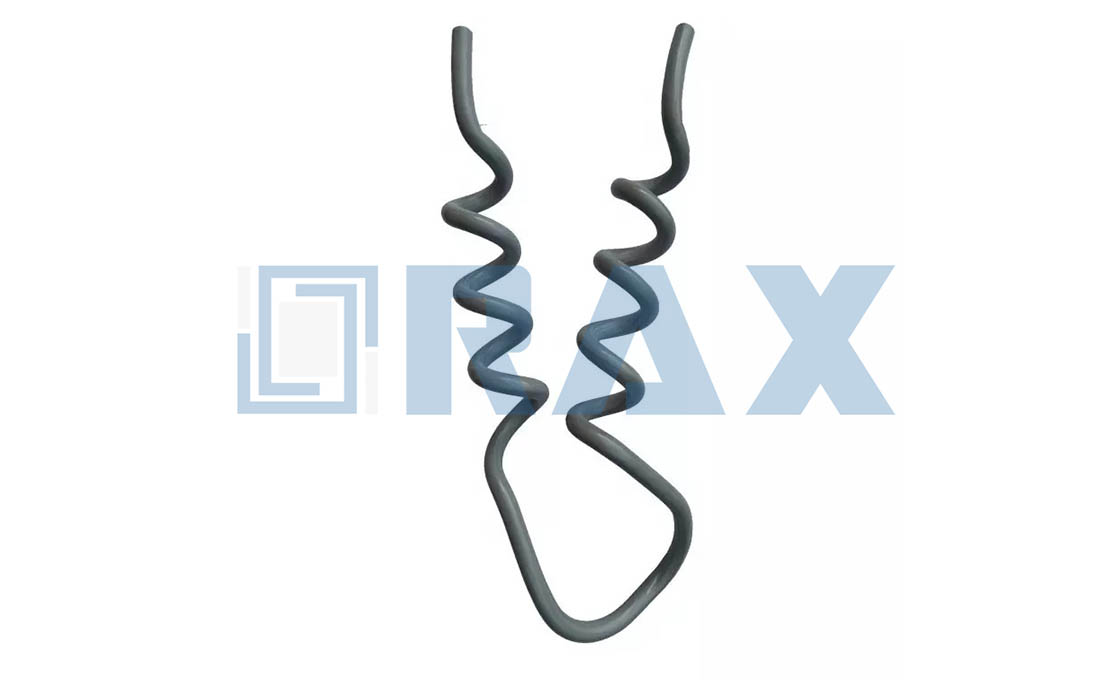

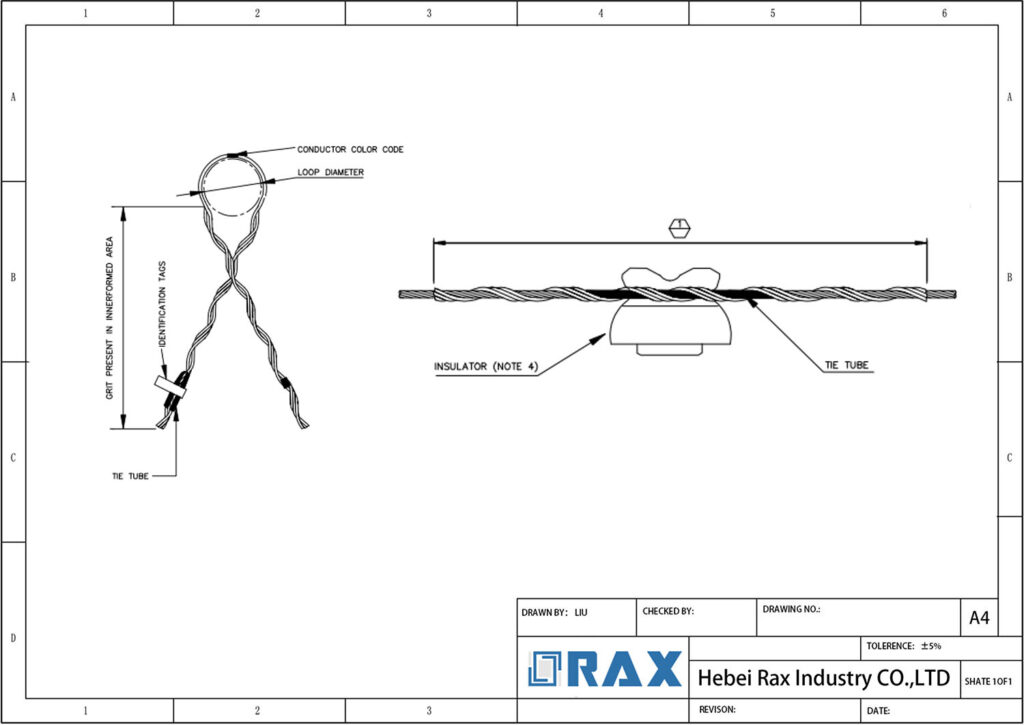

The Insulator Side Tie secures conductors to the side groove of insulators in overhead power distribution systems, serving as an alternative to hand ties or clamp-top methods. Pre-contoured for interchangeable headstyle insulators, it maintains conductor position and integrity while reducing abrasion and enhancing stability in vibration-prone areas. Compatible with AAC, AAAC, ACSR, and plastic-jacketed conductors, the tie can be applied over armor rods or line guards where appropriate dampers are used.

Constructed from high-elasticity Polyvinyl Chloride (PVC), aluminum-clad steel, or semi-conductive plastic coatings, the tie incorporates an elastomer pad with metal variants to cushion the conductor-insulator contact point. UV-stabilized formulations resist sunlight degradation. Color-coding aids installation: inner colors indicate conductor size while outer colors denote insulator neck size—black for C neck (57mm), yellow for F neck (73mm), and green for J neck. The tie accommodates line angles up to 15 degrees for single ties and up to 80 degrees for double ties, with no more than 40 degrees per insulator.

Mechanical properties exceed National Electrical Safety Code (NESC) requirements, developing unbalanced and lift-off loads equivalent to or exceeding hand ties while permitting longitudinal displacement without loosening. The design mitigates aeolian vibration, galloping, and low-frequency sway. Conductor diameter ranges from approximately 0.245 to 1.240 inches, with applied lengths of 533mm to 762mm depending on neck size. Aluminum-clad steel provides high strength, while semi-conductive coatings offer electrical tracking resistance and relieved ends ease application.

RaxPower: Premier Insulator Side Tie Manufacturer

Looking for durable and high-quality PVC insulator ties? Look no further than RaxPower, a leading supplier, manufacturer, and factory based in Hebei Province, China. With over 21 years of industry expertise, we specialize in preformed distribution ties that deliver unmatched reliability and durability.

Our Insulator Side Tie is designed to reinforce the conductor on both sides of the insulator, thereby improving tensile performance and minimizing RIV potential. Utilizing advanced hot forging technology and automated processes in our 17,000 square meter production facility, we ensure each tie offers superior strength, precise sizing, and easy installation.

Our rigorous quality control, including multi-stage testing, load tests, and SGS certifications, guarantees products that exceed ANSI standards by up to 30%. Backed by a lifetime guarantee and a team of 30 professional technicians, we are committed to providing secure, double-support solutions for various applications.

As a one-stop global supplier, we offer a comprehensive range of pole line hardware. So, if you’re looking for quality insulator ties or related products, contact RaxPower today!

| Parameter | Specification |

|---|---|

| Insulator Neck Size | C (57 mm), F (73 mm), J |

| Conductor Diameter Range | 0.245 inch – 1.240 inch |

| Applied Length | 533 mm – 762 mm |

| Weight per Carton | 10 lb – 17 lb |

| Units per Carton | 50 |

| Material | High-elasticity PVC, aluminum-clad steel, or semi-conductive plastic coatings |

| Color Code | Grey or black; inner color indicates conductor size, outer color indicates insulator neck size (Black: C, Yellow: F, Green: J) |

| Line Angle Capacity | Single side tie: up to 15°, Double side tie: up to 80° (with no more than 40° per insulator) |

| Conductor Types | AAC, AAAC, ACSR, plastic-jacketed |

| Mechanical Properties | Exceeds NESC requirements for unbalanced load handling; high abrasion resistance; permits longitudinal displacement without loosening |

| Insulator Compatibility | ANSI C29.5 standards for interchangeable headstyle insulators (polymer or porcelain) |

| Application Scenarios | Vertically-mounted insulators in armless construction or at crossarms; distribution lines, tree wire construction, areas with potential radio interference |

| Additional Features | Pre-contoured design for consistent fit; UV-stabilized formulations available; may include elastomer pad for cushioning; relieved ends on some models for ease of application and tracking resistance |

Frequently Asked Questions

How do insulator side ties compare to traditional hand ties?

Formed side ties are superior to hand ties in vibration-prone areas, providing better abrasion protection, easier installation by hand or with hot sticks, and improved performance against radio influence voltage (RIV). They offer uniform design and can be used over armor rods or line guards.

What materials and standards ensure durability and compliance?

At RaxPower, our formed wire side ties are made from aluminum-clad steel, coated steel with semi-conductive plastic, and high elasticity polymers, ensuring long-term durability and resistance to environmental factors. They are compatible with ANSI C29.5 interchangeable headstyle insulators and comply with utility and railway standards.

What range of applications and specifications do your insulator side ties support?

RaxPower offers a comprehensive range for various insulator neck sizes (C, F, J neck) and conductor types like AAC, AAAC, ACSR, all-aluminum, aluminum alloy, compacted ACSR, and covered conductors. Our products are designed for applications up to 15kV, accommodate line angles up to 80 degrees (with no more than 40° per insulator in severe vibration situations), and are suitable for telecommunications and distribution lines.

What components are included with insulator side ties?

Typically, they include a neoprene rubber tie tube, identification tag with catalog number and conductor range, and color codes for conductor and insulator size identification. Some versions include an elastomer pad for bare conductors to enhance protection.

How do insulator side ties protect against conductor abrasion?

The included tie tube or elastomer pad acts as a resilient cushion, eliminating abrasion damage caused by conductor motion, including low-frequency sway, aeolian vibration, and galloping. This extends the life of the electrical system and reduces maintenance.

Can you ensure on-time delivery for large-scale projects?

Yes, at RaxPower, we utilize automated manufacturing processes and preformed machines for efficient production, ensuring uniform design and accurate sizing. With over 21 years of experience and large production facilities, we can handle bulk orders and maintain on-time delivery. Our 5,000 square meters of warehouses support immediate availability for in-stock items.

How do you achieve cost-effectiveness while maintaining consistent quality?

At RaxPower, we employ strict quality control measures, including raw material selection and multi-stage testing. Our use of preformed machines ensures consistent helical shapes, providing reliable performance and reducing installation time. This results in significant cost savings and perfectly consistent quality for our OEM clients.

Get A Quick Quotation Today