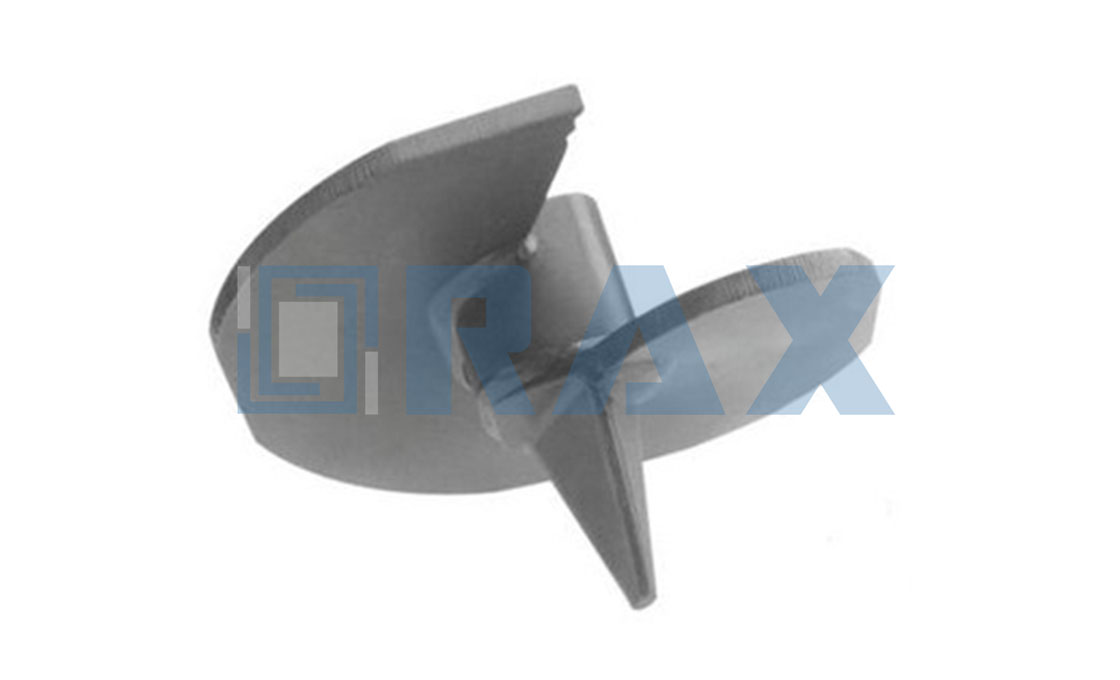

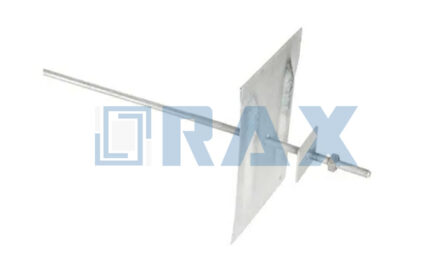

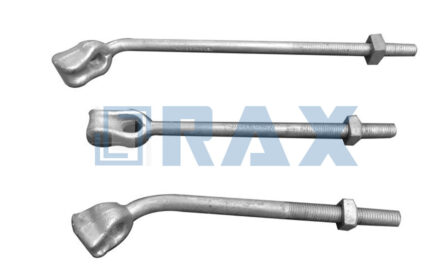

Power Hub Screw Anchor is a helical distribution guy anchor for normal soil conditions requiring average to heavy holding capacities. The one-piece cast steel hub delivers increased torque and bending strength, enabling penetration of tough soils where solid hub anchors may fail. All components are hot-dip galvanized per ASTM A153 for corrosion resistance.

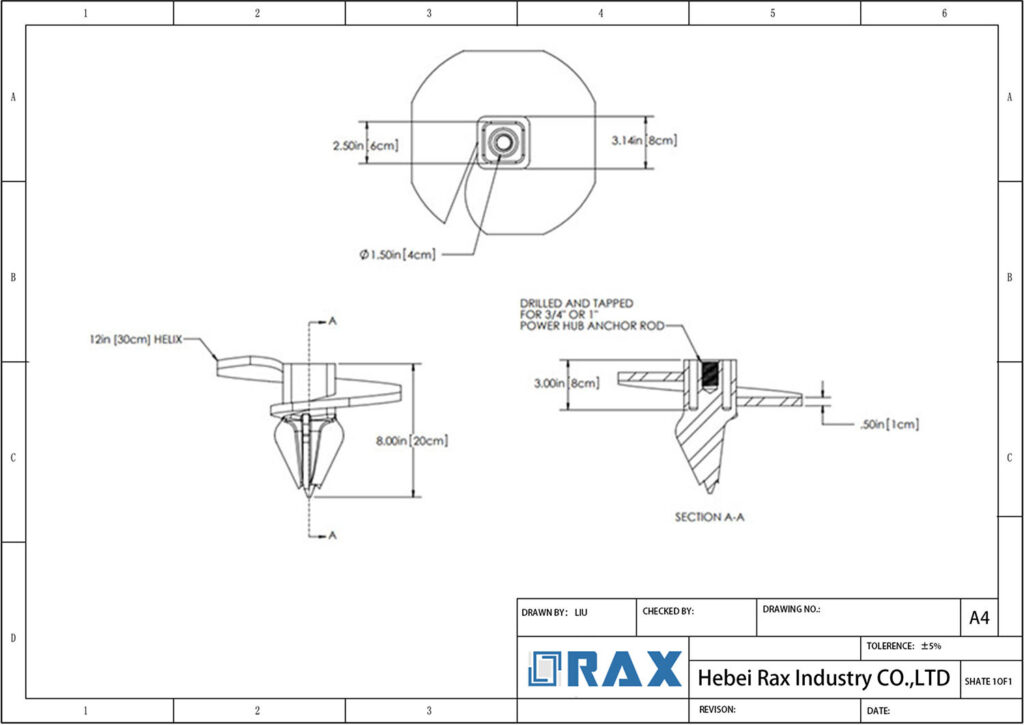

The anchor is available in round-rod (RR) and square shaft (SS) variants, plus Turbo Drive models with socket hubs. Turbo Drive versions offer standard (3/8 inch helix) and heavy-duty (1/2 inch helix) configurations, rated for installation torques from 4,000 to 15,000 ft-lb. Helix diameters range from 8 to 14 inches, with holding strengths reaching 36,000 pounds in suitable soils.

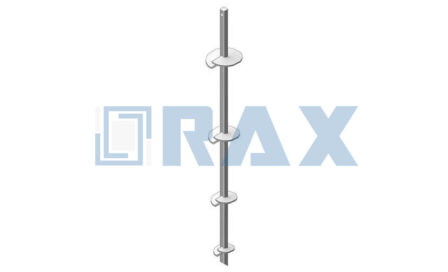

A complete assembly includes a helical hub, anchor rod (5/8, 3/4, or 1 inch diameter), and eyenut (single, double, or triple eye options). Hub size and helix count are selected based on required holding strength, while hub type depends on installation torque. Anchor rod diameter is determined by guy load and installation depth, with standard 7-foot rods and extensions available for installations up to 14 feet below sub-grade.

Installation uses a Kelly Bar adapter and torque tube to apply torque directly to the square hub, with torque measurement required for proper placement. Final exposed anchor height should be 8 to 12 inches above grade.

High-Strength Power Hub Screw Anchor Supplier

Our RaxPower has great advantage in OEM/ODM operation. A Power Hub Screw Anchor offers tension load resistance up to 36,000 lbs depending on soils condition. The complete assembly consists of a helical hub, anchor rod, and eyenut, where helix size and number are selected for required holding strength, and hub type for installation torque requirement. Installation is performed using a power digger with an anchor wrench and torque measurement device connected in series with the wrench, digger, and Kelly Bar. Correct installation is achieved only when the anchor is installed using the appropriate torque for the particular soil and anchor type, as proper selection depends on soil and guying requirements—ensuring optimal performance through cause-and-effect linkage between technique and outcome.

Established in 2003 and located in Hebei Province, China, RaxPower brings 21 years of manufacturing and exporting expertise. We maintain 17,000 square meters of production workshops and 5,000 square meters of warehouses, with over 170 employees including 30 professional technicians and 10 professional engineers. Our commitment to innovation, quality, and cost-effective manufacturing is realized through advanced processes like hot forging for greater strength and accurate sizing, supported by automated machines and strict quality control. All products undergo raw material selection, multi-stage testing, and are reviewed twice before packing, with hot-dip galvanizing achieving mean coating thickness over 85 microns and compliance with IEC 120 standards. We offer expert consultation for customization and tailoring to meet your specific project needs.

| Anchor Type | Installation Torque (ft-lb) | Helix Diameter (in) | Tapped for Rod Size (in) | Helix Thickness (in) | Max Holding Capacity (lbs) | Standard Pack Quantity | Weight (lbs) | Corrosion Protection | Hub Material |

|---|---|---|---|---|---|---|---|---|---|

| Square Hub, 1-3/8” | 6000 | 8 | 5/8, 3/4, 1 | – | 36000 | 4 | 10 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-3/8” | 6000 | 12 | 5/8, 3/4, 1 | – | 36000 | 4 | 16 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-3/8” | 6000 | 14 | 3/4, 1 | – | 36000 | 3 | 21 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 5500 | 8 | 5/8, 3/4, 1 | – | 36000 | 4 | 11 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 5500 | 10 | 5/8, 3/4, 1 | – | 36000 | 4 | 14 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 5500 | 12 | 3/4, 1 | – | 36000 | 4 | 17 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 5500 | 14 | 3/4, 1 | – | 36000 | 3 | 22 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 7000 | 8 | 3/4, 1 | – | 36000 | 4 | 11 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 7000 | 10 | 3/4, 1 | – | 36000 | 4 | 15 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Square Hub, 1-1/2” | 7000 | 12 | 3/4, 1 | – | 36000 | 4 | 18 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” | 10000 | 8 | 5/8, 3/4, 1 | 3/8 | 36000 | 4 | 11.2 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” | 10000 | 10 | 5/8, 3/4, 1 | 3/8 | 36000 | 4 | 14.2 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” | 10000 | 12 | 5/8, 3/4, 1 | 3/8 | 36000 | 4 | 17.9 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” | 10000 | 14 | 3/4, 1 | 3/8 | 36000 | 3 | 22.4 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” | 15000 | 8 | 3/4, 1 | 3/8 | 36000 | 4 | 13.2 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” | 15000 | 10 | 3/4, 1 | 3/8 | 36000 | 4 | 16.2 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” | 15000 | 12 | 3/4, 1 | 3/8 | 36000 | 2 | 19.9 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” | 15000 | 14 | 3/4, 1 | 3/8 | 36000 | 2 | 24.3 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” Heavy Duty | 10000 | 8 | 5/8, 3/4, 1 | 1/2 | 36000 | 4 | 12.7 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” Heavy Duty | 10000 | 10 | 5/8, 3/4, 1 | 1/2 | 36000 | 4 | 16.7 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” Heavy Duty | 10000 | 12 | 5/8, 3/4, 1 | 1/2 | 36000 | 4 | 21.6 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/4” Heavy Duty | 10000 | 14 | 3/4, 1 | 1/2 | 36000 | 2 | 27 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” Heavy Duty | 15000 | 8 | 3/4, 1 | 1/2 | 36000 | 4 | 14.6 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” Heavy Duty | 15000 | 10 | 3/4, 1 | 1/2 | 36000 | 4 | 18.6 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” Heavy Duty | 15000 | 12 | 3/4, 1 | 1/2 | 36000 | 2 | 23.6 | Hot-dip galvanized per ASTM A153 | Cast steel |

| Turbo Drive, 2-1/2” Heavy Duty | 15000 | 14 | 3/4, 1 | 1/2 | 36000 | 2 | 29 | Hot-dip galvanized per ASTM A153 | Cast steel |

Frequently Asked Questions(FAQS)

What is a Power Hub Screw Anchor?

The Power Hub Screw Anchor is a helical distribution guy anchor designed for normal soil conditions where average holding capacities exist. It features a one-piece cast steel hub that provides increased torque and bending strength. Installation is performed using a torque tube and Kelly bar adapter to apply torque directly to the anchor's square hub.

What are the main applications and available types?

These anchors are used to assemble the rod to the hub for guying systems in utility poles, telecommunications, and railway electrification structures. Two types are available: RR (Round-Rod) and SS (Square Shaft), both designed for heavy-guy loading and consisting of three galvanized components: the lead section, extension shaft, and guy adapter.

How is the Power Hub Screw Anchor installed?

Insert the anchor with the rod into the torque tube while fully engaging the tool locking assembly. Install in line with the guy, selecting rods and eye nuts based on your application. Extensions for both the torque tube and anchor rod are available for deeper installation depths up to 14 feet.

What are the specifications and load capacities?

Specifications include helix sizes from 8″ to 14″, rod diameters of 5/8″, 3/4″, or 1″, installation torques from 6,000 to 15,000 ft-lbs, and thread capacities of 160KN. Holding capacities can reach up to 36,000 lbs depending on soil conditions, making them efficient even in weak soils.

How do I select the right anchor for my project?

Selection depends on soil type, required holding strength, installation torque, guy load, and installed depth. Choose the helix size, number of helices, hub type, rod diameter, and eyenut based on these factors to ensure optimal performance for your specific project requirements.

What quality control measures ensure durability and reliability?

Our anchors are hot-dip galvanized per ASTM A153 for corrosion resistance. RaxPower employs strict quality control including raw material selection, multi-stage testing, load tests per IEC standards, and galvanization thickness checks following ISO 1461 (mean coating >85 microns). All products pass SGS tests and evaluations by authoritative research institutes, ensuring 100% quality and full compliance with international standards for critical infrastructure.

Can you handle large volume orders and guarantee on-time delivery?

Yes, we are equipped to supply large orders with our 17,000 sqm production workshops, 5,000 sqm warehouses, and automated processes for accurate sizing and uniform quality. Standard pack quantities (e.g., 4 or 25 pieces) are available. With over 170 employees and efficient supply chain management, RaxPower ensures on-time delivery for bulk projects including utilities, EPC contractors, renewable energy installations, and railway electrification.

Get A Quick Quotation Today