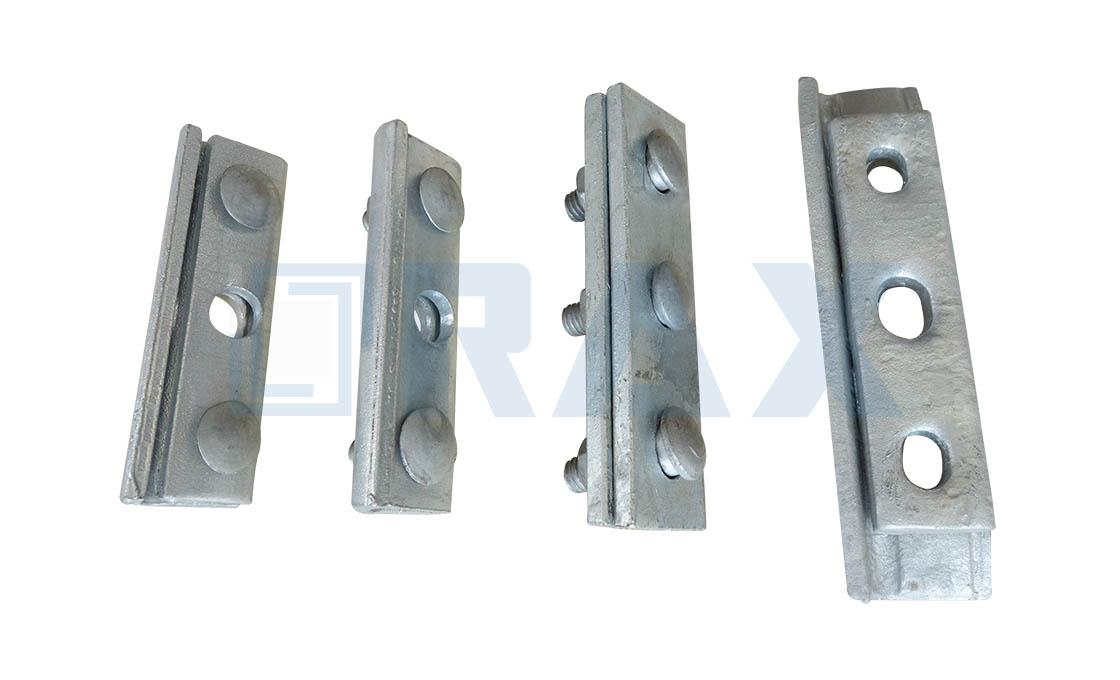

Compatible cable hooks (models J5132A, J5133A, J5134A, U6701, U6702, U6704A) fit into the T-slots, featuring turned-up ends to prevent cable slippage. Hook extensions from the rack face include 7-1/2, 10, and 14-inch options. Installation uses expansion or anchor bolts for wall mounting in underground spaces.

Underground Cable Rack Supplier for Efficient Installation

RaxPower, established in 2003 in Hebei Province, China, with over 21 years of expertise as a specialized manufacturer of pole line hardware, offers high-quality Underground Cable Racks for the construction of electric and communications cables in underground vaults. Our cable rack is functional in any electrical situation, allowing new cables to be positioned directly in the tray instead of pulling them through pipes, which simplifies installation and enhances efficiency.

Utilizing leading materials and advanced manufacturing processes like hot forging and hot-dip galvanizing, we ensure superior strength, durability, and safety, with smooth, bright surfaces that meet ISO 1461 standards for coating thickness. As an ISO9001 certified company, we employ strict quality control, including raw material selection, multi-stage testing, and load tests per IEC 120, with products passing SGS tests for reliability.

Our underground cable racks provide excellent durableness, comply with NEMA standards, and are designed for long operating life in diverse environments, supported by our 17,000 sqm production workshops and skilled team of over 170 employees.

So what are you waiting for? For more inquiries, email us now.

| Parameter | Value |

|---|---|

| Material | Hot-rolled steel channel, Hot dip galvanized per ASTM A123/A153 |

| Channel Dimensions | 1-1/2 x 9/16 x 3/16 inches |

| T-slot Spacing | 1-1/2 inches |

| Mounting Slot Type | Interlocking slots at each end for 8, 14, and 18-hole racks |

| Standards | ASTM A123/A153, ANSI C135.35 |

| Buy America Qualified | Yes |

| Nonmetallic Material | UL Listed Glass Reinforced Polymer |

| Standard Sizes | 15 in length, 8 holes, 13-1/2 in mounting hole spacing, 139 lbs/100 pcs 24 in length, 14 holes, 22-1/2 in mounting hole spacing, 230 lbs/100 pcs 30 in length, 18 holes, 28-1/2 in mounting hole spacing, 290 lbs/100 pcs |

Frequently Asked Questions (FAQS)

What are the primary applications for these cable racks?

They support cable runs in manholes and vaults for electric and communications cables, providing organized and secure cable management in underground environments.

What materials and protective finishes are used?

The racks are manufactured from 1-1/2 x 9/16 x 3/16-inch hot-rolled steel channel and are hot dip galvanized per ISO 1461 for long-term corrosion resistance in critical infrastructure applications.

What sizes and dimensions are available?

Common configurations include 8, 14, and 18-hole racks with overall lengths of 15, 24, and 30 inches. Mounting hole spacing varies by model (e.g., 13-1/2 inches for 15-inch racks), and weights range from approximately 139 to 2420 pounds per 100 pieces.

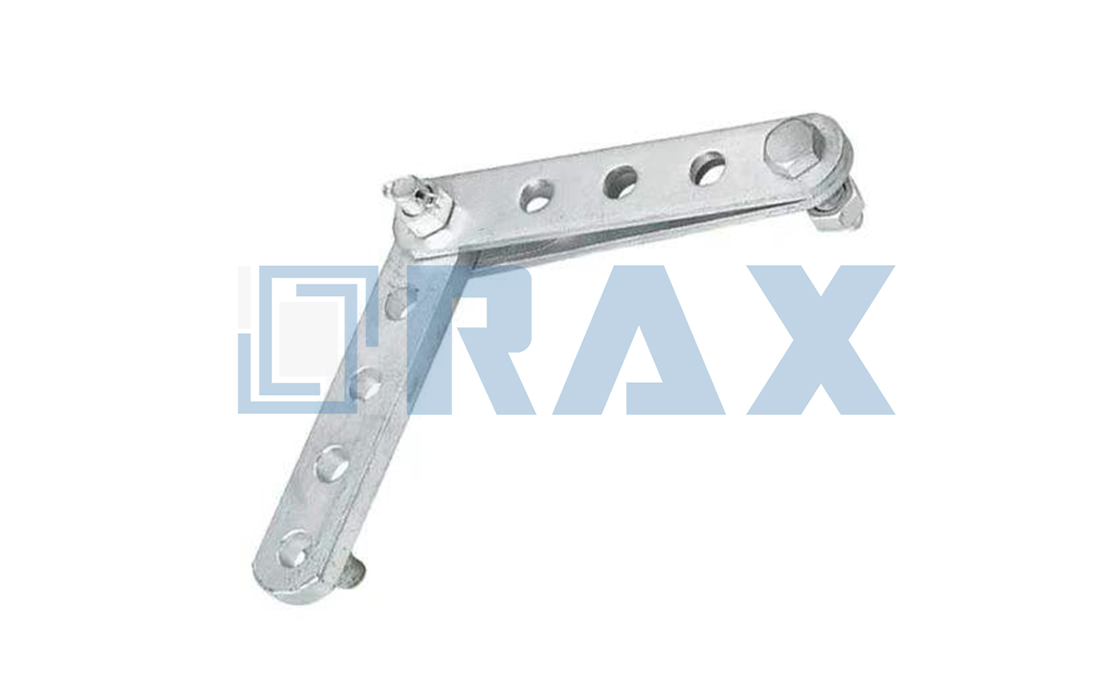

How are the racks mounted and combined?

Racks with mounting slots at each end interlock to create extended support lengths, while longer models mount through T-slots. They fasten to manhole or interior walls using expansion bolts.

Which cable hooks are compatible with these racks?

Compatible hooks include types 10A35 through 10A39, 10C38, 10A60, 10B60, 10A61, and 10B61. These hooks fit into T-slots spaced at 1-1/2-inch intervals and feature turned-up ends to prevent cable or insulator slippage.

What certifications and standards do the racks comply with?

The racks comply with ISO 1461 for galvanizing and may meet ANSI C135.35 standards. Select models are RUS listed, ensuring compliance with utility industry specifications.

Get A Quick Quotation Today