The Pole Top Make Off secures and terminates conductors at utility pole tops, providing stable connections in power distribution and telecommunications networks. It clamps the pole to the earth, replacing wedge clamps and UT (Universal Tangent) clamps for improved efficiency. Constructed from galvanized steel or aluminum alloy, it complies with industry standards and withstands harsh environmental conditions while maintaining system integrity.

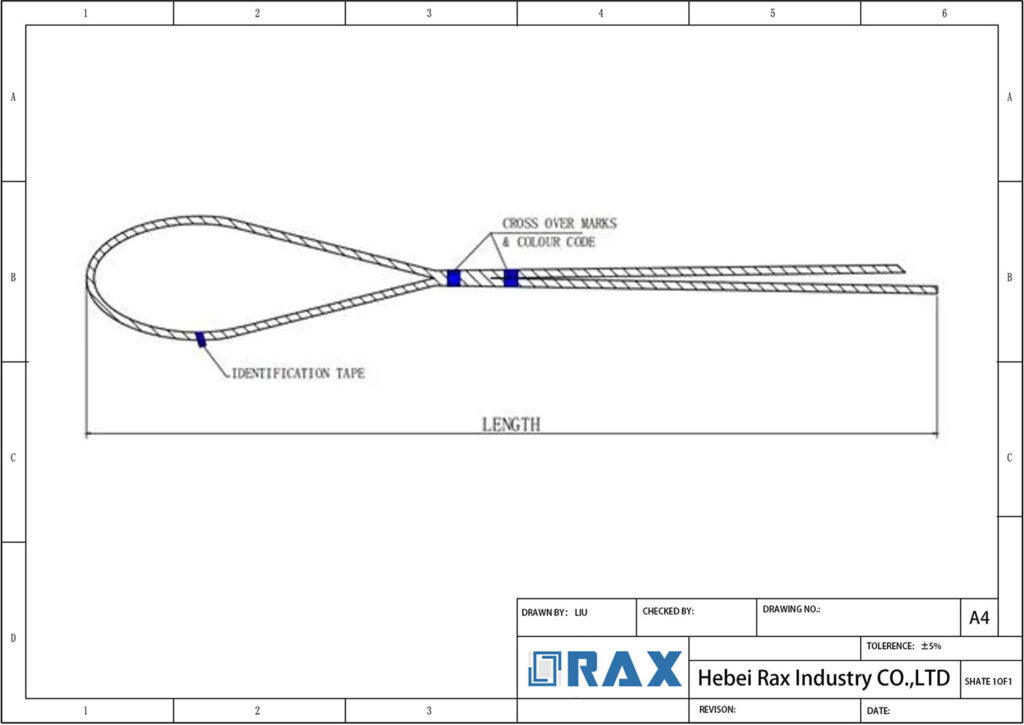

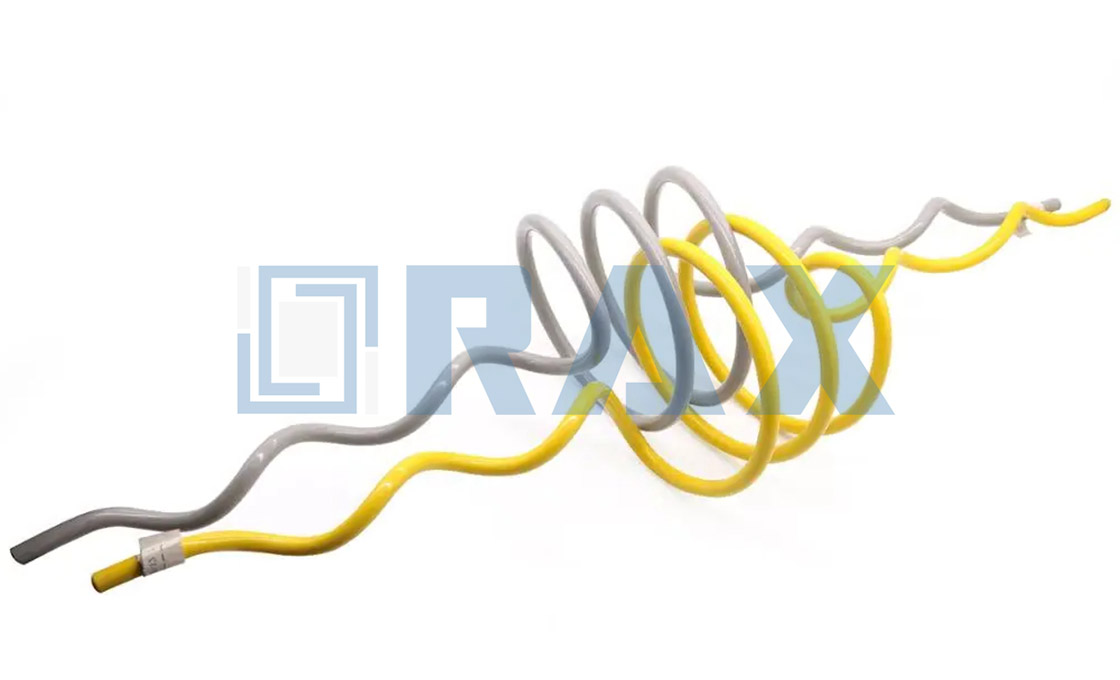

The design features high-strength, corrosion-resistant materials with a secure termination mechanism that anchors conductors firmly to prevent slippage. Pre-twisted legs naturally wind around the wire, creating strong grip force. The simple structure allows easy installation without special tools, reducing labor time and costs. It may incorporate insulation protection to prevent conductor damage and is customizable to various wire sizes and strength requirements.

Key advantages include uniform stress distribution that prevents wire damage and prolongs service life, plus enhanced vibration resistance for durability in high-wind areas. The grip strength reaches at least 95% of the stay wire breaking load. Materials include hot dip galvanized steel wire with strand diameters from 7.21mm to 16.25mm in configurations such as 7/2.00mm or 7/4.00mm, with customizable reference lengths and various strength ratings available.

Applications span power distribution networks, telecommunications systems, industrial installations, and renewable energy setups. It operates in temperatures from -40°C to +60°C with relative humidity up to 95%, withstanding high winds, rain, UV (ultraviolet) exposure, and corrosive environments with salt, chemicals, or industrial pollutants.

RaxPower Pole Top Make Off Wholesaler with IEC Standards

RaxPower, based in Hebei Province, China, is a leading global professional manufacturer of pole line hardware, offering a comprehensive range for power line construction. Our Pole Top Make Off is a specialized component designed for secure electrical connections at utility pole tops, effectively replacing wedge clamps and UT clamps to simplify installation and enhance reliability.

This innovation ensures robust performance while reducing installation time and effort. With over 21 years of experience since our establishment in 2003, we are committed to quality, international standards, and customer satisfaction through continuous innovation.

Our products have passed SGS tests and adhere to IEC standards, featuring durable, weather-resistant construction. We operate from 17,000 square meters of production workshops and 5,000 square meters of warehouses, supported by a team of over 170 employees, including 30 professional technicians.

Strict quality control, from raw material selection to multi-stage testing, ensures high-volume production and global exports to over 50 countries. Send Inquiry to explore our reliable solutions and benefit from timely delivery.

| Parameter | Value |

|---|---|

| Material | Galvanized Steel or Aluminum Alloy |

| Grip Strength | At least 95% of the stay wire breaking load |

| Operating Temperature | -40°C to +60°C |

| Relative Humidity | Up to 95% |

| Standards | Complies with industry standards (e.g., IEC, BS, ASTM) |

| Strand Configurations | Strand diameters from approximately 7.21mm to 16.25mm; common configurations include 7/2.00mm, 7/4.00mm, etc. Reference lengths can be customized upon request. |

Frequently Asked Questions

What is a pole top make off and what is it used for?

The RaxPower pole top make off wraps around the pole top to facilitate termination of the stay strand, firming the pole on the earth and ensuring stable connections in power distribution and telecommunications networks.

What are the key advantages of this product?

RaxPower pole top make offs feature a simple structure with pre-twisted legs for easy hand installation without special tools, reducing labor costs. They provide uniform stress distribution to prevent wire damage and enhanced vibration resistance for extended service life.

What applications are suitable for pole top make offs?

These products are ideal for power distribution networks, telecommunications, industrial and commercial installations, renewable energy systems (wind and solar), and specialized applications like railway electrification.

What materials are used and how do they perform in harsh environments?

RaxPower pole top make offs are constructed from high-strength hot-dip galvanized steel wire or aluminum alloy. They operate effectively in temperatures from -40°C to +60°C, up to 95% relative humidity, and resist corrosion from salt, chemicals, or pollutants. Our hot-dip galvanizing complies with ISO 1461, ensuring mean coating thickness exceeding 85 microns for superior protection.

How is installation performed?

Position the pole top make off at the top of the utility pole. The round head attaches directly to the pole or mounts onto a tension clamp or pole band, while the other end wraps with a short guy grip and mounts onto the insulator pin for secure connection.

Can you accommodate different wire sizes or provide customization?

Yes, we support a full range of sizes and customization. Our products adapt to various standard wire sizes (e.g., 7/2.00mm to 7/4.00mm) and can be customized for different strand diameters (up to 19/3.25mm or more), lengths, and stranding configurations. All products undergo rigorous quality control, including load testing, to meet or exceed industry standards like IEC.

What are your lead times and payment terms for bulk orders?

Typical lead time for bulk orders is 25-35 days upon receipt of advance payment. We accept T/T (Telegraphic Transfer) with 30% deposit before production and balance against copy of Bill of Lading. Samples are available for reference, and sample costs can be deducted from future orders.

Get A Quick Quotation Today