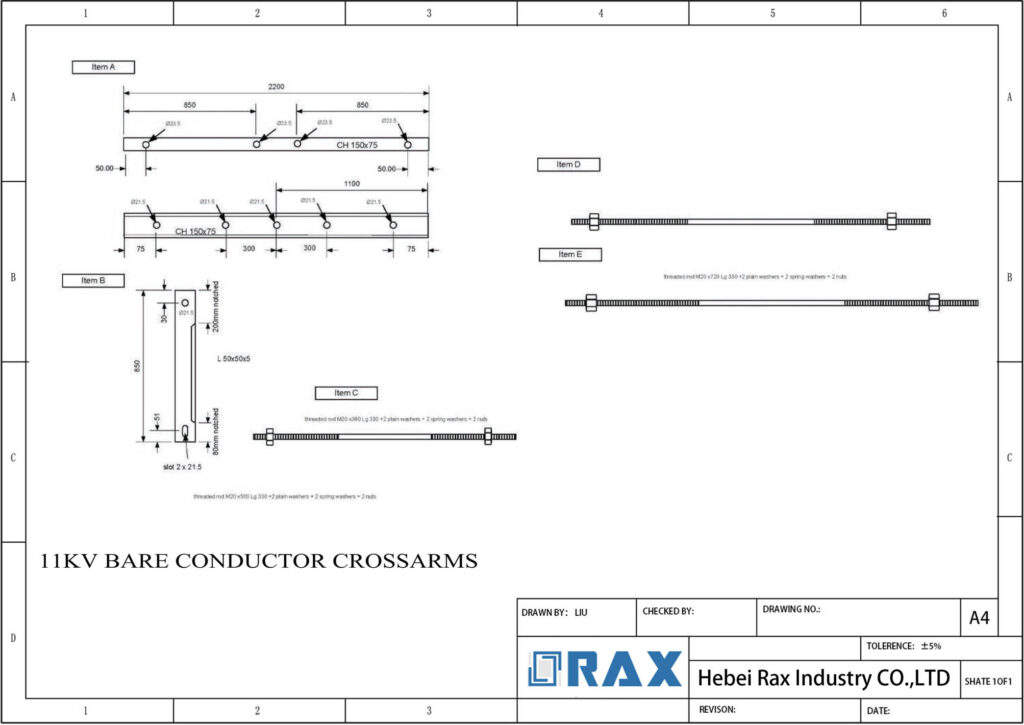

Power Pole Cross Arms are horizontal beams attached to utility poles that support and space conductors, insulators, and hardware in overhead electrical systems. These components maintain proper clearance between lines and ensure structural stability for power transmission and distribution networks.

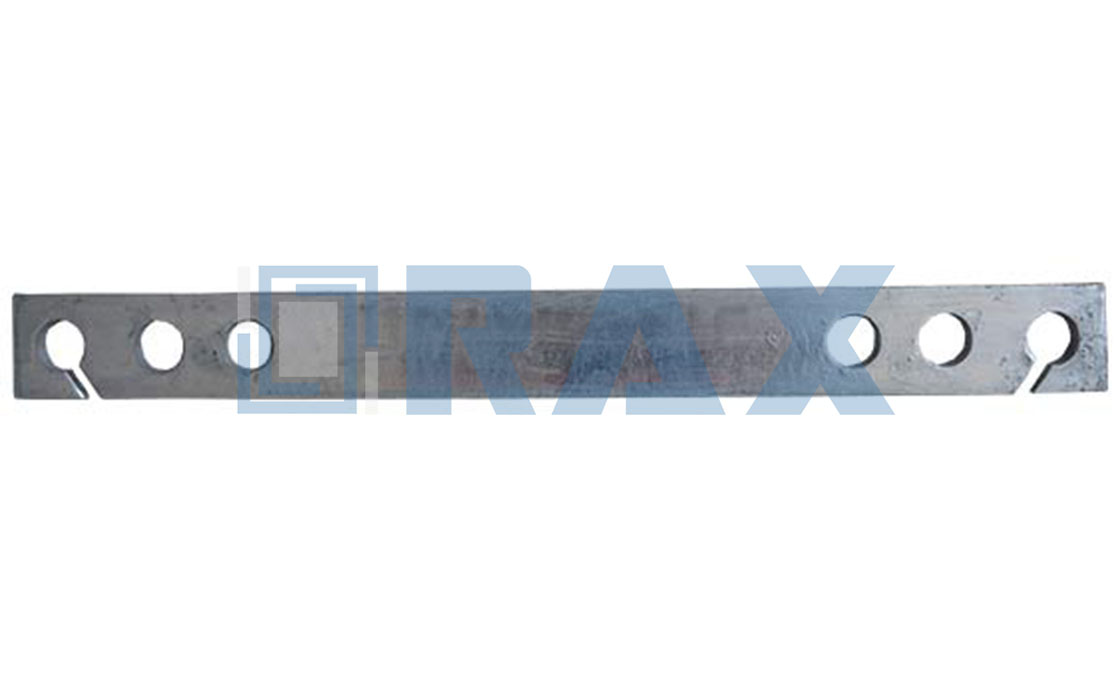

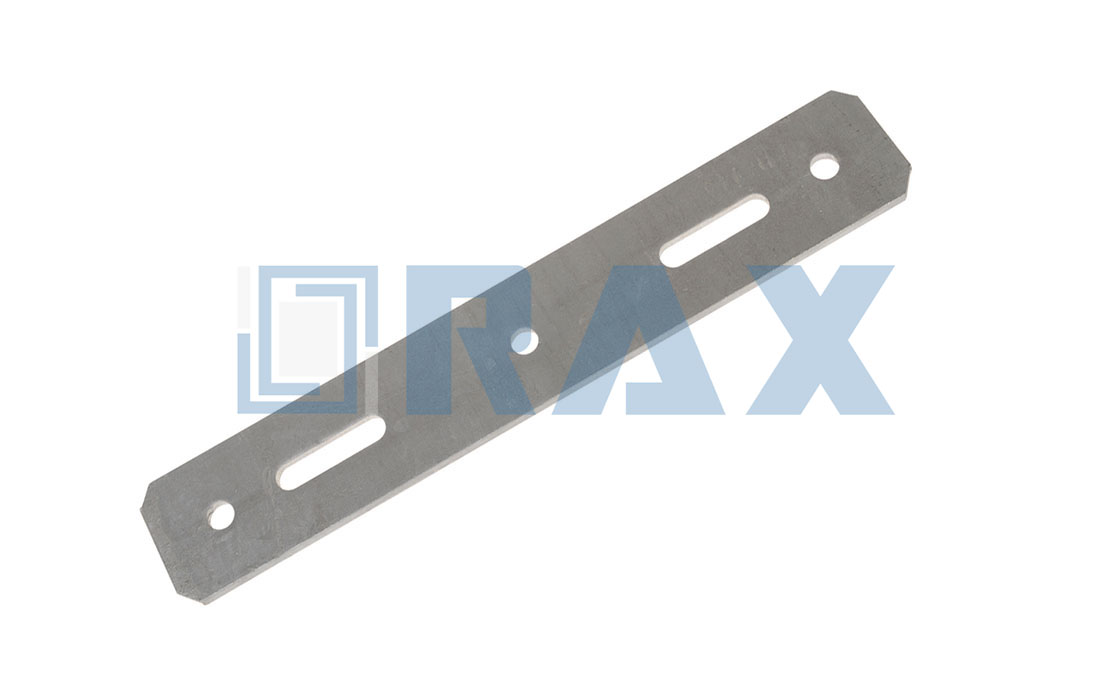

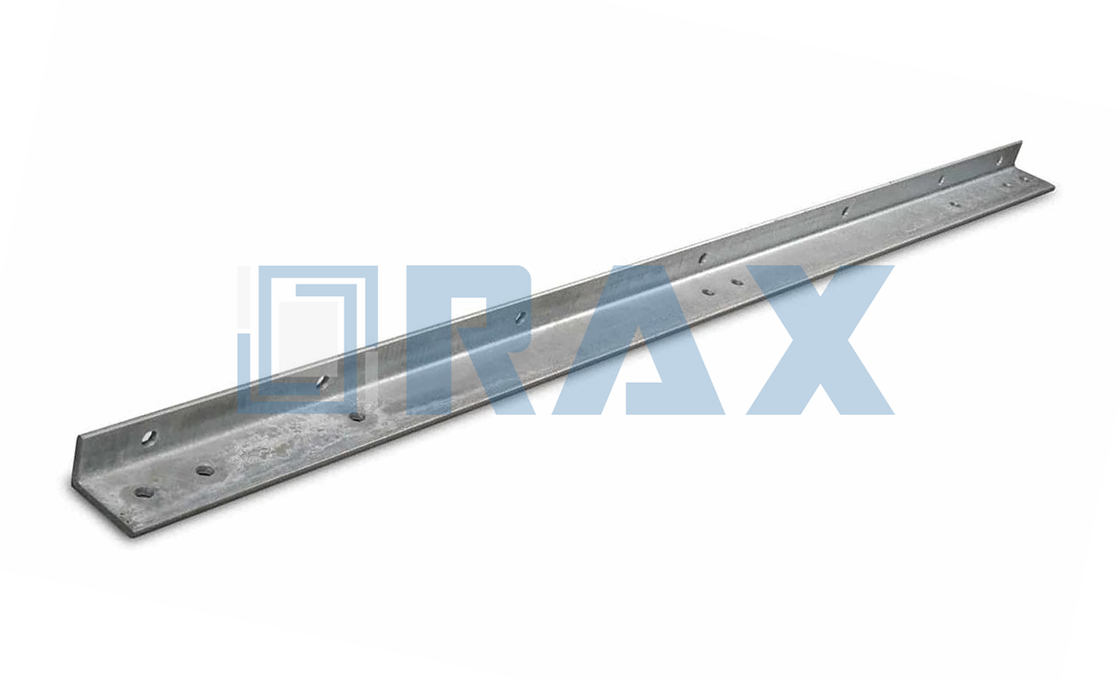

Cross arms are constructed from wood, steel, or composite materials including fiberglass. Steel cross arms are typically hot-dip galvanized for corrosion resistance, while wood options may be pressure-treated. Composite materials provide lightweight alternatives with enhanced resistance to environmental factors. Manufacturing involves automated drilling and cutting to create precise, burr-free holes, with dimensions ranging from 500mm to over 6000mm depending on application requirements.

Performance specifications include tensile strength adequate to withstand mechanical loads, wind forces, and ice accumulation. Designs comply with industry standards such as American National Standards Institute (ANSI) O5.3, ensuring structural integrity under dynamic stress conditions. Installation requires mounting the cross arm to the pole using specialized fasteners like pigtail bolts, U bolts, and double arming bolts, with proper alignment and conductor tensioning verified before completion.

Regular maintenance includes inspections for cracks, corrosion, or wear, typically conducted annually or following severe weather events. Selection considerations encompass material type, load requirements, environmental conditions, and regulatory compliance to ensure long-term reliability and safety in electrical infrastructure.

Trusted Power Pole Cross Arm Expertise from RaxPower Wholesaler

RaxPower stands out as a leader in the power pole cross arm industry because of our innovation, experience, and longevity. With over 21 years of expertise since our establishment in 2003, we have built a reputation for reliability and customer focus. Our cross arms are engineered for long-term performance, ensuring consistent power transmission and grid stability.

LONGEVITY

The elements don’t stand a chance with RaxPower. Our hot-dip galvanized coating, with a mean thickness exceeding 85 microns, provides durable protection against corrosion, locking out moisture and contaminants for decades of service.

DURABILITY

RaxPower cross arms are built to last using advanced hot forging technology, resulting in greater strength and accurate sizing. They withstand harsh environmental conditions and transient loads, with rigorous load testing ensuring reliability under stress.

RELIABILITY

You can count on our products for consistent quality. Automated manufacturing processes ensure uniformity, with gauge tests according to IEC 120 standards and SGS certification for peace of mind.

CUSTOMER FOCUS

We prioritize your needs with quick response times and reliable delivery, backed by our extensive experience and dedicated support team.

Contact us for a quick inquiry to enhance your power infrastructure with RaxPower.

| Particulars | Cross-arm Dimensions (mm) | Application | Material | Tensile Strength (kN) |

|---|---|---|---|---|

| Single Member Intermediate | 120x53x6.3mm-2500mm | Used at single member intermediate structures with a span of 80-100m. | Hot-dip galvanized steel | |

| Two Member Intermediate | 120x53x6.3mm-3000mm | Used at two member intermediate structures with a span of 100-180m. | Hot-dip galvanized steel | |

| Two Member Straight Section | 150x100x10mm-3000mm | Used at two member section structures with a span of 100-180m. | Hot-dip galvanized steel | |

| Two Member Angle Section | 150x100x10mm-3000mm | Two of these are used at two member angle section structures with a span of 100-180m. | Hot-dip galvanized steel | |

| Two Member Tee-off | 150x100x10mm-3000mm | Used at the lay pole of the tee-off structure. | Hot-dip galvanized steel | |

| Two Member Transformer | 150x100x10mm-3000mm | Used for terminal and pilot cross-arms. | Hot-dip galvanized steel | |

| Two Member Structure | 150x100x10mm-3000mm | Used at Auto-recloser and LBS/ABS structures. | Hot-dip galvanized steel | |

| Two Member Switchgear | 150x100x10mm-3000mm | Used at the terminal structure of the line. | Hot-dip galvanized steel | |

| Three Member Terminal | 200x150x15mm-6000mm,70kN | Used at 3-member structures with a span of 180-250m. | Hot-dip galvanized steel | 70 |

| Three Member Straight Section | 200x150x15mm-6000mm,70kN | Used at 3-member structures with a span of 250-300m. | Hot-dip galvanized steel | 70 |

| Three Member Angle Section | 250x200x15mm-9000mm,100kN | Used for 3-member structures with a span greater than 300m. | Hot-dip galvanized steel | 100 |

Frequently Asked Questions (FAQS)

What is a power pole cross arm?

A power pole cross arm is an engineered component used in pole line technology to support power lines and electrical equipment. It holds insulators and conductors, ensuring proper spacing and stability for reliable power transmission and distribution.

What are the main types of power pole cross arms and their applications?

The main types include power pole cross arms for connecting conductors and insulators, line-cross arms for weight distribution in transmissions, side arms for single circuits, telephone pole cross arms for multiple connections, and light pole cross arms for supporting streetlights. Each type is designed for specific application requirements in power distribution, telecommunications, and lighting infrastructure.

What materials are used for cross arms and how does this affect performance?

Cross arms are typically made from wood, steel, and composites. Steel offers high tensile strength and is hot-dip galvanized for corrosion resistance and longevity. Composites provide lightweight durability and resilience. Material selection impacts strength, weather resistance, maintenance requirements, and overall system safety across different environmental conditions.

How is a power pole cross arm installed?

Installation involves attaching the cross arm to the utility pole using bolts such as double arming bolts, pigtail bolts, or U bolts, with cross arm braces for additional support. Conductors and insulators are then secured to the cross arm. The process requires expertise, safety gear, and proper alignment to ensure stability and adherence to international safety standards such as IEC and IEEE.

Why is regular maintenance important for power pole cross arms?

Regular maintenance through scheduled inspections identifies early signs of damage like cracks, rust, or wear. This prevents equipment failure, reduces safety hazards, and prolongs the lifespan of the power distribution system by addressing issues before they escalate.

How do you ensure cross arms meet reliability and safety standards?

Our cross arms undergo rigorous testing, including strength and corrosion resistance tests, and are manufactured to comply with international safety standards such as IEC and IEEE. We use automatic machines for precise hole sizes and uniform dimensions, maintain strict raw material selection with no recycled materials, and apply hot-dip galvanization for long-term durability in harsh environmental conditions.

Can you accommodate custom cross arm specifications for specialized projects?

Yes, our engineering team can customize cross arm solutions to meet specific application requirements for specialized projects including railway and telecommunication installations, ensuring optimal support and compatibility for your unique needs.

Get A Quick Quotation Today