Fiber optic cable hardware includes accessories and components that support the installation, management, and performance of fiber optic systems. This hardware serves various cable types such as All-Dielectric Self-Supporting (ADSS) and Optical Ground Wire (OPGW) cables, which are essential for aerial and ground-based optical communication networks. The components facilitate proper deployment and maintenance of fiber infrastructure across diverse environments.

The hardware delivers high performance, reliability, and scalability for consistent data transmission in demanding conditions. Components feature easy installation and durability, withstanding environmental stressors like moisture, corrosion, UV exposure, and extreme temperatures. This rugged construction enhances dependability and reduces long-term maintenance requirements.

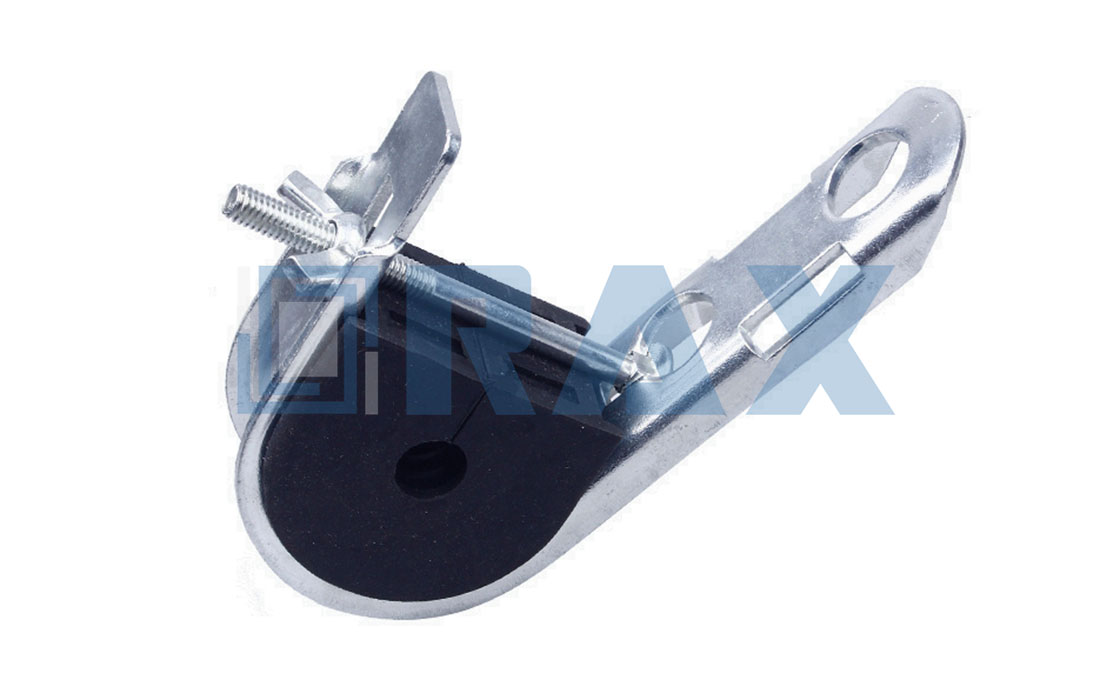

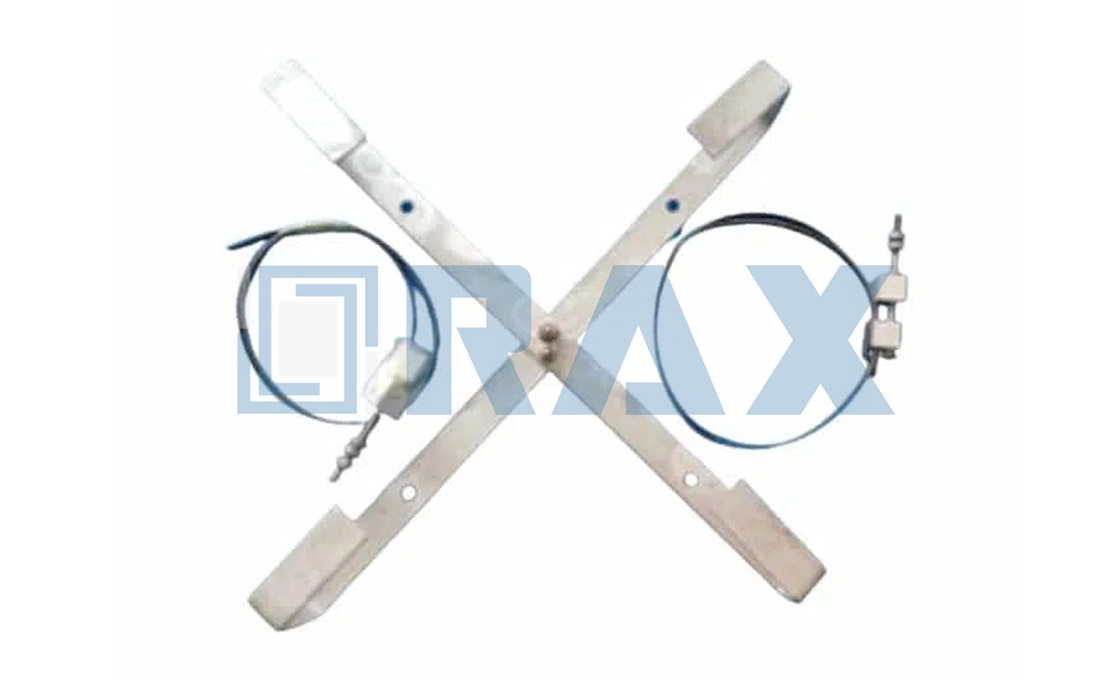

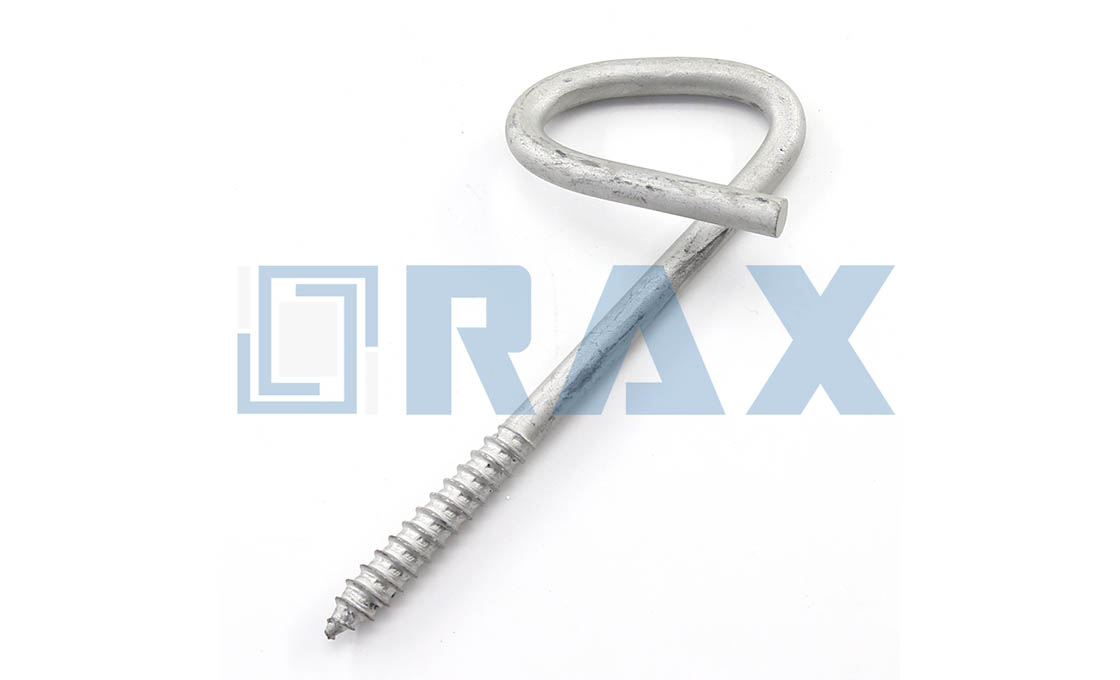

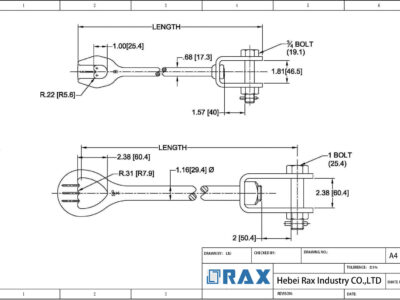

Product categories include hardware for ADSS, OPGW, and SkyWrap cables, along with connectors, adapters, closures, and fiber management systems. Pre-terminated assemblies streamline deployment for both indoor and outdoor applications. Solutions like the Base-16 Fiber Cabling System utilize 16 fibers per jacket and terminate with MPO or duplex LC connectors for parallel applications. Fiber optic panels, cassettes, and enclosures use corrosion-resistant materials for environmental protection.

Applications span data centers, industrial settings, telecommunications, and harsh environments including aerial installations, underground conduits, and direct burial situations. The hardware supports Fiber to the Home (FTTx) networks, warehouse automation, and power transmission lines, providing high-speed communication and sensing capabilities where resistance to mechanical impact and extreme conditions is required.

Leading Fiber Optic Cable Hardware Manufacturer

RaxPower stands out as a leading manufacturer in the fiber optic cable hardware industry. With over 21 years of experience since our establishment in 2003, we operate from a state-of-the-art facility in Hebei Province, China, spanning 17,000 square meters of production workshops.

We leverage cutting-edge technology and advanced manufacturing processes, including hot forging and automatic machines, to ensure optimal production speeds and unwavering product quality. Our extensive portfolio features intelligent, innovative, and individualized cable solutions, such as ADSS and OPGW accessories, designed to meet diverse customer needs with precision, durability, and reliability.

Emphasizing quality at the highest level, every fiber optic cable hardware component undergoes strict quality control, from raw material selection to multi-stage testing, ensuring performance in demanding environments. TELL US ABOUT YOUR PROJECT and let’s collaborate to bring your vision to life with high-performance, tailored solutions.

Other Products You May Like

Frequently Asked Questions (FAQS)

What types of fiber optic cable hardware are available?

A complete portfolio of supporting hardware and compression accessories is available, including options for all-dielectric self-supporting (ADSS) aerial cables and Optical Ground Wire (OPGW), designed for transmission and distribution networks in utilities and telecommunications.

Are the hardware products suitable for outdoor use?

Yes, the hardware is designed for aerial installation in outdoor transmission and distribution environments, ensuring reliability in harsh conditions.

How do I select the appropriate hardware for my fiber optic cable installation?

Selection depends on the cable type (ADSS or OPGW) and application requirements. RaxPower offers guidance and utilizes advanced engineering systems for automatic hardware selection, specifications generation, design calculations, and project cost estimates to streamline planning for large-scale installations.

How is the hardware installed?

Installation involves using the supporting hardware and compression accessories for mounting on poles or towers, designed for easy and secure aerial installation of fiber optic cables.

What support services are offered to ensure proper installation and operation?

RaxPower provides comprehensive support services, from classroom training to on-site field installation assistance, ensuring customers are supported through all stages of design and construction for optimal deployment and operational efficiency.

How does RaxPower ensure product reliability and quality?

RaxPower leverages years of manufacturing experience with rigorous quality control processes including load testing and gauge checks. Design expertise focuses on optimizing hardware for enhanced reliability and durability, ensuring consistent performance that meets industry standards across diverse applications and demanding environments.

Get A Quick Quotation Today