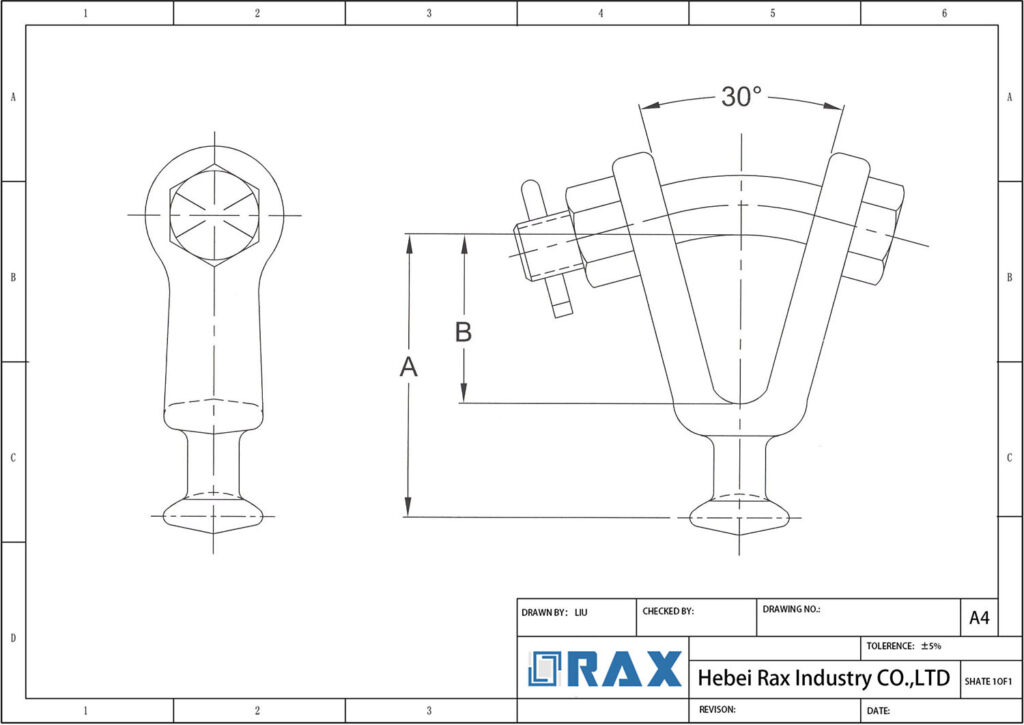

A ball clevis (also called a clevis eye) connects socket insulators or socket tongues via a ball head in electrical transmission and distribution systems. The fitting enables secure attachments between insulators and tower elements in overhead line installations. Ball clevises are classified by structural shape: Y clevis (Y-shaped design) and U clevis (U-shaped configuration), with variations accommodating different connection needs and load conditions.

The main components include a ball head at one end and two holes for inserting a steel pin or hex bolt, creating space to connect other hardware. A cotter pin made of stainless steel provides retention in some designs, ensuring the assembly remains intact under operational stresses. The steel pin or hex bolt secures the clevis during operation.

Manufacturing processes depend on required tension strength. Low-tension applications use casting, while high-strength requirements exceeding 45 kN employ drop forging for enhanced durability and load capacity. Hot dip galvanizing per ISO 1461 standards provides corrosion resistance. Breaking loads range from 70 kN to 160 kN based on transmission line voltages, with standard dimensions including 0.813-inch clevis opening and 0.625-inch pin diameter.

Ball clevises connect ball and socket insulators in overhead transmission lines and pole line hardware installations, supporting utility pole assembly across distribution to high-voltage systems. They are compatible with insulator classes such as ANSI 52-3 and 52-5, ensuring electrical network integrity across various voltage levels.

Ball Clevis Manufacturer – Premium Pole Line Hardware

RaxPower, established in 2003 in Hebei Province, China, is a leading manufacturer of pole line hardware with over 21 years of experience. Our Ball Clevis products are meticulously designed and crafted to meet the highest quality standards, ensuring reliable performance and durability. Utilizing advanced hot forging technology—our most sophisticated process—we produce clevis balls with greater strength and precise sizing. Made from high-quality carbon steel and hot-dip galvanized, they offer excellent corrosion resistance and a tension strength exceeding 45 kN.

We offer a comprehensive range in various sizes and designs, including U-type and Y-type, suitable for applications in power transmission, construction, and utility pole installations.

The key features of our Ball Clevis products include:

- High mechanical properties from quality steel forging

- Hot-dip galvanized for long service life and corrosion resistance

- Rigorous testing, including load tests and gauge checks per international standards

Guided by our ‘customer first’ philosophy, we persist in independent R&D and innovation. Our strict quality control ensures 100% product reliability. Contact us today to learn more about our Ball Clevis products and how they can benefit your business.

| Parameter | Specification |

|---|---|

| Product Type | Ball Clevis (Y Type, U Type) |

| Breaking Load | 70 kN, 120 kN, 160 kN |

| Material | Body: Galvanized Steel, Pin: Galvanized Steel, Cotter Pin: Stainless Steel |

| Clevis Opening | 0.813 inches |

| Pin Diameter | 0.625 inches |

| Manufacturing Process | Casting (for low tension strength), Drop Forging (for high strength >45 kN) |

| Surface Treatment | Hot dip galvanized per ISO 1461 |

| Insulator Compatibility | ANSI 52-3, 52-5 |

| Weight | 1.235 lb |

Frequently Asked Questions (FAQS)

What is a ball clevis and what is its primary function?

RaxPower ball clevis is a type of string hardware that connects the socket insulator or socket tongue by the ball head, used in transmission and distribution lines for secure attachments.

What types of ball clevis are available?

Ball clevis comes in various types, including Y clevis, U clevis, and insulator ball clevis, designed for different pole line and transmission applications.

What materials, finishes, and manufacturing processes are used in your ball clevis products?

RaxPower ball clevis is made from galvanized steel or ductile iron, with hot-dip galvanized finish according to ISO 1461 for corrosion resistance. We use casting for low tension applications and drop forging for high strength requirements over 45kN, ensuring dense material and superior mechanical properties.

What is the breaking load capacity of your ball clevis?

The breaking load varies by transmission line voltage, with common ratings of 70kN, 120kN, and 160kN to meet different strength requirements.

Are your products tested and certified to meet international standards?

Yes, our ball clevises conform to international standards such as IEC, ANSI, and BS. They undergo comprehensive load testing and gauge tests using GO and NOT GO gauges to verify dimensional accuracy and performance. Products have passed evaluations by SGS and other authoritative research institutes to ensure compliance and reliability.

Can I order samples and what is the minimum order quantity?

Yes, RaxPower provides free samples with delivery costs typically paid by the customer. The minimum order quantity is generally 500 pieces.

What are your payment terms and delivery times?

Payment terms are usually T/T with 30% advance and 70% before shipment. Delivery time for 10,000 pieces is typically 3 weeks. For urgent requests, contact us directly to discuss expedited options to meet your project timelines.

Is it possible to order ball clevises with custom specifications?

We specialize in developing new designs tailored to customer requirements. Tooling costs are generally covered by the customer, but if the order quantity exceeds 5,000 pieces, we refund the tooling cost upon order confirmation, making custom solutions cost-effective for larger volumes.

Get A Quick Quotation Today