Suspension insulators support conductors on high-voltage transmission towers while electrically isolating them from the structure. They comprise insulating discs connected by metal links, forming flexible strings configurable for different voltage requirements and environmental conditions. Types include cap and pin designs and interlink (Hewlett type), available in glass, porcelain, and polymer materials, with specialized variants like fog type for contaminated areas and aerodynamic profiles for high-wind or polluted environments.

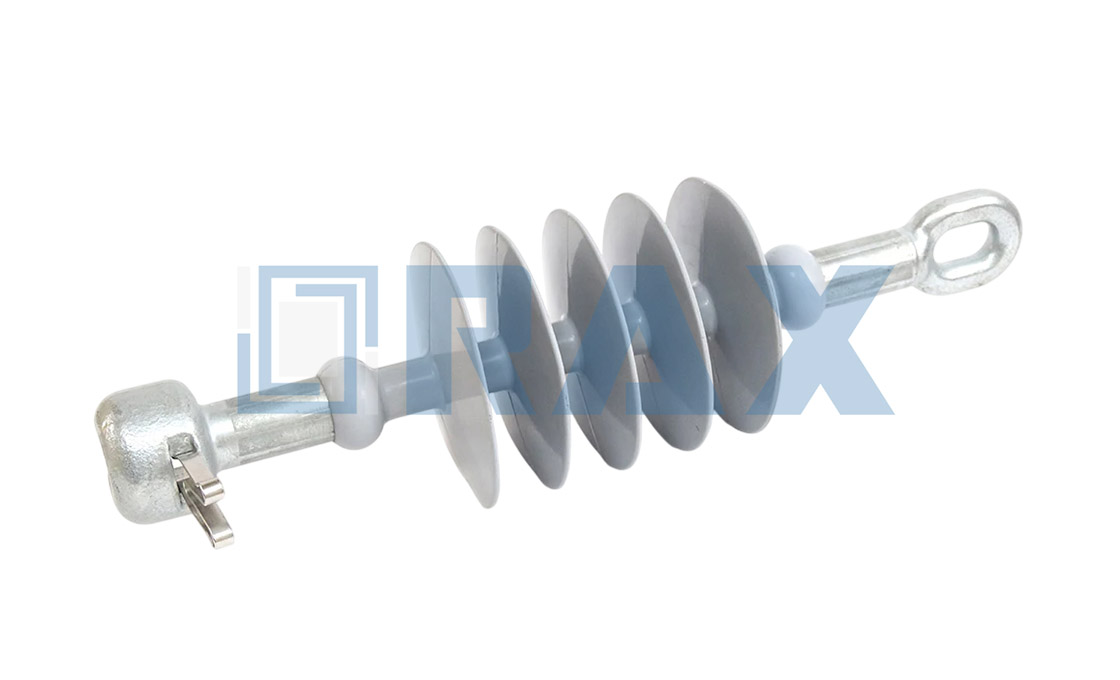

Polymer suspension insulators feature silicone rubber housings bonded to fiberglass core rods, while porcelain and glass types use ceramic or toughened glass dielectric elements. End fittings utilize ductile iron or galvanized steel for corrosion resistance. Multi-layer sealing systems create water-tight barriers, stacked shed designs minimize electrical stress aging, and corona rings protect cores from flashover events.

These insulators distribute electrical stress across multiple discs in series, with design features managing capacitance variations for even voltage distribution. The chain-like structure absorbs mechanical stresses from wind and movement, preventing transmission line or tower damage. Individual failed units can be replaced without disassembling entire strings, simplifying maintenance.

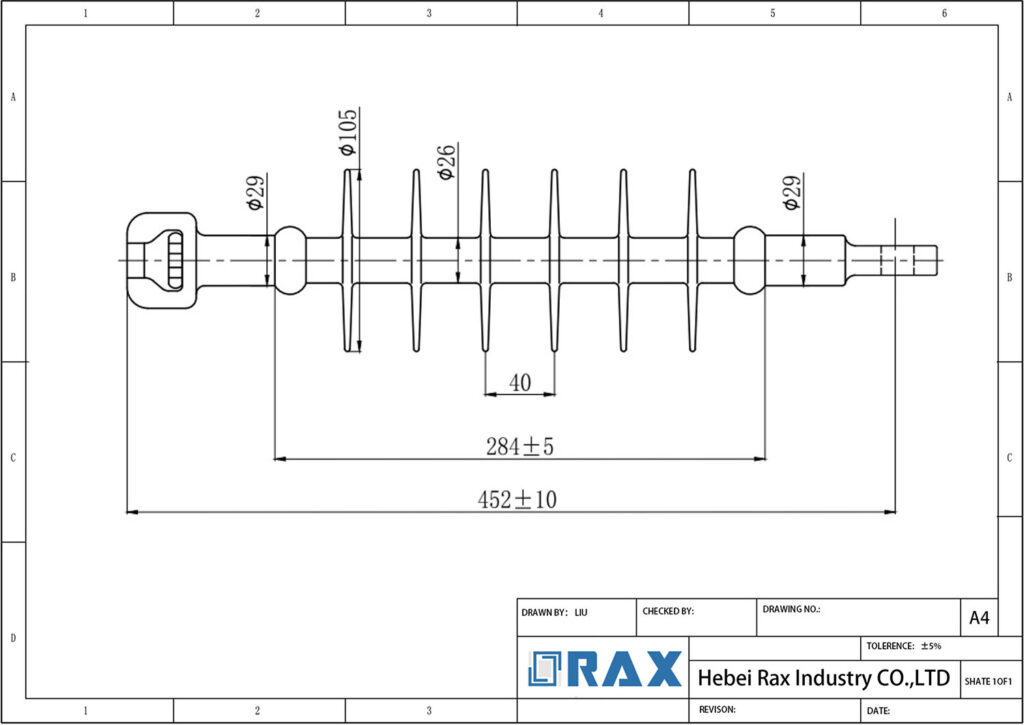

Applications span 69 kV to over 1000 kV transmission lines, substations, and railway electrification across diverse climates. Specifications include mechanical failing loads up to 530 kN, voltage ratings from 11 kV to 230 kV and beyond, and creepage distances exceeding 5000 mm, with shed diameters typically 255-280 mm and adjustable effective lengths.

Enhance Power Transmission with RaxPower Suspension Insulators

Overview

RaxPower is producing top-notch suspension insulators that satisfy your needs and demands at affordable prices. As a leading manufacturer with over 21 years of experience, we specialize in suspension insulators that are essential for the efficient and safe operation of power transmission systems. Our insulators support overhead lines, providing mechanical strength and electrical isolation to prevent power losses and ensure reliability.

Features

Crafted from premium materials, our suspension insulators offer superior durability and performance. They are designed to withstand extreme mechanical loads, resist corrosion, and maintain excellent insulation even in challenging environments.

Rigorously tested to meet IEC standards, our products feature:

- anti-pollution designs

- hydrophobic surfaces

- high shock resistance

Lightweight and easy to install, they reduce maintenance costs and enhance operational efficiency. With a focus on quality and innovation, we provide various types and custom solutions to fit diverse application requirements. Our global supply chain ensures timely delivery to customers worldwide.

Contact us for more information and to place your order NOW!

| Parameter | Value |

|---|---|

| General | |

| Material | Silicone Rubber |

| Material – End Fitting | Ductile Iron |

| Number of Sheds | 76 |

| Shed Style | Uniform |

| Voltage Rating | 230 kV |

| Dimensions | |

| Diameter – Shed(s) | 74 mm |

| Length – Effective | 2382 mm |

| Rod Diameter | 16 mm |

| Thickness – Housing | > 3 mm |

| Electrical Ratings | |

| Creep and Leakage Distance | 5309 mm |

| Critical Impulse Flashover (CIFO) – Negative | 1180 kV |

| Critical Impulse Flashover (CIFO) – Positive | 1165 kV |

| Flashover Voltage – 60 Hz Dry | 805 kV |

| Flashover Voltage – 60 Hz Wet | 735 kV |

| Withstand Voltage – 60 Hz Wet | 510 kV |

| Withstand Voltage – Lightning Impulse (Negative) | 1335 kV |

| Withstand Voltage – Lightning Impulse (Positive) | 1315 kV |

| Arc Distance – Dry | 2083 mm |

| Force Related | |

| Strength Rating – Ultimate | 133 kN |

| Tensile Strength | 133 kN |

| Tensile Strength – Routine | 67 kN |

Frequently Asked Questions (FAQS)

What is a suspension insulator and how is it used in power transmission?

Suspension insulators support transmission lines on steel towers, isolating the lines from the tower. They are used in configurations of two or more based on transmission voltage and environment, and are commonly found in overhead power transmission lines, generators, transformers, railway lines, and electric motors. RaxPower suspension insulators are designed for reliable performance in electrical power transmission systems, particularly in high pollution areas, coastal regions, and industrial zones.

What are the advantages of polymer suspension insulators?

Polymer suspension insulators from RaxPower offer lighter weight, easier installation, high corrosion resistance, excellent hydrophobicity, and reduced maintenance compared to traditional porcelain or glass insulators. They feature anti-pollution design, shock resistance, and are less brittle, ensuring enhanced performance and durability in extreme and challenging environmental conditions.

What materials and construction are used in RaxPower suspension insulators?

RaxPower suspension insulators are constructed with premium materials: silicone rubber housing, electrical grade corrosion-resistant direct draw fiberglass rod, and ductile iron or galvanized steel end fittings. The design includes stacked shed configurations and stress mitigation features to ensure durability, long-lasting performance, and excellent electrical insulation properties.

What are the electrical and mechanical ratings of your suspension insulators?

RaxPower suspension insulators are available for voltage ratings from 69kV to 161kV standard applications, with custom options up to 230kV and higher. Electrical ratings include flashover voltages (60 Hz dry up to 805 kV, wet up to 735 kV) and critical impulse flashover voltages. Mechanical strength ranges from 25,000 lbs to 30,000 lbs ultimate tensile strength, with routine proof test loads from 12,500 lbs to 15,000 lbs.

What standards, certifications, and quality assurance do your products meet?

RaxPower suspension insulators comply with international standards including IEC and ANSI, with certifications such as ISO and CE. We employ strict quality control with raw material selection, multi-stage testing, and dual pre-packing reviews ensuring 100% quality. All products undergo rigorous electrical and mechanical performance testing, including routine proof tests, aging tests, and SGS verification for lab-tested and field-proven reliability.

Can you customize suspension insulators and what is your lead time?

Yes, RaxPower offers OEM services and custom suspension insulators tailored to your specific mechanical load, voltage rating, creepage distance, and environmental requirements based on your drawings. Standard models are in stock for immediate shipment, while large or customized orders typically deliver within approximately 15 days through our efficient production processes and extensive warehousing facilities.

Do you provide samples for quality verification?

Yes, RaxPower provides free samples for evaluation. Please contact our team to learn more about our sample policy and request process for your quality assurance needs.

Get A Quick Quotation Today