Insulator fittings are metallic hardware components that connect and secure insulators to poles, towers, or structural supports in electrical power systems. They maintain electrical insulation between conductors and grounded structures while supporting mechanical loads in overhead transmission lines, distribution networks, substations, and railway electrification systems.

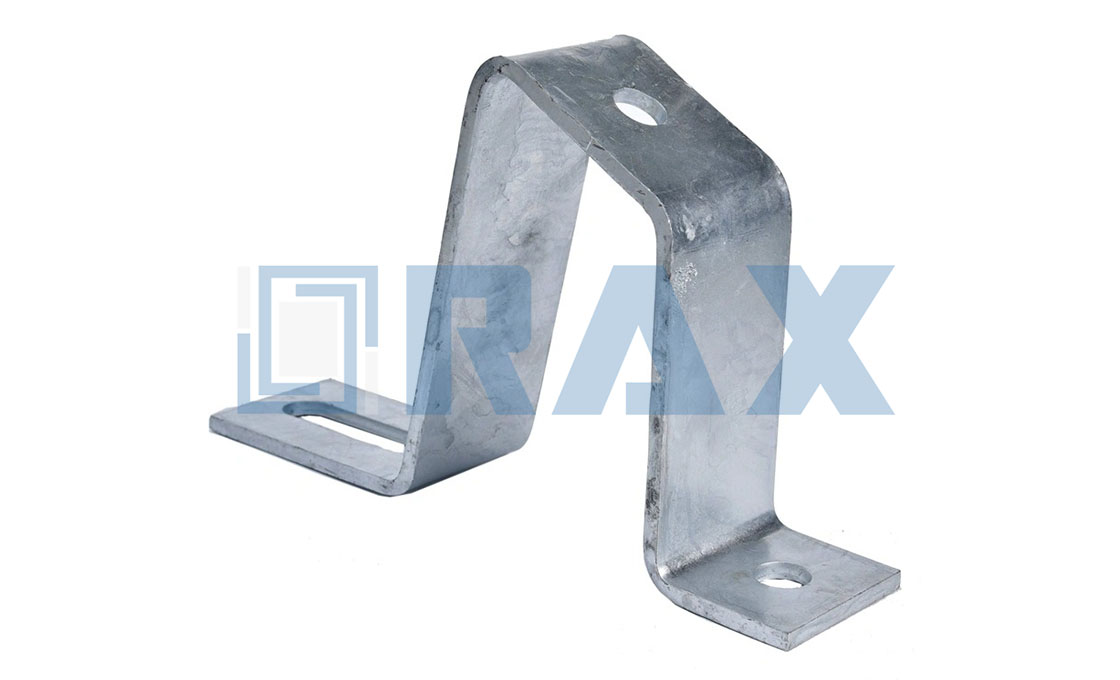

These fittings are categorized by function and installation method. Suspension fittings like ball sockets attach suspension insulators for free-hanging conductors. Tension fittings such as dead-end clamps secure tension insulators in high-stress locations. Line post fittings provide rigid support on poles or crossarms, while pin fittings hold pin-type insulators in low to medium-voltage systems. Specialized variants include arcing horns for overvoltage protection and vibration dampers for conductor stability.

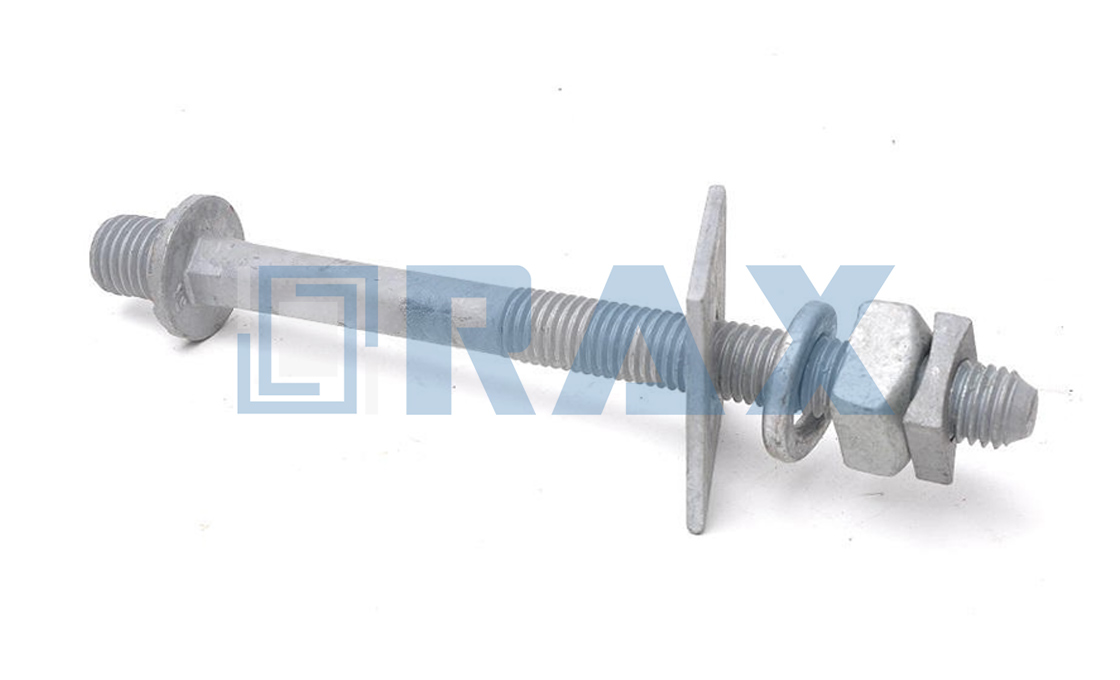

Materials are selected for strength, durability, and environmental resistance. Galvanized steel offers corrosion resistance for suspension and tension applications. Aluminum alloys provide lightweight alternatives with good corrosion properties. Ductile iron delivers mechanical strength under high stress, while stainless steel suits coastal or industrial environments. Fittings are rated for voltage levels up to 123 KV and load capacities of 70-120 KN, with designs complying with International Electrotechnical Commission (IEC), American National Standards Institute (ANSI), and International Organization for Standardization (ISO) standards to ensure reliability and safety across diverse operating conditions.

Trusted Insulator Fitting Supplier with 21 Years of Expertise

RaxPower is the most trusted and leading manufacturer, supplier and exporter of Insulator Fittings. Established in 2003 in Hebei Province, China, with 21 years of expertise, we specialize in delivering high-quality fittings for diverse electrical needs.

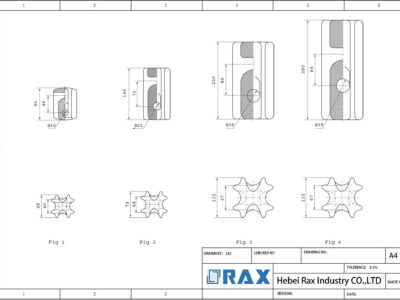

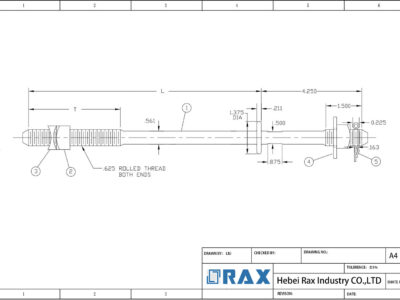

Our fittings are precisely manufactured using supreme grade raw materials and advanced technology like hot forging, ensuring greater strength and accurate dimensions for reliable performance. Our quality controllers implement rigorous checks at every step, from raw material selection to multi-stage testing, with all products reviewed twice before packing.

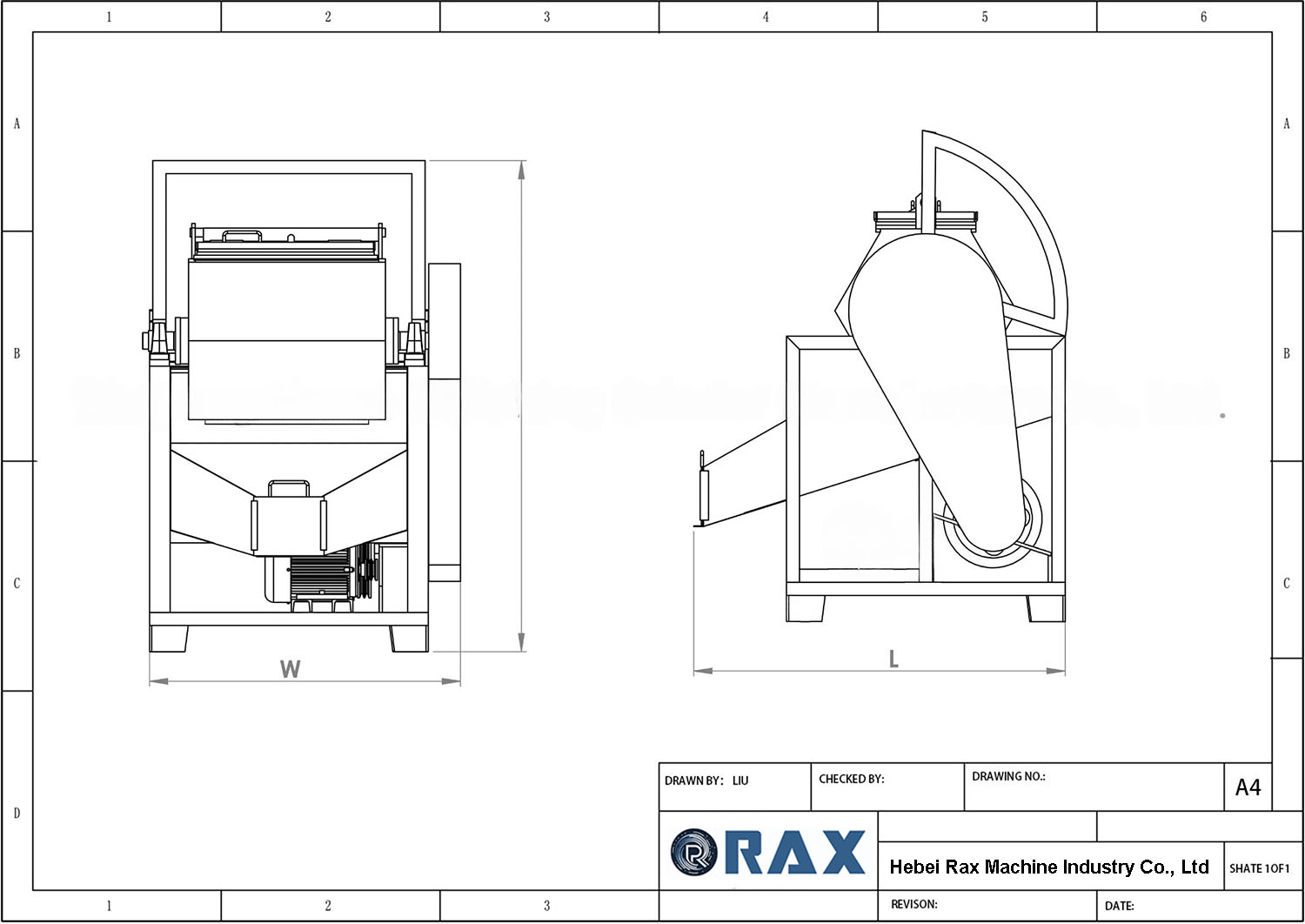

We utilize automatic machines for uniform sizing and hot-dip galvanizing that meets ISO 1461 standards, with a mean coating thickness over 85 microns, guaranteeing durability and corrosion resistance. We offer these Insulator Fittings in both standard and customized options to meet various electrical applications, including pole line and substation fittings, supported by our 17,000 sqm production workshops and efficient delivery systems.

Our high-quality products are well recognized by customers worldwide, fostered by a culture of trust and dedication to exceptional performance. Contact us today with your requirement for the best prices.

Other Products You May Like

Frequently Asked Questions (FAQS)

What are insulator fittings and where are they used?

Insulator fittings are metallic components that connect and secure insulators to transmission towers, poles, or other structural supports, providing a mechanical link between the insulator and the conductor or supporting structure. They are used in high-voltage transmission lines, medium and low-voltage distribution networks, substations for connecting insulators to busbars and equipment, railway electrification systems, and telecommunication infrastructure. RaxPower's fittings ensure mechanical stability and electrical insulation across all these applications while withstanding harsh environmental conditions, mechanical stress, and electrical loads over extended periods.

What are the key benefits of using quality insulator fittings?

Quality insulator fittings provide enhanced system reliability by minimizing mechanical failure or electrical faults, durability through materials that withstand extreme conditions, flexibility for customized project requirements, and cost-effectiveness from reduced maintenance needs. RaxPower's fittings feature compact structure, smooth surface, no moisture absorption, sufficient insulation and mechanical strength, and are made from corrosion-resistant materials that lower overall lifecycle costs by minimizing operational disruptions and reducing the need for frequent replacements.

What types of insulator fittings are available?

Insulator fittings include suspension fittings for attaching suspension insulators to towers, tension fittings for supporting conductors under mechanical tension, line post fittings for rigid support on distribution lines, pin fittings for securing pin-type insulators, and specialized fittings like arcing horns or vibration dampers. Specific components include ball hooks, clevis, yoke plates, and U-bolts, all designed to meet diverse application needs including railway electrification and telecommunication systems like ADSS/OPGW.

What materials are used in manufacturing insulator fittings?

Insulator fittings are made from galvanized steel for strength and corrosion resistance, aluminum alloys for lightweight and corrosion resistance, ductile iron for excellent mechanical strength, and stainless steel for superior corrosion resistance in coastal or industrial environments. RaxPower ensures all materials meet high-quality standards and undergo rigorous testing including load tests and galvanized thickness checks for longevity and performance.

How do I select the right insulator fittings for my project?

Consider the voltage level of your system, load capacity requirements for mechanical and electrical loads, environmental conditions such as humidity and temperature, compliance with international standards like IEC or ANSI, and compatibility with your insulator type and size. RaxPower provides fittings engineered to meet these criteria and relevant international standards, ensuring safety, performance, and technical precision for your specific application.

What is involved in installing and maintaining insulator fittings?

Installation involves cleaning the structure, positioning the hardware for adequate support, securely attaching it with fasteners like bolts or clamps, placing the insulator onto the fittings, and performing final checks for alignment and tightness. Optional testing may include electrical or load tests. Maintenance requires regular inspection for wear, damage, or corrosion, with replacement of components as needed to maintain system reliability and safety.

What is your capacity for handling large-scale orders and delivery timelines?

RaxPower can deliver large quantities of up to 2000 pieces per month and typically ensures delivery within 30-45 days, tailored to meet tight project schedules. Our efficient manufacturing processes, including automation and strict quality control, help manage bulk orders effectively while maintaining consistent quality and timely completion through our robust supply chain.

Get A Quick Quotation Today