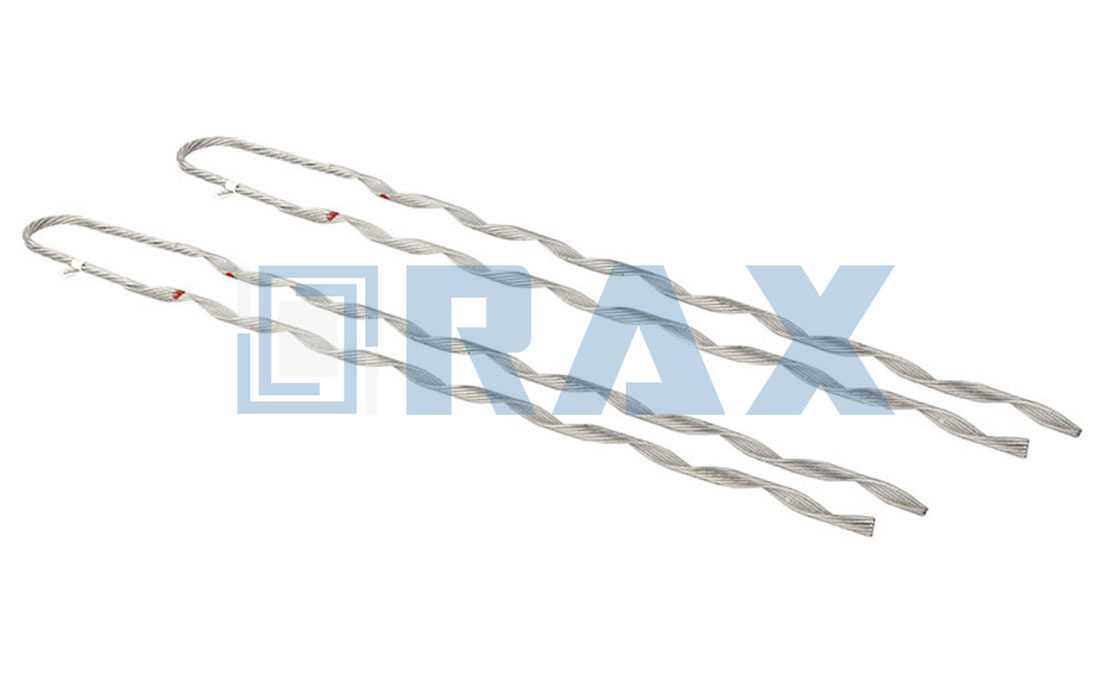

The Formed Wire Dead End is a helical wire component that terminates and secures Optical Ground Wire (OPGW) and All-Dielectric Self-Supporting (ADSS) cables in overhead transmission and distribution systems. It provides a mechanical endpoint handling axial and compressive loads as an alternative to bolted dead-ends.

The design features a wrap-on installation requiring no specialized tools, reducing labor time and complexity. An integrated Current Transfer Tab eliminates separate grounding clamps, lowering material and handling costs. Inner Structural Reinforcing Rods protect the cable from excessive bending strain and distribute loads uniformly to minimize damage to the core and optical fibers. The tab, captured between the OPGW and rods, provides direct electrical connection with fault current ratings from 80 to 150 kA²/sec.

Constructed from corrosion-resistant aluminum clad steel or galvanized steel, the component matches conductor types to prevent electrochemical corrosion. Specifications include diameters from 0.51 to 0.54 inches, lengths up to 48 inches, and holding capacity of 60% to 95% of cable rated breaking strength with component strengths reaching 6500 pounds. Performance validation includes 100 million aeolian vibration cycles and compliance with Institute of Electrical and Electronics Engineers (IEEE) 1138 and IEEE 1591.1 standards.

Primary applications involve OPGW and ADSS cables at line or elevation angle changes exceeding 30 degrees. The dead end can be specified for right or left lay directions to match cable construction, ensuring compatibility across power and telecommunication infrastructure installations.

Expert Formed Wire Dead End Solutions from RaxPower Wholesaler

RaxPower, established in 2003 in Hebei Province, China, is a global leader with over 21 years of experience in manufacturing pole line hardware. We specialize in formed wire products and accessories for power transmission and distribution systems, emphasizing customization and advanced production capabilities.

Our Formed Wire Dead End is engineered to reduce internal stresses and ease handling, ensuring superior performance and longevity.

Unlike wedge type dead-ends, this helically-formed design transfers axial load to a low uniform radial compression, distributing force over the product length to minimize pressure on the cable. This results in secure holding capability that maintains a minimum of 60% of the cable rated breaking strength.

Easy to install with a simple wrap-on application, it prevents conductor distortion and is suitable for various conductor sizes in overhead transmission and distribution.

We accept any customized guy wire dead end grips to meet your specific requirements.

| Parameter | Value |

|---|---|

| Application | For OPGW and ADSS cables, line or elevation angle changes >30° |

| Type | Formed Wire Dead End |

| Installation Method | Wrap-on, no tools required |

| Components | Helically-formed wire, Structural Reinforcing Rods (SRR), Current Transfer Tab (CTT), Thimble Clevis |

| Parameter | Value |

|---|---|

| Diameter Range | 0.51 to 0.54 inches |

| Length | 48 inches |

| Weight | Varies by model |

| Parameter | Value |

|---|---|

| Minimum Holding Strength | 60% to 95% of cable’s rated breaking strength |

| Component Strength | Up to 6500 pounds |

| Maximum Initial Tension | Up to 1000 pounds |

| Maximum Loaded Tension | Up to 2500 pounds |

| Parameter | Value |

|---|---|

| Fault Current Rating | 80 to 150 kA²/sec |

| Bonding Method | Integrated Current Transfer Tab |

| Parameter | Value |

|---|---|

| Testing Standards | IEEE 1138, IEEE 1591.1 |

| Aeolian Vibration Cycles | 100 million cycles |

| Galloping Cycles | 100,000 cycles |

| Parameter | Value |

|---|---|

| Lay Direction | Right or left lay |

| Reusability | SRR and dead-end components can be reused once for retensioning; hardware reusable if in good condition |

| Parameter | Value |

|---|---|

| Available Accessories | Grounding wire assemblies, linkage hardware, extension links, anchor shackles |

Frequently Asked Questions

What is a formed wire dead end and how does it work?

RaxPower's formed wire dead end is a helically-formed wire design that provides a simple, wrap-on application. It uses an inner layer of structural reinforcing rods (SRR) and an outer dead-end component to distribute axial and compressive loads over the OPGW, reducing stresses on the central core and optical fibers. The wrap-on installation requires no tools for basic setup, and the integrated Current Transfer Tab is captured between the OPGW and SRR, eliminating separate fasteners.

How do your dead ends reduce project costs and timelines?

The wrap-on design accelerates installation without specialized tools, reducing labor time and expenses. The integrated Current Transfer Tab eliminates the need for separate grounding clamps, cutting material costs and simplifying handling. These features combine to reduce overall project costs and speed up completion.

What materials are used and what is their durability?

Dead ends are constructed from corrosion-resistant materials, such as galvanized steel or aluminum clad steel, to prevent degradation and provide durable performance in harsh environments, extending service life.

What testing standards do your dead ends meet?

Our dead ends are tested to IEEE 1338, IEEE 1138, and IEEE 1591.1 specifications. They pass performance tests of 100 million aeolian vibration cycles and 100,000 galloping cycles, ensuring they maintain integrity and reliability under dynamic loads and extreme weather conditions.

What components are included in the standard assembly?

The standard assembly includes the Current Transfer Tab (CTT) with a fault current rating of 80 to 150 kA²/sec and a 42k lbs Thimble-Clevis. Optional accessories like Grounding Wire Assemblies and Linkage Hardware are available.

Can the dead end components be reused?

The structural reinforcing rods and dead-end components can be reused once for retensioning after initial installation. Other hardware components may be reused if they are in good condition.

What lay directions are available for the dead end?

Standard designs are for Left-Hand-Lay OPGW. For Right-Hand-Lay applications, please contact RaxPower.

Get A Quick Quotation Today