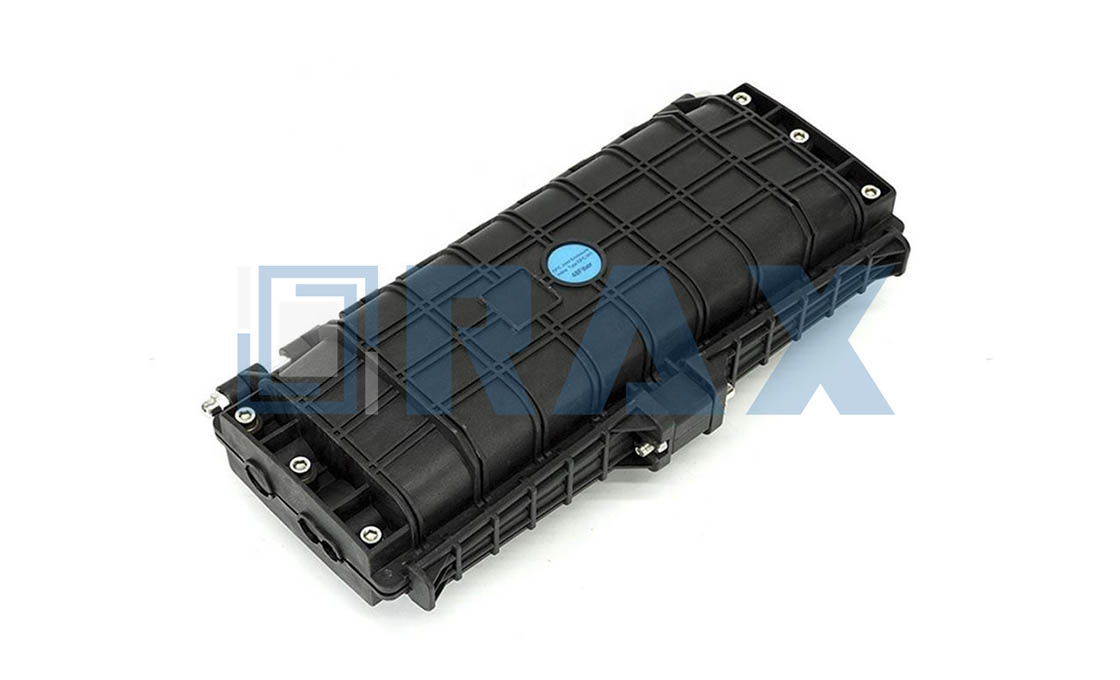

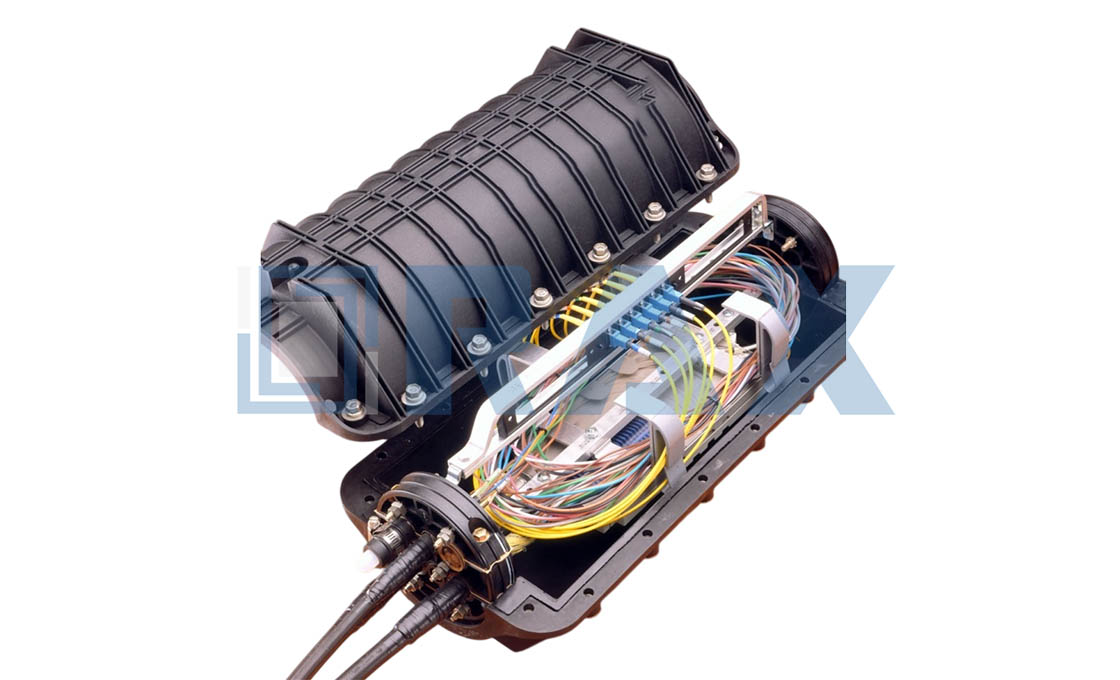

The Cross Connect Closure facilitates splicing and termination of multiple fiber optic cables in outside plant networks, providing environmental protection for reliable interconnection points. It supports high fiber counts with splicing capacity up to 96 single fiber splices and cross connect capabilities for 48 pigtails on both office and distribution sides.

Constructed from durable ultraviolet (UV) stabilized material, the closure features an internal bulkhead accepting various connector styles and multiple cable entries through each end plate. It safely stores uncut buffer tubes of feeder cables while providing individual connectivity to drop cable fibers. The LOCK-TAPE™ Sealant System achieves waterproof and airtight integrity without requiring costly re-entry kits.

The modular design accommodates cable diameters from 0.093 to 1.25 inches and supports configurations up to 144 fibers in low or deep profile arrangements. Features include isolated ground studs for simplified troubleshooting and strength member tie-off. Testing per Bellcore GR-771-CORE ensures mechanical stability and resistance to temperature fluctuations, moisture, and physical impacts.

Integrated splice trays organize fibers to minimize stress and prevent damage during installation. Multiple sealing options guarantee protection against water and dust ingress, complying with industry standards. The design supports versatile deployment in aerial, underground, pole-mounted, or wall-mounted applications for streamlined maintenance access.

Cross Connect Closure Wholesaler with Over 21 Years of Experience

RaxPower provides fiber optic connectivity solutions for every segment of the network, including Cross Connect Closure for FTTH and other applications. As a worldwide designer, manufacturer, and supplier with over 21 years of experience, we specialize in delivering high-quality, reliable products at reasonable prices.

Our Cross Connect Closure ensures efficient fiber terminations, splicing, and distribution, built to withstand harsh environmental conditions with features like high intensity and anti-erosion performance.

Guided by the Toyota TPS culture, we achieve high quality, short delivery time, and low cost through advanced manufacturing processes such as hot forging and automation, coupled with strict quality control measures like load testing and multi-stage inspections.

Why choose RaxPower? We leverage our extensive production capabilities, including 17,000 square meters of workshops and a dedicated team, to offer factory-direct prices, customized solutions, and responsive service.

Click send inquiry to get best offer and free sample now.

| Parameter | Value |

|---|---|

| Product Type | Cross Connect Closure |

| Closure Shape | Dome |

| Splicing Type | Single Fusion |

| Splice Capacity | Up to 96 single fiber splices |

| Cross Connect Capacity | Up to 48 pigtails on both office and distribution sides |

| Maximum Fiber Count | Up to 144 fibers |

| Splice Tray Type | Low Profile, Deep Profile |

| Number of Splice Trays | 10 |

| Maximum Cable Diameter | 0.093 to 1.25 inches |

| Cable Ports | 4 |

| Drop Port Style | Flat Drop Cable Entry |

| Dimensions | 8.6 inches diameter, 17.9 inches length |

| Material | Durable UV stabilized material |

| Internal Bulkhead | Accepts a variety of connector styles |

| End Plate | Multiple cable entries through each end plate |

| Sealing System | LOCK-TAPE™ Sealant System |

| Grounding | Isolated ground studs |

| Testing Standard | Bellcore GR-771-CORE |

Frequently Asked Questions (FAQS)

What is a cross connect closure used for?

A cross connect closure is designed for applications requiring connectorization or cross connecting in the outside plant network. It allows for convenient and safe storage of uncut buffer tubes in the feeder cable while providing individual connectivity to the fibers of the drop cables. It is used in various environments, including central office settings and remote field locations, supporting both aerial and underground cable deployments.

How does the closure ensure compliance with industry standards?

The closure is tested in accordance with Bellcore GR-771-CORE, ensuring it meets rigorous standards for performance and durability in outdoor plant networks. It typically achieves high ingress protection ratings (e.g., IP68) to prevent water and dust ingress, providing assurance of reliability and adherence to industry requirements critical for applications demanding extreme product dependability.

What materials is the closure made from and how does it withstand harsh conditions?

The closure is constructed from durable, UV-stabilized materials such as industrial plastic or high-grade metal, designed to be waterproof and airtight. It withstands environmental stresses including temperature fluctuations, moisture, dust, and physical impact, ensuring long-term integrity in demanding outdoor settings from aerial to underground deployments.

Are there any hidden costs for re-entry or ongoing maintenance?

No costly re-entry kit is needed. The closure features a revolutionary LOCK-TAPE™ Sealant System and neoprene gasket that allow for repeated access without additional expenses. Multiple sealing options, including mechanical seals, enable the closure to be opened and resealed multiple times while maintaining waterproof and airtight integrity, saving on maintenance costs and supporting efficient project budgeting.

How is the closure installed?

Installation involves securing the closure to a mounting structure, preparing the cables for entry, and managing fiber routing within the internal splicing area. The closure features multiple entry end plates for flexible cable management, safe storage of uncut buffer tubes, and isolated ground studs that simplify troubleshooting and strength member tie-off. It includes options for pole mounting, wall mounting, aerial hanging, or underground placement, facilitating efficient installation and reducing downtime for field technicians.

How many fibers can the closure splice and cross connect?

The closure can splice up to 96 single fiber splices and cross connect up to 48 pigtails on both the office and distribution side. Some models support splicing capacities like 144 low profile or 80 deep profile single fusion, with configurations accommodating specific fiber counts such as 24, 96, or 144 cores.

What types of connectors does the closure support?

The internal bulkhead is designed to accept a variety of connector styles, including ST, SC, and FC. Kits may come half-loaded or fully-loaded with specific connectors, such as FC-PC, and the closure accommodates both single-mode and multimode fiber cables for versatile applications.

Get A Quick Quotation Today