Lip washers are specialized fastening components that provide secure connections and load distribution in electrical utility systems, machinery, and sealing applications. Commonly installed under insulator pin heads or in fastening assemblies, they prevent loosening and create reliable, stick-proof interfaces in industrial and automotive contexts.

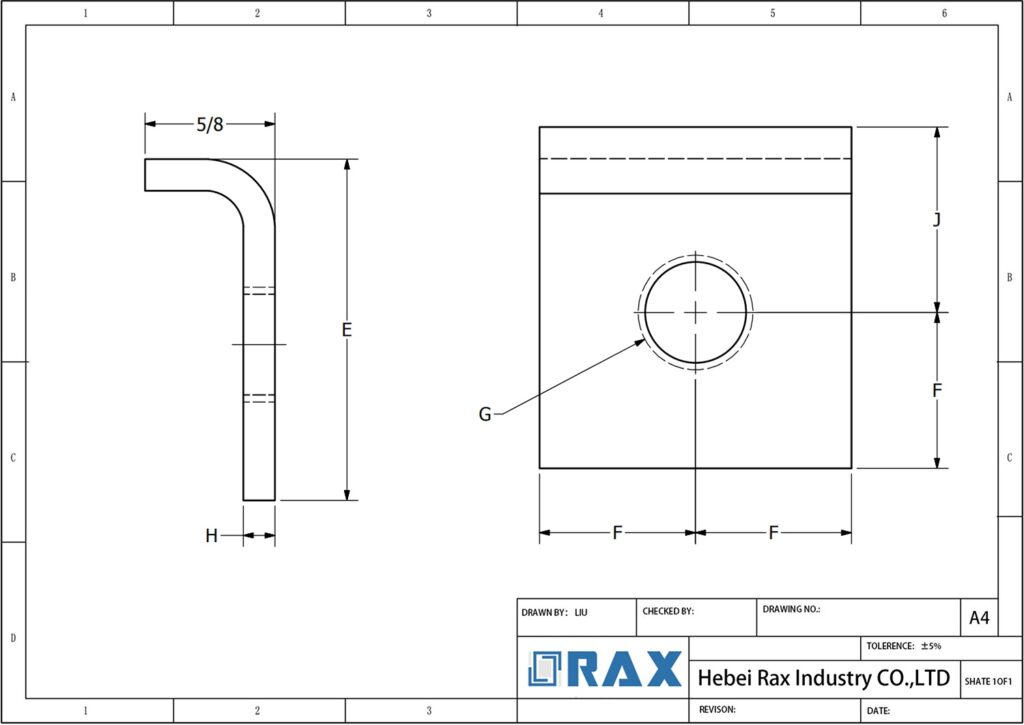

The design features a lip flange enabling wrench tightening for efficient installation and maintenance. Self-retaining variants include anti-loss lips that prevent displacement during assembly or operation. Typical dimensions range up to 2.25 inches in length, 2 inches in width, and 0.1875 inches in thickness, with compatibility for thread sizes like 5/8-11 United National Coarse (UNC) or M12, supporting Original Equipment Manufacturer (OEM) integration across diverse setups.

Material options include galvanized steel, High-Density Polyethylene (PE-HD) plastics, or Polytetrafluoroethylene (PTFE)-based composites. Plastic models operate from -40°C to +70°C, while PTFE variants offer superior chemical resistance against acids, alkalis, and corrosive environments in chemical pipelines and automotive systems. These materials ensure durability under exposure to moisture, oils, abrasion, and mechanical stress.

Galvanization per American Society for Testing and Materials (ASTM) A-153 provides corrosion protection, while compliance with Restriction of Hazardous Substances (RoHS) standards and Buy America(n) qualification ensures environmental safety and domestic sourcing requirements. Technical documentation and manufacturer part numbers facilitate integration and verify conformity with industry regulations.

Lip Washer Manufacturer

The development of bespoke products for our customers benefits from our comprehensive expertise. Lip Washers are used under the head of insulator pins when a stick-proof connection is required. As a technology innovator in high-performance seals, RaxPower specializes in Metal Bonded Rubber Parts. With our professional R&D teams and engineers, we offer a full service.

We process materials such as EPDM, silicone, PTFE, and NBR, with compliance to UL, FDA, and ROHS standards. Our manufacturing processes include hot forging for greater strength and accurate sizing, using automatic machines for uniform products.

Advantages

- With our commitment to quality, every Lip Washer meets rigorous performance standards.

- We employ strict quality control, with multi-stage testing and reviews before packing.

- Products have passed SGS tests and other authoritative research.

FAQ

- What materials do you use? We use selected imported raw materials for durability.

- What processes? We have various molding and forging techniques.

Our philosophy: Design creates wealth, innovation realizes value, science and technology promotes Rubber Bonded Washer, integrity makes brand bright.

Hope to have the opportunity to use our rich experience and good after-sales service to make a contribution to your company’s high quality, high yield and low cost.

| Parameter | Value |

|---|---|

| Material | Galvanized Steel, PE-HD, PTFE-based composites |

| Coating | Galvanized, ASTM A-153 |

| Length | Up to 2.25 in |

| Width | 2.00 in |

| Thickness | 0.1875 in |

| Weight | 0.26 lb |

| Thread Size | 5/8-11UNC |

| Temperature Range | -40°C to +70°C |

| Chemical Resistance | Excellent for harsh environments (PTFE variants) |

| Certifications | ASTM A-153, RoHS, Buy America(n) Qualified |

| RoHS Compliance | Yes |

Frequently Asked Questions (FAQS)

What is a lip washer and what is it used for?

Lip washers are fasteners used under the head of insulator pins when a stick-proof connection is required, making them ideal for pole line construction in electric utility and telecommunications infrastructure.

What material and corrosion protection do RaxPower lip washers have?

RaxPower lip washers are made of steel and hot-dip galvanized per ISO 1461, ensuring a mean coating thickness of more than 85 microns for superior corrosion resistance and long-term reliability in harsh environments.

What are the standard dimensions and weight?

Standard dimensions are 2.250 in x 2.000 in x 0.875 in with a weight of 0.26 lb, ensuring consistency and compatibility with industry requirements.

How are lip washers installed?

The lip flange design allows for wrench tightening with a tapped hole (such as 5/8-11UNC for a 5/8 inch bolt), enabling secure and straightforward installation for efficient field operations.

Do RaxPower lip washers meet regulatory compliance standards?

Yes, they may have certifications like Buy America(n) Qualified, with EU RoHS Indicator No.

Are different models available for specific applications?

Yes, lip washers are designed for various applications, including specific models such as those for the 83811, and are used in valve accessories or pole line construction fasteners.

What are the shipping options?

Orders placed before 2PM EST typically ship the same day, with shipping calculated at checkout.

Get A Quick Quotation Today