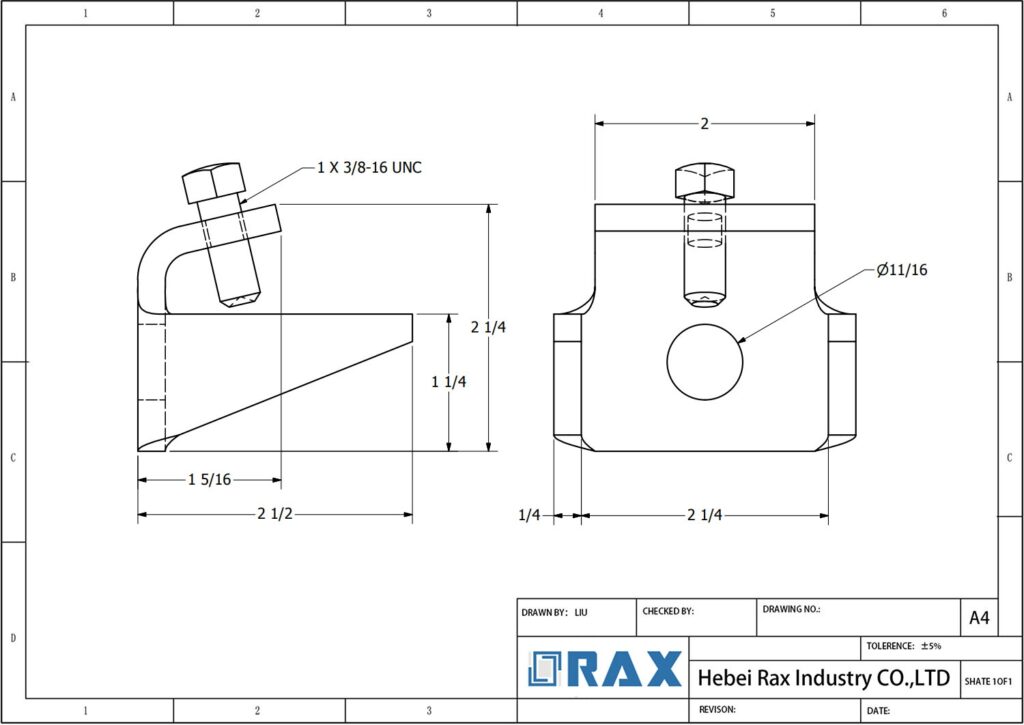

The B Beam Clamp dead-ends strand runs to I-beams in structural and communications applications without permanent beam alterations. It anchors strands in communication line installations and creates fast connections between steel beams with parallel flanges, handling moderate tensile loads in construction, telecommunications, and infrastructure projects.

The clamp features an adjustable mechanism with a set screw for positioning on the beam flange, eliminating drilling or welding requirements. Its flat top allows the bolt head or nut to rotate on a hardened washer. Independently evaluated for fatigue resistance and approved for dynamic load applications, the high-strength design reduces on-site hazards by avoiding hot work permits. A skirt on the underside prevents rotation during installation.

Constructed from malleable iron or steel with hot dip galvanized finish per American Society for Testing and Materials (ASTM) A153, the clamp provides corrosion protection and durability. Attachment holes accommodate 5/8-inch or 11/16-inch bolts, and the clamp handles beam flanges across various thicknesses. Certain configurations support tensile loads up to 17,720 pounds. Adjustable tail lengths (short, medium, long) and packing pieces extend the clamping range for specific flange thicknesses.

The B Beam Clamp complies with ASTM A153 for galvanization, Telcordia GR-3174-CORE for communications hardware, and EN 1993-1-9 for dynamic loads. Installation involves positioning with the clamping screw and tightening—no drilling or welding needed. Product datasheets recommend using location plates or end plates when securing opposing clamps.

B Beam Clamp Manufacturer

RaxPower, established in 2003 and based in Hebei Province, China, brings over 21 years of manufacturing expertise to the B Beam Clamp, a secure and adjustable solution for attaching lifting equipment without welding or drilling. Utilizing advanced processes like hot forging, which enhances strength and accuracy, our clamp is designed for easy installation and robust grip, ensuring maximum safety and load stability during lifting operations.

With 17,000 square meters of production workshops, 5,000 square meters of warehouses, and a team of over 170 professionals including engineers and quality supervisors, we implement strict quality control through raw material selection and multi-stage testing.

Compatible with beam flanges from 3.0 to 8¼ inches, manually adjustable for a precise fit, and featuring screw-down adjustment for secure placement, it is ideal for single-person use with a capacity of 310 lbs. Suitable for applications such as bridge work, steel structure anchorage, and connection points for vertical lifelines, the B Beam Clamp delivers reliable performance under heavy loads and complies with ANSI, OSHA, and CSA standards.

Choose RaxPower for quality-engineered beam clamps that reflect our philosophy of maximum safety and reliability.

| Parameter | Value |

|---|---|

| General Specifications | |

| Product Type | B Beam Clamp |

| Application | Dead-ending strand runs to I-beams in structural and communications applications |

| Attachment Hole Sizes | 5/8-inch or 11/16-inch bolts |

| Clamping Mechanism | 3/8-inch x 1-inch set screw or clamping screw for initial positioning |

| Mechanical Properties | |

| Tensile Load Capacity | Up to 17,720 pounds (in four-bolt configuration) |

| Fatigue Resistance | Independently evaluated per EN 1993-1-9 |

| Dynamic Load Approval | Independently approved per EN 1993-1-9 |

| Materials & Finish | |

| Material | Malleable iron or steel |

| Finish | Hot dip galvanized per ASTM A153 |

| Corrosion Protection | Suitable for various environmental conditions; enhances durability |

| Standards & Approvals | |

| Galvanization Standard | ASTM A153 |

| Communications Standard | Telcordia GR-3174-CORE |

| Dynamic Load Standard | EN 1993-1-9 |

| Installation Features | |

| Installation Method | No drilling or welding required |

| Adjustability | Available in short, medium, and long tail lengths; packing pieces for extended clamping range |

| Rotation Prevention | Skirt on underside abuts beam flange edge |

| Bolt Head/Nut Compatibility | Flat top allows rotation on hardened washer |

| Additional Notes | |

| Customization | Use of location plates or end plates for specific configurations (e.g., opposing clamps or supporting sections only) |

| Key Benefits | Time-saving and labor-saving installation; avoids hot work permits; high-strength construction for safer connections |

Related Products

Frequently Asked Questions (FAQS)

What is the B Beam Clamp designed for?

The B Beam Clamp is used for dead-ending strand runs to I-beams in power distribution, telecommunications, and structural applications.

How is the B Beam Clamp installed?

The clamp features a clamping screw for initially positioning on the beam flange and a 3/8 x 1 set screw for positioning during attachment. The attachment hole accommodates standard bolts such as 5/8

What material and corrosion protection does the B Beam Clamp have?

The clamp is made from galvanized steel and hot dip galvanized following ISO 1461 procedures to meet ASTM Specification A153, ensuring a mean coating thickness of more than 85 microns for superior corrosion protection in harsh outdoor environments.

Which industry standards does the B Beam Clamp comply with?

It meets RUS/UL listing standards and complies with Telcordia GR-3174-CORE specification, making it suitable for communications infrastructure and power utility applications.

Get A Quick Quotation Today