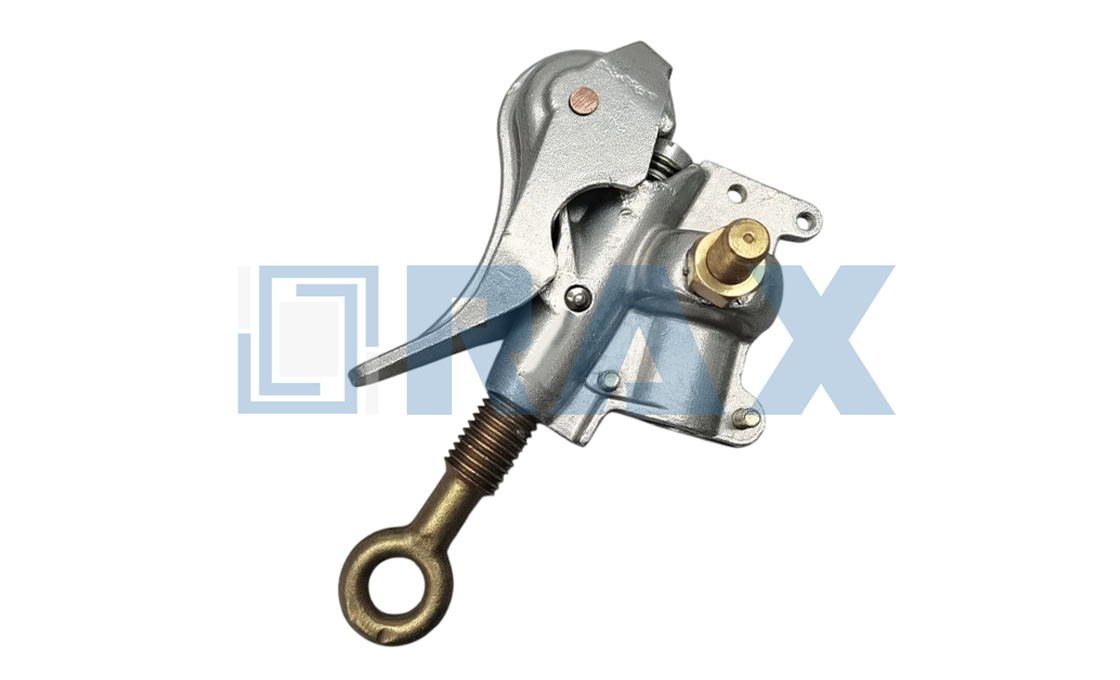

The DuckBill Grounding Clamp provides secure connections in grounding and jumper assemblies for utility and industrial electrical systems. Its snap-on close mechanism enables quick installation, reducing setup time during field operations while ensuring reliable performance across diverse environments.

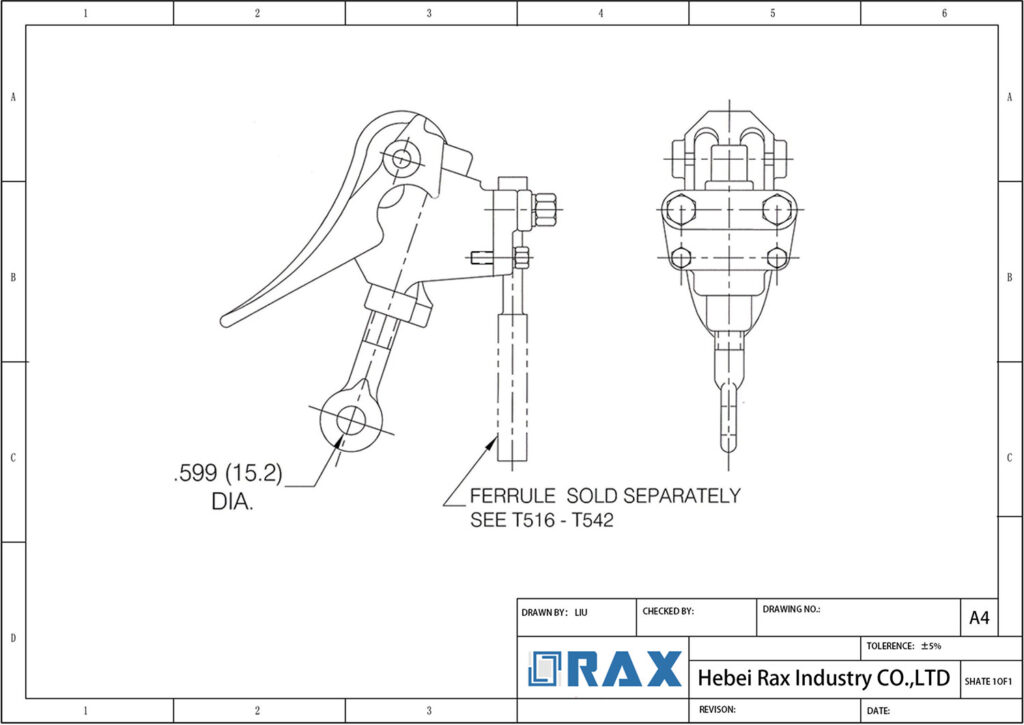

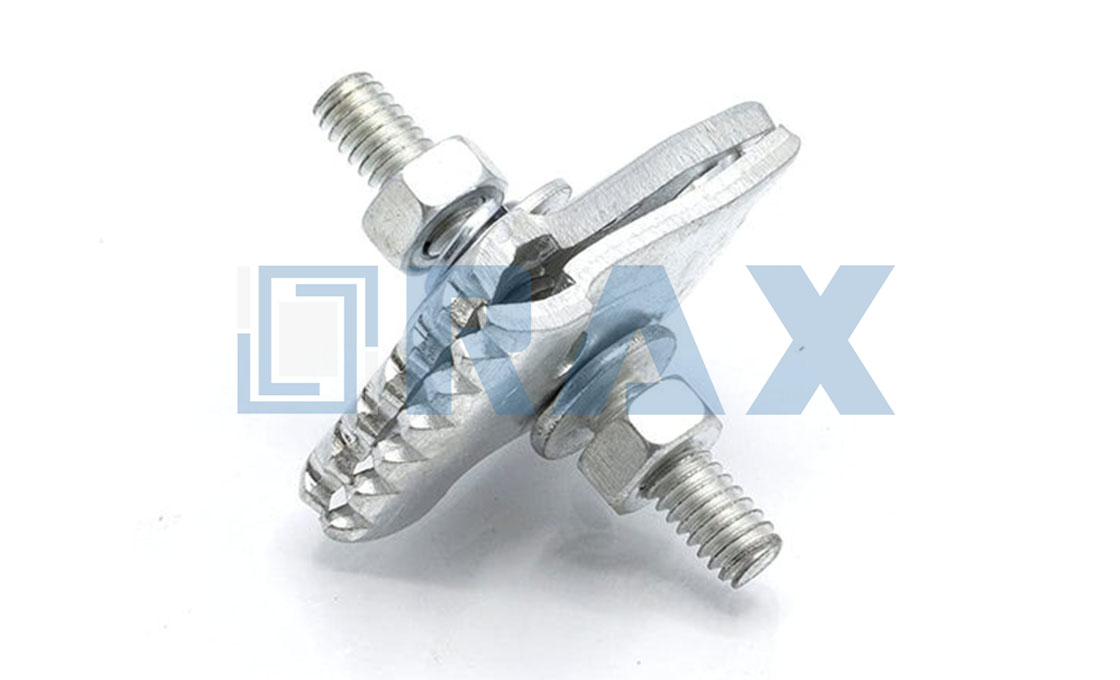

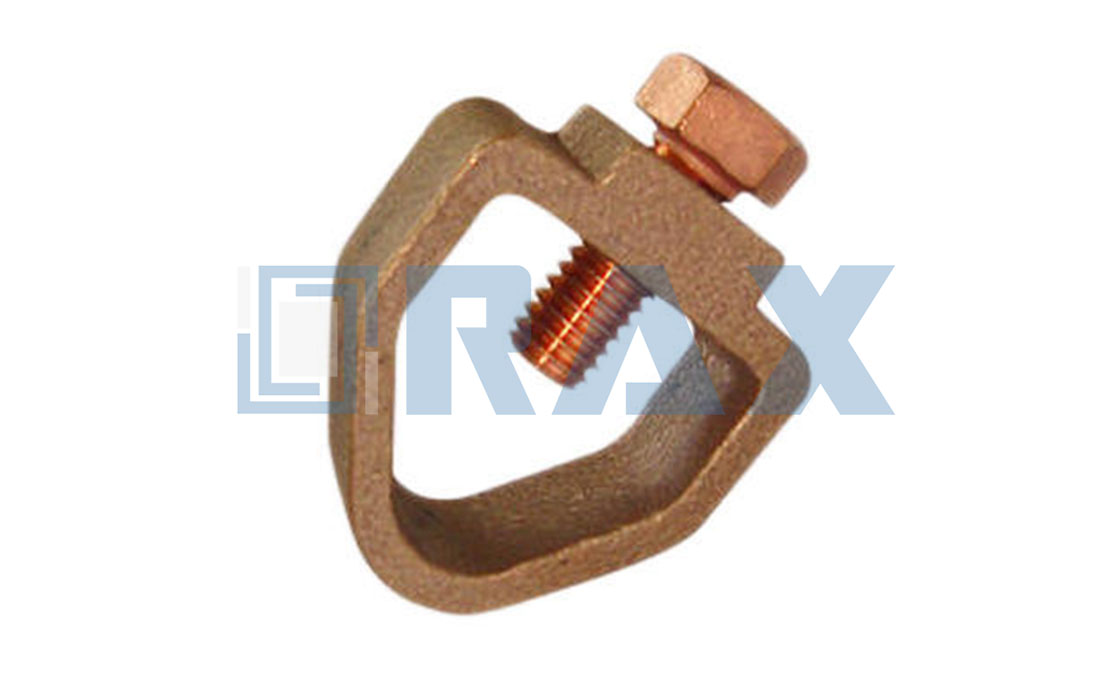

The clamp features an aluminum body for corrosion resistance and typically includes a bronze eyescrew for enhanced durability and mechanical strength. These materials provide excellent electrical conductivity and longevity in grounding applications. Models accommodate jaw openings from 0.162 to 1.66 inches, with smooth or serrated edges to suit different conductor types. The threaded ferrule uses 5/8-11 Unified National Coarse (UNC) threads and supports cable sizes from #2 American Wire Gauge (AWG) to 4/0.

Electrically, the clamp maintains a continuous current rating of 400 amperes and handles maximum fault currents of 43 kA for 15 cycles or 30 kA for 30 cycles. It accommodates main conductors from #6 solid copper to 1113 kcmil Aluminum Conductor Steel Reinforced (ACSR), maintaining low resistance and stable performance under fault conditions.

Installation requires 250 in-lb torque for the eyescrew and ferrule to ensure connection integrity. The design includes a lubrication chamber for thread maintenance and stress relief features to minimize cable damage. The clamp complies with American Society for Testing and Materials (ASTM) F855 standards and meets Grade 5 or 5H fault current testing requirements.

DuckBill Grounding Clamp – Premier Manufacturer

RaxPower’s design philosophy is to maximize the utility of our grounding clamps through innovative design and rigorous testing. Established in 2003 with over 21 years of experience, RaxPower leverages advanced manufacturing processes like hot forging to ensure superior strength and precision. The DuckBill Grounding Clamp is engineered to withstand asymmetric faults, manufactured to the latest ASTM F855 standard, and verified through independent laboratory testing, including SGS certifications.

This clamp’s universal design allows it to be used on conductors, round bus bars, grounding studs, and ball studs, so one clamp covers multiple customer needs.

It features a wide profile for secure seating during fault events, a strong H-frame body for lightweight durability, strain relief to dampen whipping effects and protect cable connections, and a lubrication chamber for thread longevity.

Constructed from forged aluminum with serrated jaws, it delivers high electrical performance, with a continuous current rating of 400A and fault currents of 43kA for 15 cycles or 30kA for 30 cycles.

The jaw opening ranges from 0.162 inches to 1.293 inches, accommodating various conductor sizes, and supports jumper cables from #2 to 4/0 with threaded terminals torqued to 250 in-lb.

By eliminating the need for multiple clamps, the DuckBill Grounding Clamp enhances efficiency and reliability in diverse applications. We invite you to explore more of our products and download detailed information.

| Category | Parameter | Value |

|---|---|---|

| General | Clamp Style | Duckbill |

| General | Material | Aluminum body, Bronze eyescrew |

| General | Jaw Type | Smooth or Serrated |

| Dimensions | Jaw Opening – Minimum | 0.162 in |

| Dimensions | Jaw Opening – Maximum | 1.66 in |

| Dimensions | Weight | 1.5 lb |

| Electrical | Continuous Current Rating | 400 A |

| Electrical | Fault Current Rating – 15 cycles | 43 kA |

| Electrical | Fault Current Rating – 30 cycles | 30 kA |

| Electrical | Main Line Conductor – Minimum | #6 Solid Copper |

| Electrical | Main Line Conductor – Maximum | 1113 kcmil ACSR |

| Electrical | Jumper Cable – Minimum | #2 AWG |

| Electrical | Jumper Cable – Maximum | 4/0 |

| Installation | Eyescrew Installation Torque | 250 in-lb |

| Installation | Ferrule Installation Torque | 250 in-lb |

| Installation | Thread Size | 5/8-11 UNC |

| Certifications | Standards | ASTM F855 |

| Certifications | ASTM Grade | Grade 5 or 5H |

Frequently Asked Questions (FAQS)

What is a duckbill grounding clamp and what are its primary applications?

The duckbill grounding clamp is specialized grounding equipment used in jumper assemblies across diverse field applications for utility grids. It features a snap-on close mechanism for quick installation and is designed to handle both routine maintenance and critical grid expansion projects.

What are the electrical specifications and fault current ratings?

The clamp has a continuous current rating of 400A and fault current ratings of up to 43kA for 15 cycles or 30kA for 30 cycles. It complies with ASTM F855 standards, which govern grounding equipment specifications and require independent testing for safety and performance under asymmetric fault conditions.

What materials and jaw types are available?

Clamps are constructed from aluminum or bronze for durability in grounding applications. Jaw types include smooth (for specific conductor ranges) and serrated (for enhanced grip), with jaw openings ranging from 0.162 inches to 2.5 inches to accommodate conductors from #6 solid copper up to large ACSR or MCM sizes.

How is installation performed?

Installation uses a snap-on close design with threaded ferrules. A torque of 250 in-lb is recommended for the eye screw/T-handle and ferrule connections. The clamp is compatible with hotsticks for utility applications, reducing installation time for field crews working on tight schedules.

How does RaxPower ensure quality and reliability for large-scale projects?

RaxPower implements strict quality control including raw material selection, 100% inspection before packing, multi-stage testing (load tests and gauge tests), and advanced galvanization processes. Our extensive manufacturing scale and warehouse capacity enable bulk supply with consistent on-time delivery, meeting the demanding requirements of EPC contractors and utility projects.

Get A Quick Quotation Today