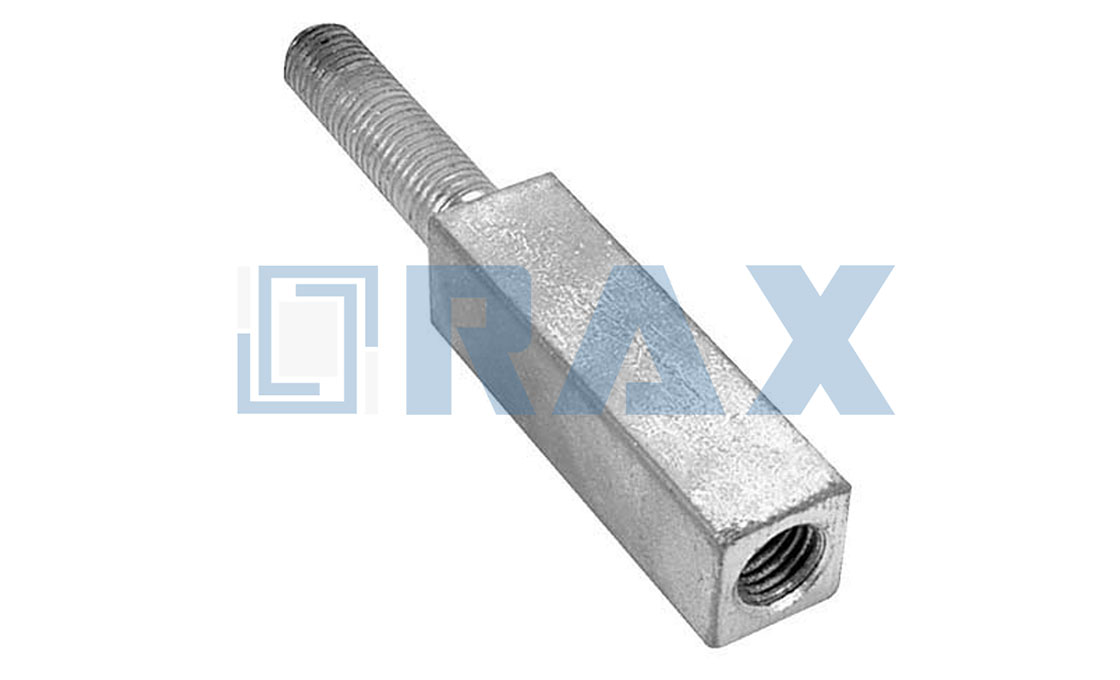

A pigtail bolt features a threaded end and a looped “pigtail” end, enabling secure attachment of cables and components to poles in electrical transmission, distribution, and telecommunications systems. The curved pigtail design provides flexibility for various installation angles while reducing cable tension.

The bolt’s looped end distributes pressure evenly, minimizing deformation and increasing connection stability in complex installations. This design accommodates minor measurement variations and allows use in tight or angled spaces. Installation requires only simple tools—washers fit onto the shaft, the pigtail inserts through pre-drilled holes, and hex nuts tighten to secure the connection.

A complete assembly includes the main body, two hex nuts, and two washers. Common materials include steel with hot-dip galvanizing per ISO 1461 for corrosion resistance. Thread diameters like M16 accommodate different pole types and load requirements. Regional variations exist—some designs feature welded square or round washers on the neck, while others have forged points to prevent washer displacement.

Manufacturing involves cold forging steel wire, threading through cutting or rolling, and forming the pigtail end via twisting. Heat treatment hardens the steel before galvanizing and quality control. Applications include securing cables to poles, hanging dead-end or suspension clamps, and supporting communication lines, signs, and electrical equipment.

Pigtail Bolt Manufacturer

RaxPower, established in 2003 and based in Hebei Province, China, is a well-known manufacturer, supplier, and factory of Pigtail Bolts. As a leading manufacturer of premium, precision-engineered bolts, we specialize in ensuring the secure and reliable attachment of electrical hardware.

Our commitment to quality first and adherence to international standards is demonstrated through strict quality control, including raw material selection and multi-stage testing, ensuring every Pigtail Bolt meets high durability and performance criteria.

These bolts are hot-dip galvanized in compliance with ISO 1461, with a mean coating thickness exceeding 85 microns for superior corrosion resistance.

Advantages such as increased connection stability, enhanced durability, and high adaptability stem from our advanced manufacturing processes, including hot forging and automated machinery, which deliver greater strength and accurate sizing.

Supported by over 21 years of experience and 17,000 square meters of production workshops, RaxPower guarantees consistent quality and on-time delivery for power line applications. Click here, and RaxPower will provide you with free consulting services.

| Thread Diameter | Overall Length (mm) | Eye Diameter (mm) | Weight (kg) | Material | Surface Treatment |

|---|---|---|---|---|---|

| M16 | 210 | 40 | 0.38 | Steel | Hot-dip galvanized per ISO 1461 |

| M16 | 230 | 40 | 0.42 | Steel | Hot-dip galvanized per ISO 1461 |

| M16 | 280 | 40 | 0.62 | Steel | Hot-dip galvanized per ISO 1461 |

| M16 | 400 | 40 | 0.82 | Steel | Hot-dip galvanized per ISO 1461 |

| M16 | 500 | 40 | 1.30 | Steel | Hot-dip galvanized per ISO 1461 |

Frequently Asked Questions (FAQS)

A pigtail bolt is a specialized fastener featuring a threaded end and a looped or pigtail end, also known as a pigtail eye bolt, pigtail hook, pigtail screw, or pigtail fastener. It is essential for secure attachment and support of components in power lines, telecoms, and construction industries.

Pigtail bolts provide increased connection stability, enhanced durability by distributing pressure, high adaptability for tight or angled spaces, improved installation efficiency, and the ability to accommodate minor measurement variations. They offer easy installation with simple tools, immediate support after tightening, and negligible deformation over time, ensuring reliable performance in harsh environments.

Pigtail bolts are commonly used in power line construction for fixing cables to poles or hanging low voltage dead end clamps and suspension clamps, in telecoms to secure communication lines, in construction for signs and banners, in electrical installations to support outdoor equipment, and in mechanical equipment and automotive industries for connecting parts in tight spaces.

The main difference lies in the end design; a pigtail screw hook has a sharp end, whereas a pigtail bolt features a looped or pigtail end. Both are used for similar applications, but the pigtail bolt's design is optimized for secure connections in utility and construction settings.

Pigtail bolts are typically made from high-quality carbon or stainless steel and undergo surface treatments like hot-dip galvanization according to ISO1461 for superior corrosion resistance. This ensures durability and reliability in various weather conditions, with galvanized or stainless steel finishes available to suit different environmental needs.

To install a pigtail bolt, select the appropriate size and type, assemble the washers on the bolt shaft, insert the pigtail hook through a pre-drilled hole while pressing the first washer firmly against the pole, position the second washer on the protruding end, thread two hex nuts clockwise by hand-tightening the first, and finally tighten the nuts with a wrench without overtightening to avoid damage.

Yes, pigtail bolts can be customized in terms of size, thread specifications, material, and design to meet specific project requirements. RaxPower offers tailored solutions, including variations in rod diameter, thread length, and load capacities, ensuring compatibility with different applications such as power line systems, communication towers, and construction projects.

We utilize hot forging and cold forging techniques to achieve high breaking strength and consistent quality while controlling costs. Our automated machines, extensive production facilities, and strict quality supervision—including raw material selection, load testing, gauge tests, and multi-stage testing—ensure reliable performance. Our integrated manufacturing and strategic location near major ports enable efficient handling of large-volume orders with timely shipping and on-time delivery.

We offer competitive wholesale pricing due to our in-house production and economies of scale. Our product range includes a wide variety of sizes, designs, and configurations, with customizable options to meet specific market demands, ensuring good profit margins and product diversity for distributors.

What is a pigtail bolt?

What advantages do pigtail bolts offer?

What are the common applications for pigtail bolts?

How does a pigtail bolt differ from a pigtail screw hook?

What materials and finishes are used in pigtail bolts?

What is the proper installation procedure for a pigtail bolt?

Can pigtail bolts be customized for specific projects?

How do you ensure quality for OEM partnerships and large project orders?

What wholesale pricing and customization options are available for distributors?

Get A Quick Quotation Today