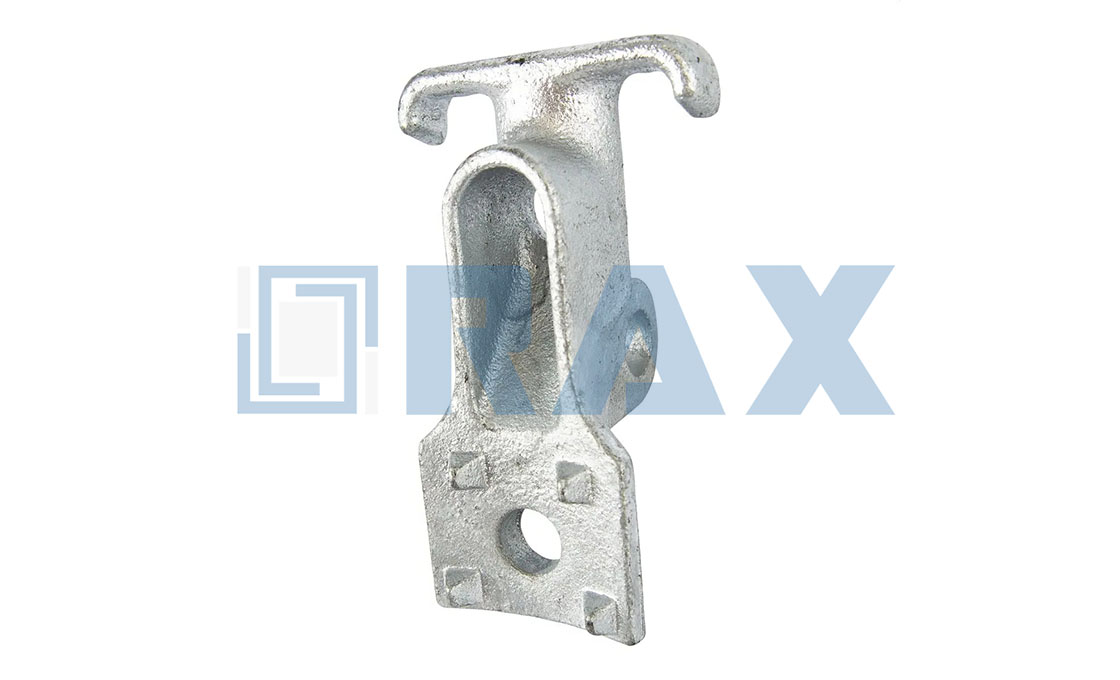

The Pole Eye Plate is a heavy-duty forged fitting that combines an integrated eye with a flat mounting plate to create secure termination points for overhead line systems on utility poles. Commonly called a “Monkey Face” in industry terminology, this component distributes loads evenly across the pole surface and serves as a critical anchor for guy wires, messenger cables, and fiberglass guy strain insulators in electrical and communications networks.

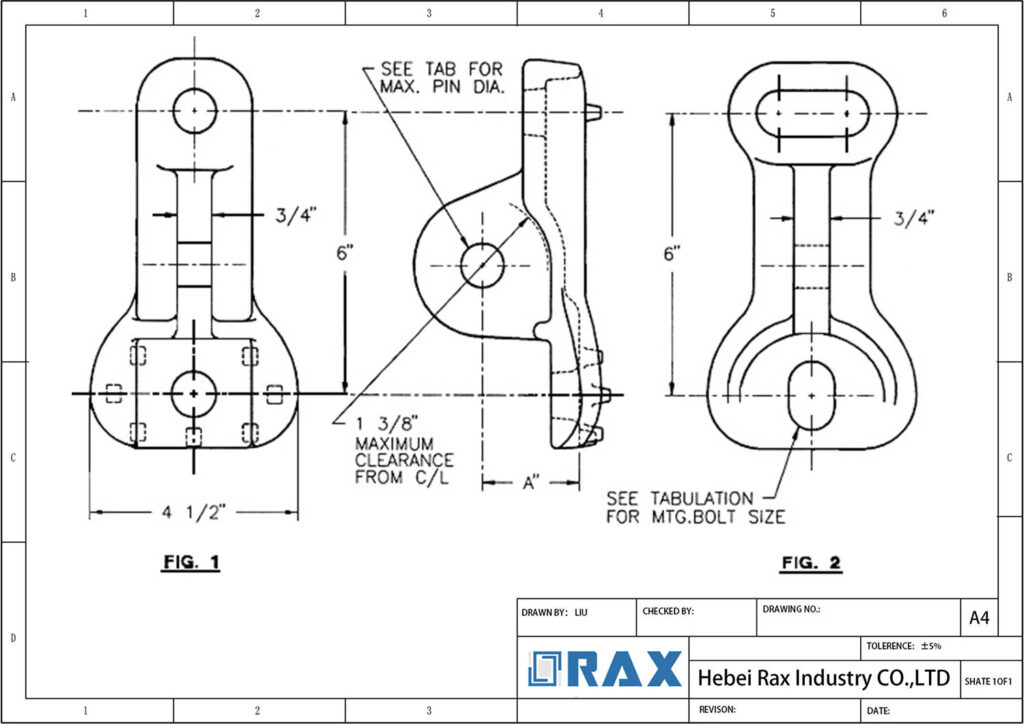

Available in single, double, and triple eye configurations, the plate offers working load ratings from 30 kN to 70 kN (20,000 to 42,000 lbs ultimate strength). Construction typically uses ductile iron per ASTM A-536 or hot-dip galvanized steel meeting ASTM A153 standards, providing environmental resistance and load-bearing capacity. Eye diameters accommodate standard clevis pin sizes from 5/8 to 7/8 inch, while plate profiles can be as narrow as 1 3/4 inches wide.

Working load capacity maintains 100% rating up to 30 degrees from vertical and reduces to 85% between 30 and 45 degrees. Installation on wooden poles requires through bolts or lag screws with torque values of 75 ft-lbs for 5/8 inch bolts and 100 ft-lbs for 3/4 inch bolts. Minimum vertical spacing between multiple plates should be 12 inches for wooden poles and 18 inches for concrete poles to ensure structural integrity.

Pole Eye Plate Manufacturer

Hardware for deadending conductor and guy wires, offered by RaxPower, a trusted industry leader established in 2003 with over 21 years of specialized manufacturing experience in pole line hardware.

The Pole Eye Plate is cast from ductile iron per ASTM A-536 and hot-dip galvanized per ASTM A-153, ensuring superior durability and corrosion resistance for long-term reliability in utility applications. Rated for 21,000 lbs at 45 and 90 degrees, it features a wide base for stabilization and accommodates clevis pins up to 7/8 inch, designed to meet rigorous load demands.

All RaxPower products are manufactured in compliance with applicable electric utility and communications industry standards, reflecting the company’s commitment to efficient, cost-effective, and high-quality processes. This dedication is realized through advanced hot forging technology, which enhances the Pole Eye Plate’s strength and dimensional accuracy, while automated production and strict quality control—including load testing and galvanization per ISO 1461—guarantee consistent performance and on-time delivery.

| Parameter | Value |

|---|---|

| Material | Ductile iron or hot-dip galvanized steel |

| Finish | Hot-dip galvanized per ASTM A153 for galvanization, ASTM A-536 for ductile iron casting |

| Working Load Capacity | 30 kN to 70 kN |

| Ultimate Strength | 20,000 to 42,000 lbs |

| Eye Diameter | 5/8 inch to 7/8 inch |

| Plate Width | As slim as 1 3/4 inches |

| Mounting Bolt Sizes | 5/8″ or 3/4″ through bolts |

| Configurations | Single, double, triple eye |

| Weight | Varies by model |

| Angle Range | 10 to 90 degrees |

| Installation Torque | 75 ft-lbs for 5/8″ bolts, 100 ft-lbs for 3/4″ bolts |

| Spacing Requirements | 12 inches for wooden poles, 18 inches for concrete poles |

| Standards | ASTM A153, ASTM A-536 |

| Reinforced Edge Design | Yes |

Frequently Asked Questions (FAQS)

What are the different types of pole eye plates available?

Pole Eye Plates come in three main configurations: single eye (30kN), double eye (50kN), and triple eye (70kN) designs. Each type features different mounting hole patterns and eye orientations to accommodate specific load requirements and installation configurations in utility applications.

What materials and standards ensure durability and compliance?

Pole eye plates are constructed from hot-dip galvanized steel (ASTM A153) or ductile iron (ASTM A536), ensuring corrosion resistance and strength. RaxPower employs strict quality control including raw material selection, multi-stage testing, and load tests per IEC 120 standards. Products pass SGS tests and authoritative research institute verifications, guaranteeing 100% quality before packing.

What are the compatible hardware dimensions?

The eye diameter accommodates standard 5/8″ and 3/4″ hardware for secure connections. Guy wire sizes from 1/4″ to 1/2″ fit with appropriate thimble clevis hardware, while specialized heavy-duty models support larger sizes up to 5/8″.

What are the installation requirements for pole eye plates?

For wooden poles, torque 5/8″ through bolts to 75 ft-lbs and 3/4″ bolts to 100 ft-lbs. For banding on concrete or steel poles, tension according to manufacturer specifications. Maintain minimum vertical spacing of 12 inches on wooden poles and 18 inches on concrete poles to ensure proper load distribution.

How does installation angle affect load capacity?

Working load capacity remains at 100% for angles up to 30° from vertical. For angles between 30° and 45°, capacity reduces to 85%. Installation angles exceeding 45° are not recommended due to significantly reduced load-bearing capability.

Do you offer custom manufacturing for specific design requirements?

Yes, we produce pole eye plates based on customer drawings and specifications using sand casting and hot forging processes for greater strength and accurate sizing. RaxPower's R&D team collaborates with clients to develop components meeting exact requirements, ensuring consistent quality and cost savings.

What are your capabilities for bulk orders and large projects?

We provide OEM services with automation and semi-automatic molds for efficient production at scale. Our 17,000 square meters of production workshops and 5,000 square meters of warehouses ensure timely delivery. Products are packaged in cartons and plywood pallets for secure shipment, meeting project timelines reliably.

How do you support distributors with product variety and competitive pricing?

As a one-stop global supplier, RaxPower leverages efficient manufacturing and economies of scale to offer competitive wholesale prices. Our comprehensive catalog covers overhead, transmission, and distribution hardware, providing extensive product variety to support distributors' inventory needs and profit margins.

Get A Quick Quotation Today