The Triangular Yoke Plate links double and multiple insulator strings in parallel assembly for overhead power transmission and communication networks. It connects clevises, socket tongues, and insulators while maintaining spacing between bundled conductors. In suspension applications, it bundles two conductors with a single string insulator; in deadend applications, it joins two insulator strings with one deadend clamp.

Manufactured from forged steel, ductile iron, or galvanized steel, the plate features hot-dip galvanizing per ASTM A153 or ASTM A123 standards. This coating provides corrosion resistance against moisture, salt, and pollution while ensuring a smooth, burr-free surface that minimizes wear on connected components.

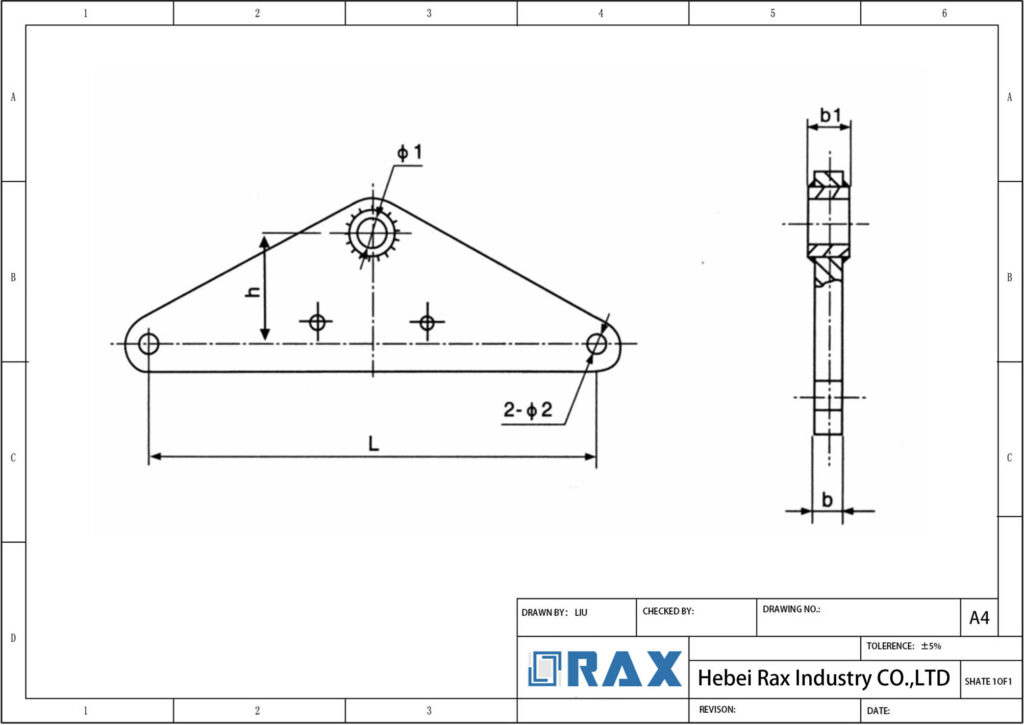

The triangular design includes three standard holes with spacings from 13 to 18 inches and thicknesses from 0.75 to over 1 inch. Variations include rectangular configurations and alternative hole patterns. Manufacturing employs oxy-arc cutting for smooth edges and precision punching for accurate hole placement, with hole diameters typically 1 inch.

Ultimate strength ratings range from 30,000 to 80,000 pounds, with failure loads spanning 70 kN to 600 kN depending on model specifications. These mechanical properties enable reliable load bearing in varied transmission line configurations and environmental conditions.

Triangular Yoke Plate Wholesaler – Trusted in Utility Applications

At RaxPower, we not only supply industry-standard components but also provide tailored solutions to meet your project requirements. Our Triangular Yoke Plate is designed for power and utility needs, used to bundle conductors in suspension applications with a single string insulator or in deadend applications with multiple insulators. It serves to hold conductors steady, balance load, and distribute mechanical forces, ensuring a reliable and firm grip.

Fabricated from high-grade steel, our yoke plates utilize hot forging technology for greater strength and accurate sizing. The manufacturing process includes automatic machines for uniform sizing and precise hole punching. Each plate undergoes hot-dip galvanization with a mean coating thickness exceeding 85 microns, providing robust protection against corrosion and environmental stressors.

We leverage our efficient manufacturing system and strict quality control, including raw material selection and multi-stage testing such as load tests and gauge tests per IEC 120, to reduce potential risks and hidden costs. This customer-centric approach emphasizes quality, risk control, and customization, supporting both small and large orders with timely delivery.

Let’s talk about your next project! We offer customized solutions, free samples, and design support to meet your specific needs.

| Parameter | Value |

|---|---|

| Shape | Triangular |

| Type | Yoke Plate |

| Material | Forged steel, ductile iron, or galvanized steel |

| Finish | Hot-dip galvanizing |

| Galvanizing Standard | ASTM A153 or ASTM A123 |

| Ultimate Strength | 30,000 to 80,000 pounds |

| Failure Load | 70 to 600 kN |

| Hole Spacing | 13 to 18 inches |

| Hole Diameter | Approximately 1 inch |

| Number of Holes | 3 |

| Thickness | 0.75 to over 1 inch |

| Weight | 0.4 to 56 pounds (varies by model) |

Frequently Asked Questions (FAQS)

What is a triangular yoke plate and what is its primary function?

A triangular yoke plate is a connection fitting used for the parallel assembly of double insulator strings and multiple insulator strings in transmission line systems. Its primary function is to maintain the distance between bundled conductors at insulator strings and to join eye-ended parts by compression lugs, facilitating load distribution in suspension and deadend applications.

What materials and protective coatings are used in triangular yoke plates?

Triangular yoke plates are typically made from high-grade steel or ductile iron with a hot-dip galvanized finish. The zinc coating provides corrosion resistance against high humidity, salt exposure, pollution, dust, and solar radiation, ensuring long-term structural integrity and reduced maintenance needs in harsh environments.

What are the common applications for triangular yoke plates?

Triangular yoke plates are commonly used in transmission line systems and communication systems for bundling conductors in suspension applications with a single string insulator, as well as in deadend applications with two strings of insulators and one deadend clamp.

What key technical specifications should I consider when selecting a triangular yoke plate?

Key specifications include ultimate strength (ranging from 30,000 to 80,000 lbs or equivalent in kN), hole spacing (e.g., 13 to 18 inches), thickness (e.g., 0.75 to 1.125 inches), hole diameter (e.g., 1 inch for apex and base holes), material type, and weight. Standard configurations typically feature three holes with variations in dimensions like height (H), length (L), and widths (b, b1). Catalog numbers indicate specific variations tailored to different load and application requirements.

How is mechanical strength tested and ensured?

Mechanical strength is ensured through rigorous quality control testing, including verification of ultimate failure load ratings. Manufacturing processes like oxy-arc cutting and precision punching ensure smooth surfaces and uniform hole alignment for reliable performance under high mechanical loads.

Do you provide third-party certifications for your triangular yoke plates?

Yes, RaxPower can provide type test reports and third-party certifications upon request, ensuring compliance with standards such as IEC, IEEE, or national grid requirements.

What is your typical production lead time?

Lead time varies based on part complexity and order volume. For prototypes or low-volume runs, we typically achieve lead times of 5-7 working days, and rush orders can be accommodated when necessary.

What is your minimum order quantity, and do you handle both small and large orders?

We welcome orders of all sizes with a minimum order quantity of just 1 piece. Our flexible production system efficiently manages both small sample requests and large-scale customized orders.

Can you customize triangular yoke plates to meet specific project requirements?

Absolutely. RaxPower offers comprehensive ODM/OEM services. You can share your application needs, and we will customize the yoke plates accordingly, including material selection, design adjustments, and dimensional specifications.

Get A Quick Quotation Today