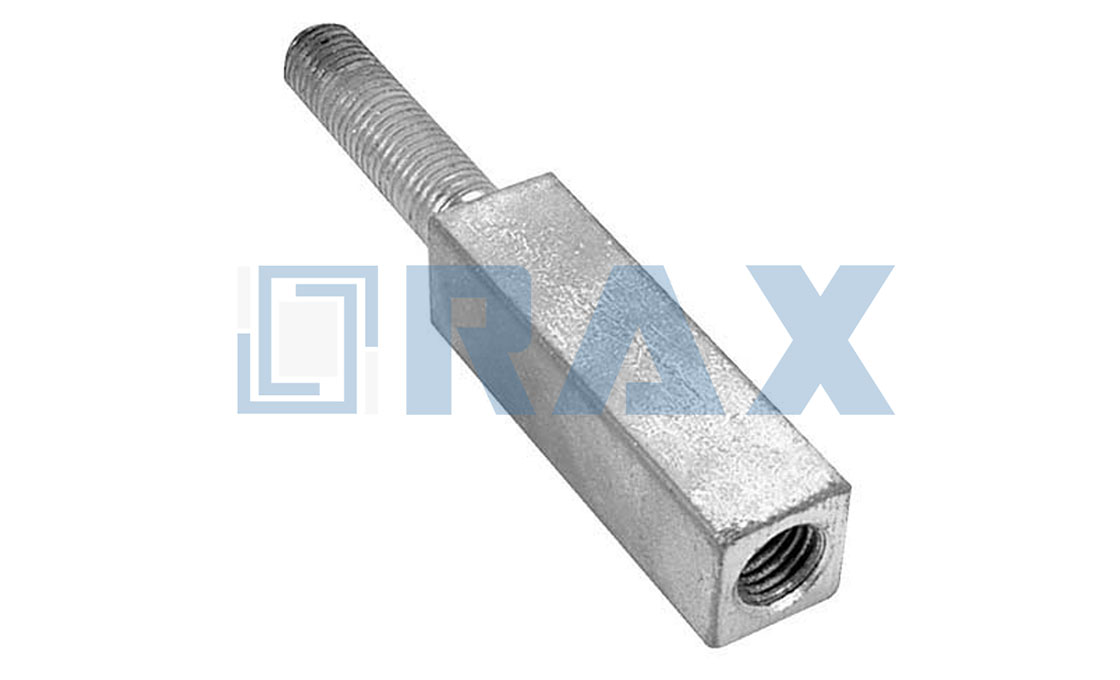

Upset bolts are specialized fasteners that secure spool insulators on utility poles, supporting neutral conductors and secondary service wires. Typically hot-dip galvanized per ASTM A-153 standards, these bolts resist corrosion and provide long-term durability in outdoor electrical distribution systems. They are manufactured through drop forging, where heated metal bars are shaped to create high-tensile-strength bolt heads with precise dimensions.

Two primary variants exist: single upset bolts feature one forged plate at the insulator end, while double upset bolts incorporate two plates, providing additional clearance (1 to 5/8 inches) between the insulator and pole. Both types commonly comply with ANSI C135.31 standards for load and deflection requirements. The assembly includes a forged plate that prevents pin dislodgment, an insulator pin for conductor isolation, a round washer for load distribution, and square nuts with a lock nut to maintain tension under vibration.

Standard specifications include 5/8-inch thread diameter, overall lengths from 10 to 24 inches, and tensile strengths up to 13,550 pounds. Made from carbon or alloy steel, the galvanized coating ensures extended service life in various environmental conditions. Installation involves drilling holes matching the bolt diameter, inserting the bolt through the pole, and securing it with washers and nuts using basic hand tools.

Upset Bolt Wholesaler with 21 Years of Expertise

At RaxPower, we not only supply industry-standard components but also provide tailored solutions to meet your project requirements. Our Upset Bolts are specialized fasteners for spool insulators, featuring hot-formed upset heads for maximum resistance to head failure and conforming to ANSI and NEMA specifications.

With 21 years of expertise, we leverage proprietary manufacturing systems and advanced hot forging technology to deliver full OEM/ODM services, including:

- Customized dimensions and hardware accessories

- Corrosion-resistant surface treatments like hot-dip galvanizing

- Flexible production for both small and large orders

This approach reduces your potential risks and hidden costs by ensuring consistent quality and timely delivery. Our cause-and-effect methodology means that from material selection to structural design, we focus on enhancing durability and performance.

Clients trust us for hassle-free service: “RaxPower thinks ahead, saving us energy,” notes a project manager.

Let’s talk about your next project! Whether you have detailed drawings or just a concept, we’re ready to listen.

| Type | Shank Length (in) | Overall Length (in) | Thread Length (in) | Weight per 100 pieces (lbs) | Diameter (in) | Tensile Strength (lbs) | Material | Finish | Standards |

|---|---|---|---|---|---|---|---|---|---|

| Single Upset | 8 | 12.5 | 4 | 63 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Single Upset | 9 | 13.3 | 4 | 68 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Single Upset | 10 | 14.5 | 4 | 60 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Single Upset | 12 | 16.5 | 6 | 80 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Single Upset | 14 | 18.5 | 6 | 90 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Double Upset | 8 | 14 | 4 | 73 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Double Upset | 9 | 15 | 4 | 77 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Double Upset | 10 | 16 | 4 | 65 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Double Upset | 12 | 18 | 6 | 72 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

| Double Upset | 14 | 20 | 6 | 80 | 5/8 | 13,550 | Carbon Steel | Hot-dip galvanized per ASTM A-153 | ANSI C135.31 |

Frequently Asked Questions (FAQS)

What is an upset bolt?

An upset bolt is a forged fastener designed for spool insulators, assembled on utility poles to support neutral conductors and power wires. Also known as an upset spool bolt or bolt upset, it features forged plates at the insulator end for enhanced strength.

What are the different types of upset bolts?

There are two types: single upset bolts (one forged plate) and double upset bolts (two forged plates at the insulator end).

What are the main applications of upset bolts?

Upset bolts are installed on utility poles to support secondary service wires and neutral conductors, providing secure mounting for insulator pins that carry power lines.

What specifications should I consider when selecting an upset bolt?

Key specifications include diameter (commonly 5/8 inch), tensile strength (e.g., 12400 lbs), material (steel), finish (hot-dip galvanized per ASTM A-153), thread length (typically 6 inches), and compliance with ANSI C135.31 standards, which require supporting loads up to 800 pounds with a deflection angle of 10 degrees.

How is an upset bolt installed?

Drill holes in the pole matching the bolt diameter, insert the bolt through the holes, and secure with nuts and washers using standard tools like spanners or pliers. Installation is straightforward with basic equipment and an assistant.

How can your manufacturing process guarantee consistent product quality for OEM applications?

Our upset bolts are manufactured using automated forging technology for precise sizing and maximum strength. We implement strict quality control with raw material selection and multi-stage testing to ensure every batch meets high consistency standards, protecting your brand integrity.

What is your ordering policy for samples and small quantities?

At RaxPower, we accept orders starting from 1 piece with no minimum quantity requirement. Free samples are available upon request to evaluate quality, fit, and function before committing to larger volumes.

What support do you provide for large projects requiring customized hardware?

We offer flexible production for both small and large orders with full customization according to your designs and specifications. Our efficient manufacturing system ensures stable production, competitive lead times, and timely delivery for bulk projects, supported by professional engineering assistance.

Get A Quick Quotation Today