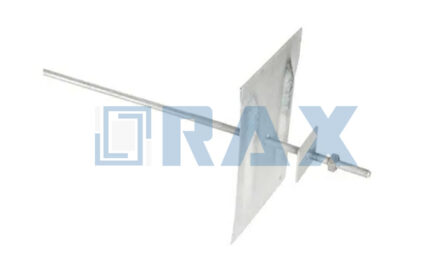

Helical tieback anchors provide lateral support for retaining walls and earth retention structures, stabilizing excavations, cuts, and slopes under lateral loads from soil and water. The system comprises a central steel shaft with one or more helical bearing plates welded to it, forming screw threads with uniform pitch that transfer load from the shaft to the soil through efficient force distribution.

Installation involves rotating the anchor into the ground using rotary drilling equipment, with torque continuously monitored to correlate with holding capacity. The process generates no spoils and requires no grout curing, allowing immediate loading and proof testing once minimum depth is reached in load-bearing soil. This eliminates delays associated with curing or de-watering and enables deployment in various weather conditions and tight access areas.

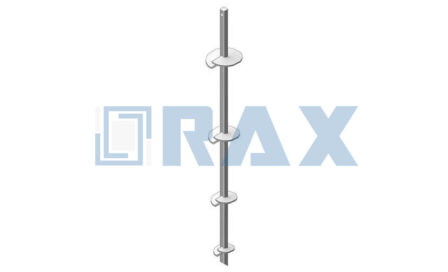

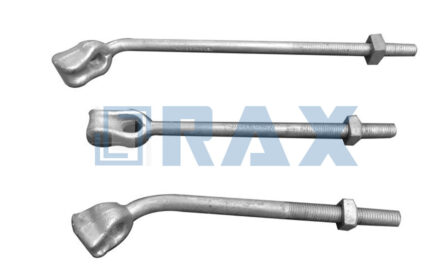

System components include lead sections with helical plates, plain or helical extensions to reach competent soil strata, and anchor terminations such as threaded studs or adapters for wall plate connections. Shaft sizes range from 1-1/4 inch to 2-1/4 inch square, with helix diameters from 6 inches to 14 inches. Capacity specifications reach up to 200,000 pounds per anchor, with load capacity directly proportional to installation torque, typically around 10 pounds per foot-pound, ensuring predictable performance and site-specific adjustments based on soil conditions.

Applications include retaining walls, building site preparation, roadways, levees, dams, seawalls, and bulkheads across residential, commercial, and industrial settings for both new construction and remedial projects.

Trusted RaxPower Helical Tieback Anchor Wholesaler with 21+ Years of Expertise

RaxPower is a leading manufacturer of customized, high-capacity helical tieback anchors and systems. With over 21 years of experience in manufacturing and exporting, and our superior patented inertia welding technology, we provide the strongest tieback anchors for soil stabilization and foundation repair. Our systems are designed to install faster, perform stronger, and last longer in any soil, any terrain, anywhere.

Advantages of Helical Tieback Anchors

- Immediate proof-testing: No waiting for grout to cure, saving time and money.

- All-weather installation: Use conventional drilling equipment without concrete trucks or grout pumps.

- Predictable holding strength: Reliable performance in all soil conditions.

- No excavation required: Ideal for tight spaces and limited access areas.

- Clean installation: Generates no spoils and no messy grout.

Typical Applications

- Building-site preparation

- Roadways and retaining walls

- Levees and dams

- Slope retention and excavation support

We care deeply about our certified installers and customers, offering full support and trust. Learn how to self-install or add helical tieback anchors to your services by becoming a certified installer today.

| Parameter | Specification |

|---|---|

| Shaft | |

| Size | 1-1/4″ to 2-1/4″ square |

| Helix | |

| Diameter Range | 6″ to 14″ |

| Configurations per Lead Section | 2 to 4 helices |

| Capacity | |

| Maximum Ultimate Capacity | 200,000 lbs per anchor |

| Torque-to-Capacity Factor | 10 lbs per ft-lb |

| Components | |

| Material / Corrosion Protection | Steel, hot-dip galvanized per ASTM A153 |

| Lead Section Lengths | 30″ to 124″ |

| Extension Lengths | Plain: 37″ to 124″; Helical: 48″ to 124″ (with 14″ diameter helices in single, double, or triple configurations) |

| Anchor Termination | Threaded studs or adapters for various thread bars (e.g., 1″ to 1-3/8″) |

| Installation | |

| Equipment | Common rotary drilling equipment |

| Immediate Loading Capability | Yes, no grout cure required |

Frequently Asked Questions(FAQS)

What is a helical tieback anchor?

A helical tieback anchor is a segmented deep foundation system with helical bearing plates welded to a central steel shaft. The load is transferred from the shaft to the soil through these bearing plates, providing lateral support for earth retention structures like retaining walls.

What are the main benefits of using helical tieback anchors?

Helical tieback anchors offer quick installation with minimal vibration or soil disturbance, immediate load capacity without curing time, no spoils removal, and cost-effectiveness. They can be installed in limited access areas and various weather conditions, with predictable holding strength in all soils.

What applications can helical tieback anchors be used for?

Helical tieback anchors are suitable for retaining walls, building site preparation, roadways, levees, dams, revetments, bulkheads, seawalls, and permanent or temporary earth retention systems.

How are helical tieback anchors installed?

Helical tieback anchors are installed by rotating them into the ground using conventional rotary drilling equipment in almost any weather condition. The installation torque is monitored and correlated to holding capacity, allowing for immediate proof-testing and loading once minimum depth is reached. No grout or concrete is required, eliminating curing time and reducing project timelines.

What is the load capacity of helical tieback anchors?

Capacities can reach up to 200,000 pounds per anchor, depending on soil conditions and helix configuration. The load capacity is proportional to installation torque and the sum of individual helix bearing capacities. Typical installation and testing rates can reach 30-40 anchors per day.

How do helical tieback anchors help control costs compared to traditional methods?

The system eliminates grout curing, de-watering, and spoils removal, reducing labor and equipment expenses while achieving high anchor load capacities. The method minimizes site disturbance, delays, and overall project costs.

What engineering support is available for custom projects with unique soil or load requirements?

An expert team of geotechnical and structural engineers provides educated support for unique job sites, and design software like HeliCAP® helps quickly derive the proper helical tieback anchor for site-specific data and load conditions.

Get A Quick Quotation Today