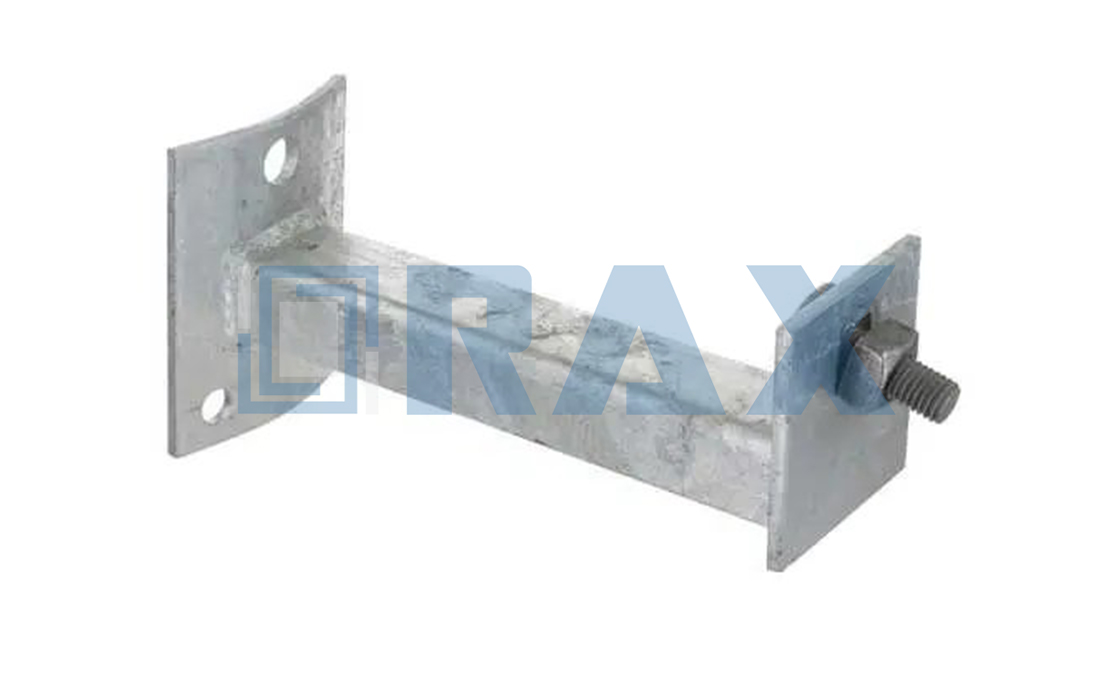

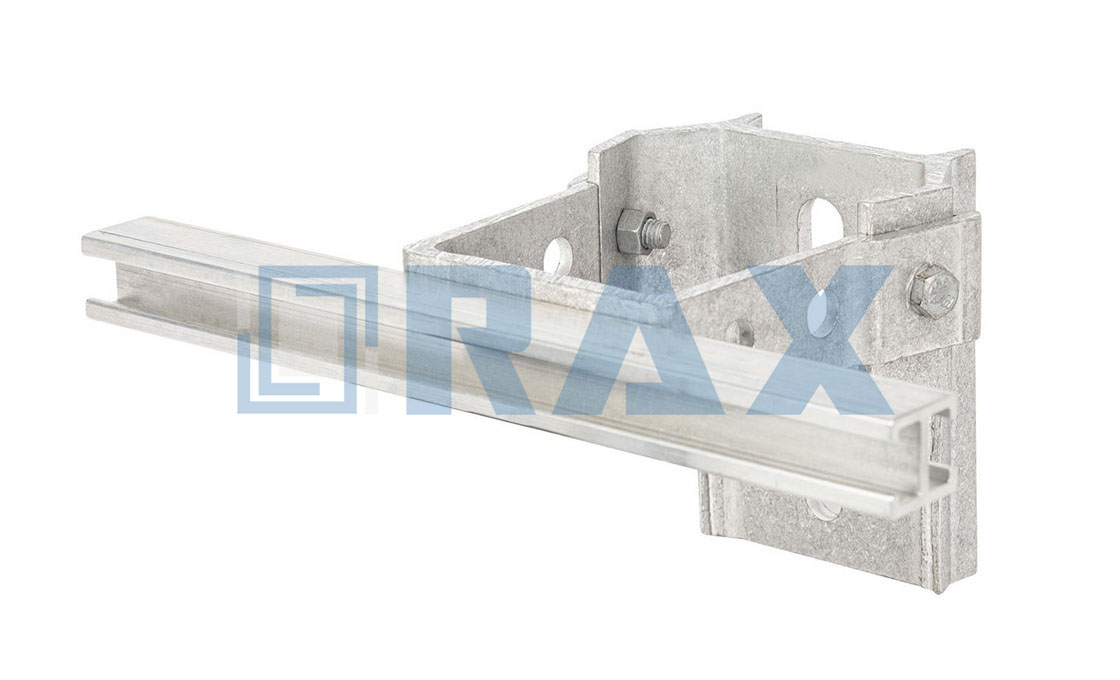

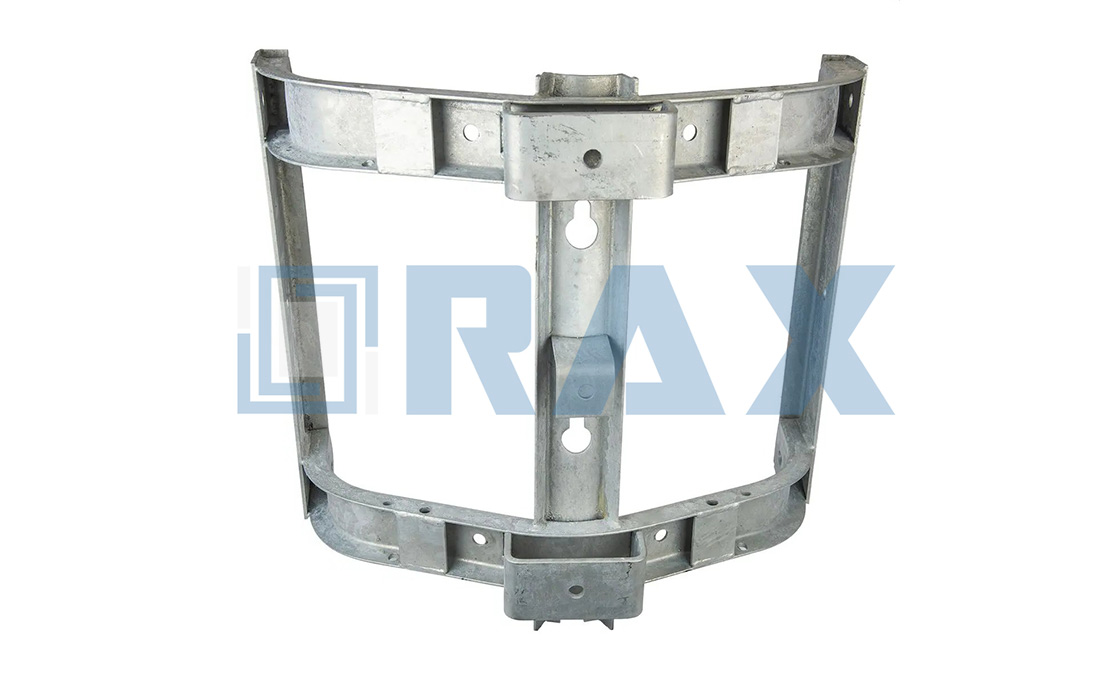

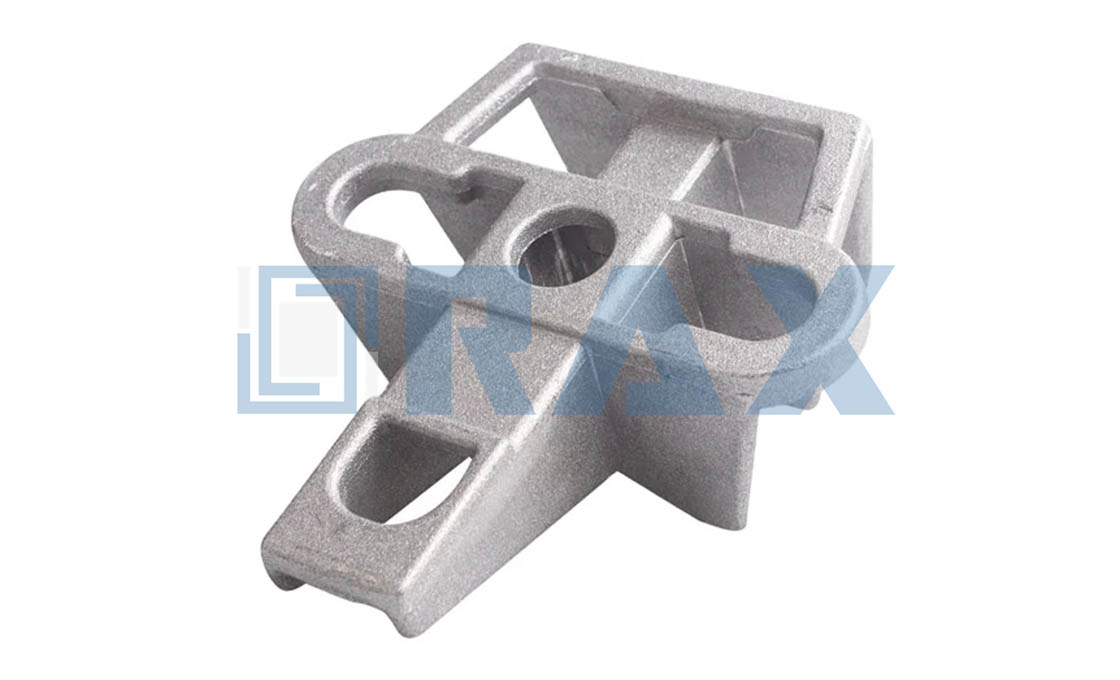

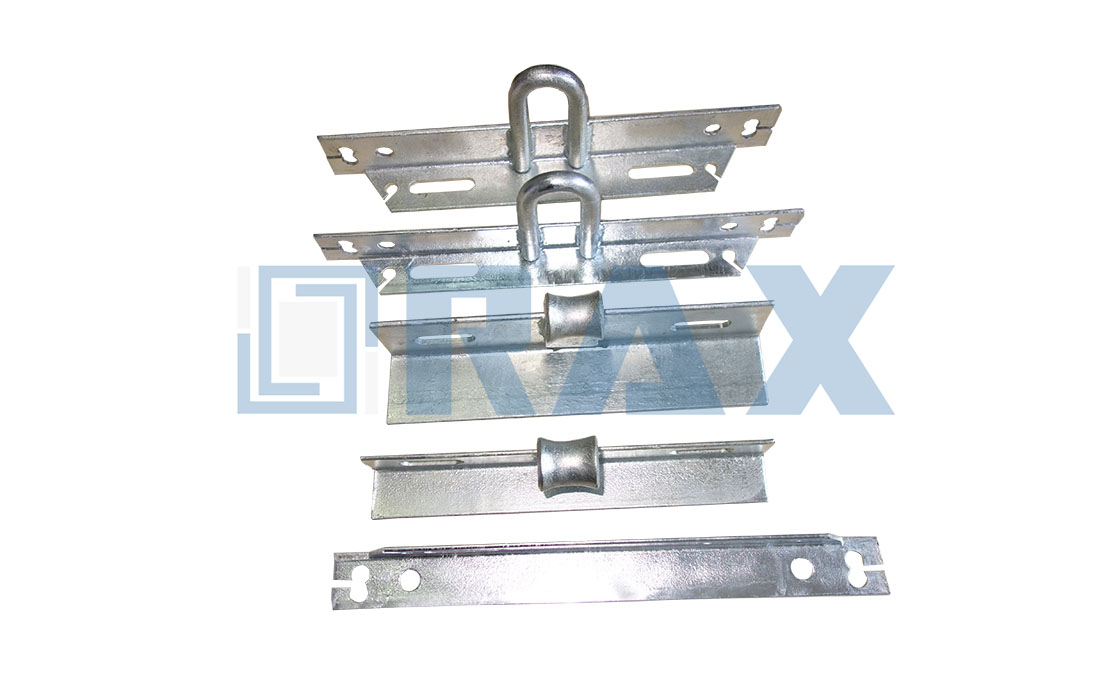

The secondary rack extension bracket mounts to utility poles in pairs to support secondary racks at an offset distance from the pole, typically 6 inches. This offset provides clearance for transformers and other equipment while maintaining proper wire alignment for electrical distribution. The bracket’s curved back, 3 inches wide, fits snugly against the pole surface to maximize bearing area and stability.

Constructed from heavy-duty steel with hot dip galvanizing per American Society for Testing and Materials (ASTM) A153, the bracket resists corrosion, moisture, and chemical exposure in outdoor environments. It meets American National Standards Institute (ANSI) C135.7 specifications and exceeds strength requirements for medium and heavy-duty applications in power distribution infrastructure.

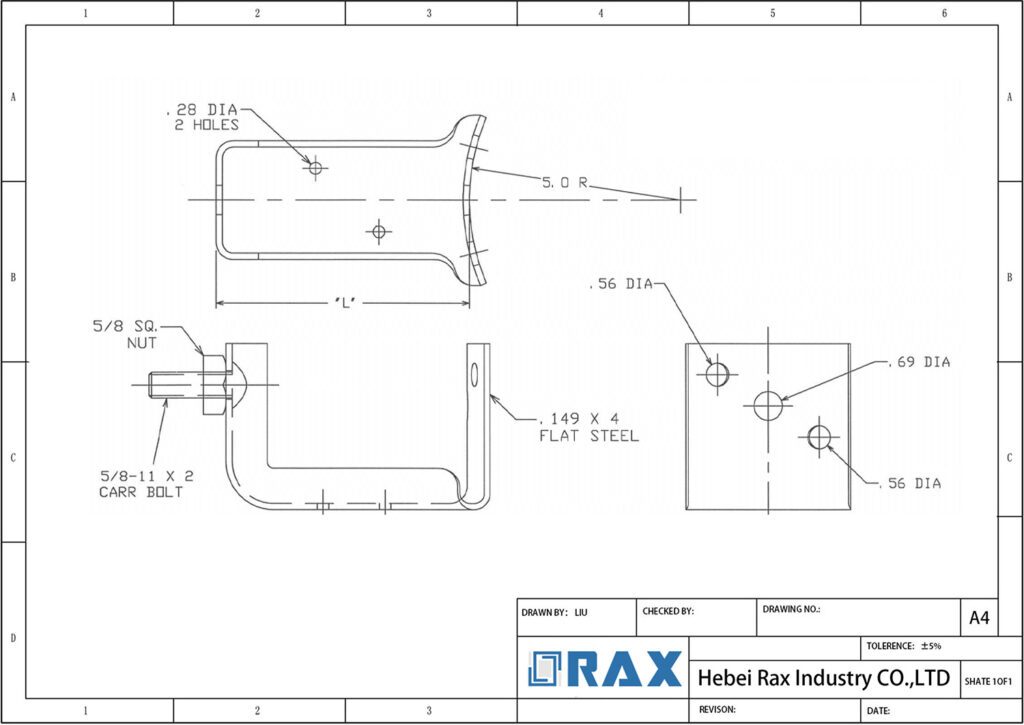

Mounting slots accommodate 5/8″ bolts, with staggered holes allowing alternative installation using 1/2″ lag screws. A groove retains a square nut, enabling installation over existing bolts without disturbing current setups. The bracket typically measures 8 inches long, 3.9 inches wide, and 4 inches high, weighing approximately 2.68 pounds. Standard hardware includes a 5/8″ x 2″ carriage bolt for secure pole attachment.

Reliable Secondary Rack Extension Bracket Supplier

RaxPower is a leading manufacturer of Pole Line Hardware and Fastener in China, established in 2003 and located in Hebei Province. Our Secondary Rack Extension Bracket is designed for mounting secondary racks where obstructions must be overcome, made from hot-dip galvanized steel to ensure corrosion resistance and longevity.

This bracket exceeds strength specifications for both ANSI medium and heavy type racks, featuring smooth, rounded pressed steel struts that prevent insulation damage during conductor stringing. The curved back fits snugly to the pole with a wide bearing surface, enhancing stability and load distribution.

With 21 years of manufacturing expertise, RaxPower employs advanced processes like hot forging for greater strength and accurate sizing, supported by strict quality control from raw material selection to multi-stage testing. Our commitment to Integrity, Profession, and Win-win Cooperation ensures reliable, high-quality products tailored to global standards.

Begin by contacting us for guidance on purchasing the ideal secondary rack for your project.

| Parameter | Value |

|---|---|

| Length | 8 in |

| Width | 3.9 in |

| Height | 4 in |

| Weight | 2.68 lb |

| Material | Heavy-duty steel |

| Coating | Hot dip galvanized per ASTM A153 |

| Industry Standards | ANSI C135.7 |

| Pole Distance (Offset) | 6 in |

| Curved Back Width | 3 in |

| Fastener Size | 5/8″ bolt or 1/2″ lag screw |

| Carriage Bolt Included | 5/8″ x 2″ carriage bolt |

| Quantity per Set | 2 |

Frequently Asked Questions (FAQS)

What is a secondary rack extension bracket used for?

The secondary rack extension bracket provides additional clearance between a secondary rack and the pole surface when necessary to clear obstructions or maintain proper wire alignment. These brackets are fastened to the pole and used in pairs for mounting secondary racks where obstructions require the rack to be offset from the pole.

What material is the bracket made from and how is it finished?

The bracket is made of steel and is hot dip galvanized for corrosion protection, in accordance with ASTM A153 standards.

What are the typical dimensions of the bracket?

Dimensions vary by model, but common sizes include a length of 8 inches to 15 inches, a width of 3.9 inches, and a height of 4 inches, with a curved back that is 3 inches wide. Weight ranges from approximately 2.68 lb to 3.49 lb.

How is the bracket attached to the utility pole?

The bracket is curved to fit the pole and has staggered holes that permit mounting with a 5/8 through bolt or two 1/2 lag screws. A 5/8 x 2 carriage bolt is furnished for fastening the secondary rack to the bracket, and it is secured using nuts and bolts for stable installation.

What industry standards does the bracket comply with?

The bracket complies with ANSI C135.7 for industry requirements and ASTM A153 for galvanization, ensuring it meets rigorous quality and safety standards.

How do you maintain consistent product quality and durability for long-term performance?

We implement strict quality control measures, including raw material selection and multi-stage testing. We conduct load and gauge tests to verify strength and dimensional accuracy, ensuring consistent quality and longevity.

What is your capacity for handling bulk orders and ensuring timely delivery for large-scale projects?

We operate a large warehouse and distribution center, enabling quick and efficient shipments. With extensive production facilities and inventory management, we are equipped to fulfill bulk orders promptly, supporting project timelines and on-time delivery commitments.

Can you accommodate custom specifications or small batch orders for specialized applications?

Yes, we offer OEM and ODM services with no minimum order quantity (MOQ). We can tailor products to meet specific project needs, such as unique dimensions or specialized finishes, providing flexibility for custom solutions across various applications.

Get A Quick Quotation Today