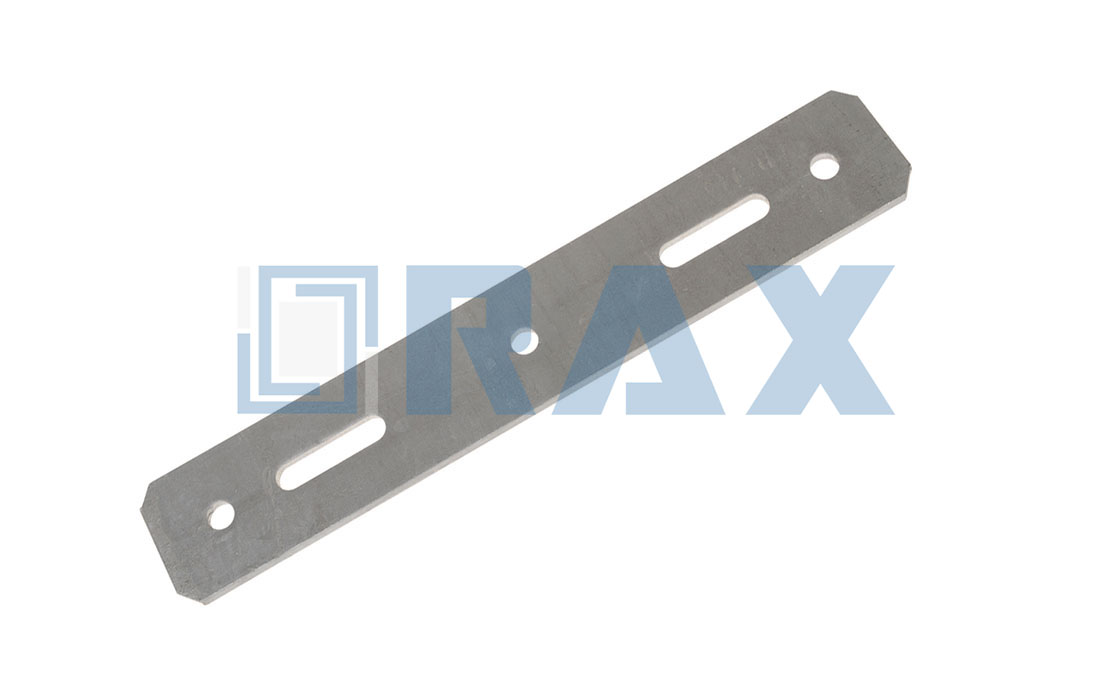

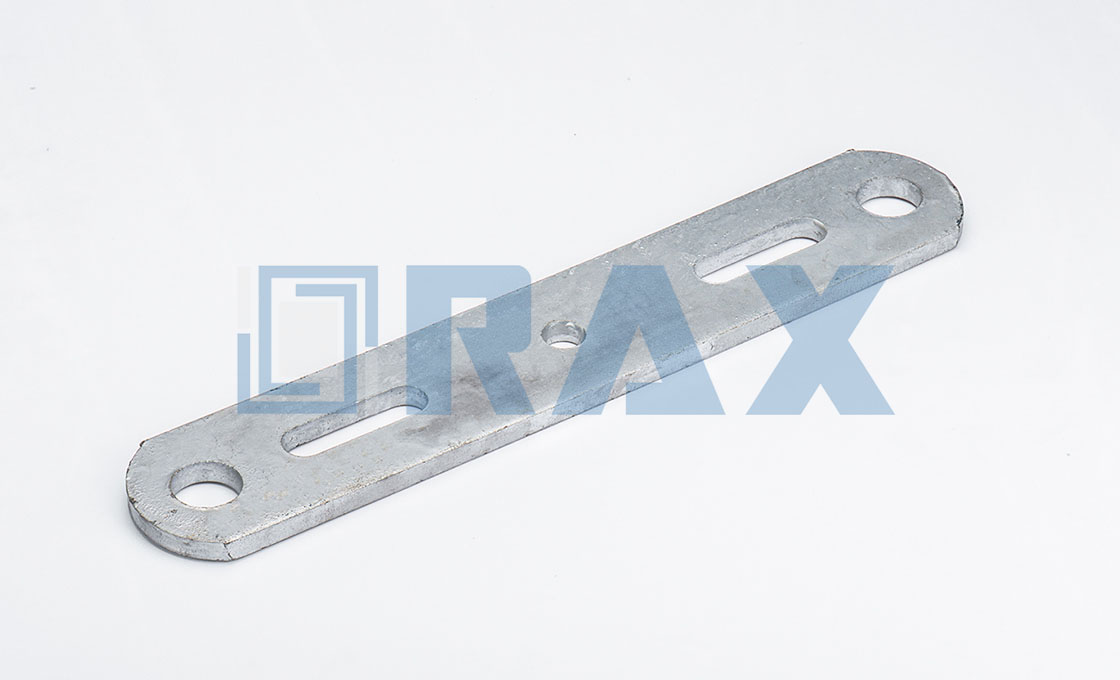

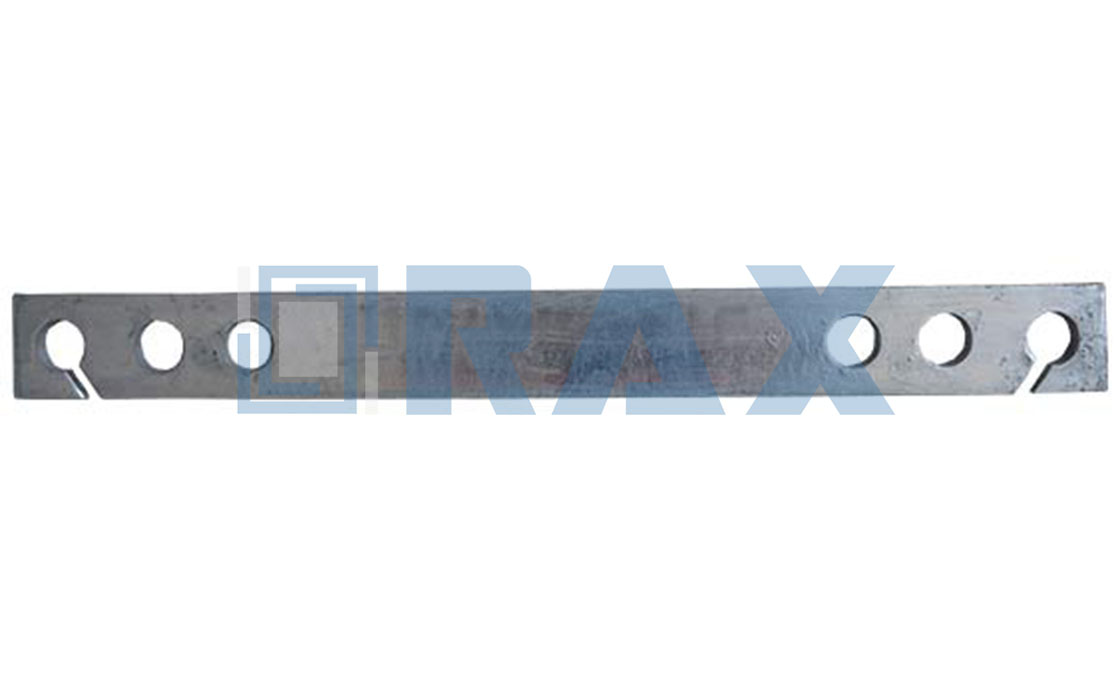

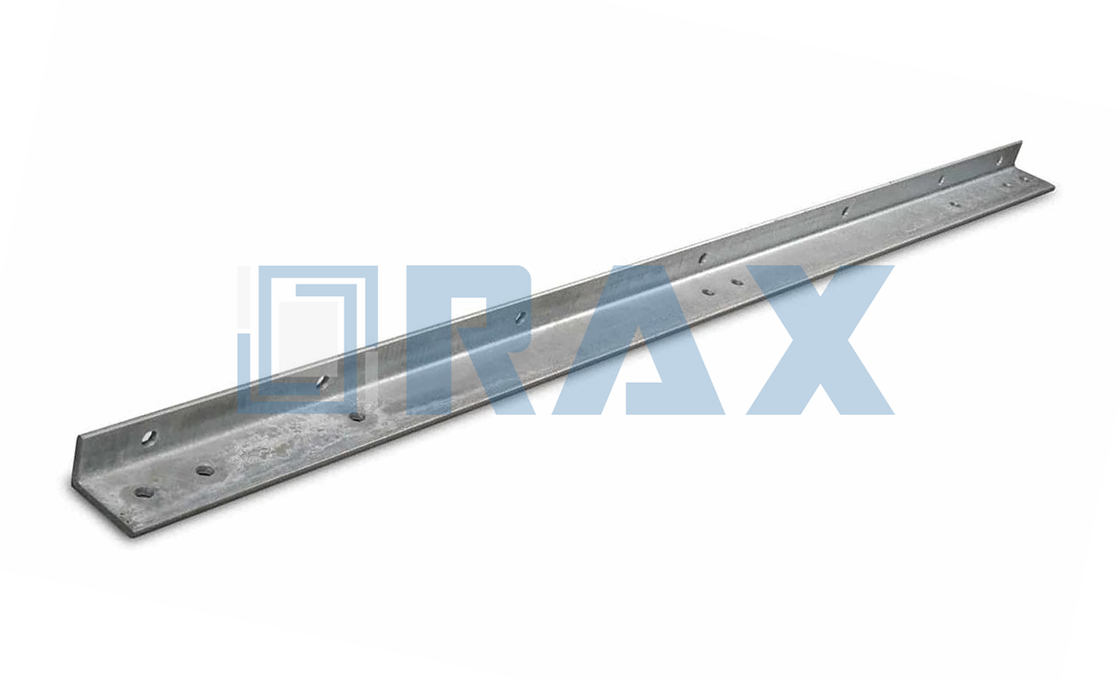

The Double Arming Plate supports and secures two crossarms on a single utility pole in power distribution systems, particularly in double-arm construction common in Russia and similar regions. This reinforcing plate enhances structural integrity and load-bearing capacity by providing dual arm support that minimizes crossarm movement and shifting during installation and operation.

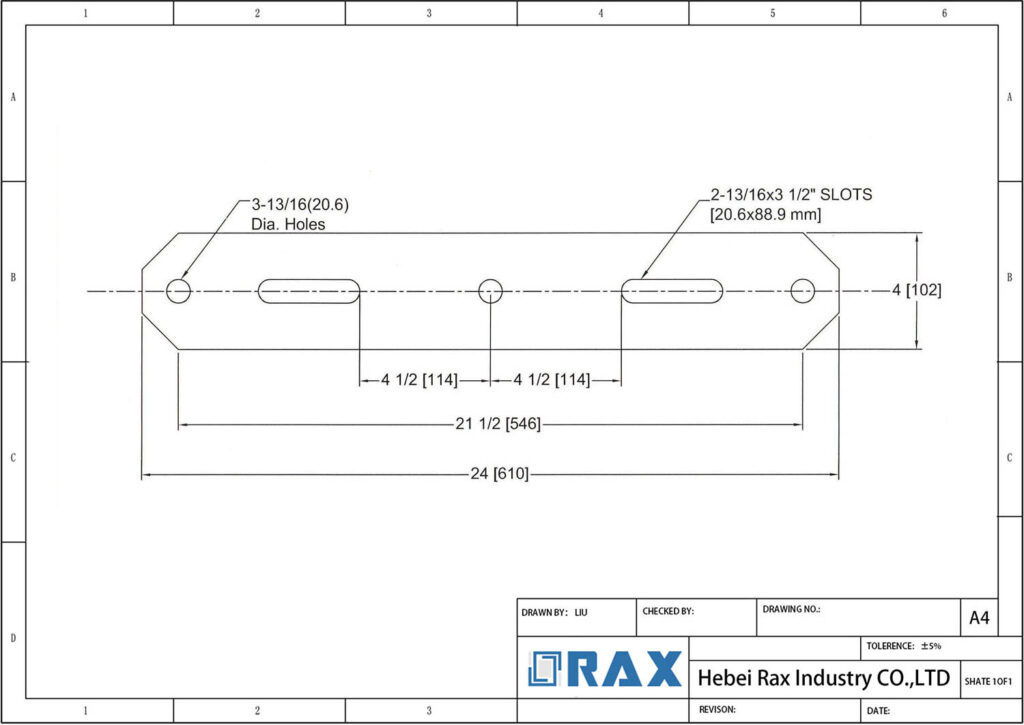

Constructed from carbon steel or high-strength steel (with aluminum options available), the plate undergoes hot-dip galvanizing per ASTM A-153 standards for corrosion resistance and extended service life. The design includes pre-drilled mounting slots (typically 11/16″ x 3-1/2″ or 13/16″ x 3-1/2″) and center holes for insulator pins or deadend connections. Standard dimensions range from 4 inches in width and 17 to 24 inches in length, with approximately 0.5-inch thickness.

The heavy-duty construction distributes loads evenly across the pole assembly, reducing structural failure risk while the galvanized coating protects against environmental degradation. The plate installs easily with standard tools, reducing labor time, and can be customized to accommodate specific pole and crossarm sizes with tolerances ensuring field compatibility.

The product meets ISO 9001 quality management standards and carries Rural Utilities Service (RUS) listing for utility applications, ensuring compliance with industry requirements for electrical infrastructure reliability and safety.

Double Arming Plate Manufacturer

As trusted utility pole hardware supplier, RaxPower delivers excellence to meet your project needs. Established in 2003 and located in Hebei Province, China, we bring 21 years of manufacturing and exporting experience to every Double Arming Plate we produce. This crucial component for double-arm construction ensures reliable support for electrical infrastructure by connecting two parallel cross arms and securing insulator pins at the center hole. Key features include:

- Hot-dip galvanized coating for superior corrosion resistance, with mean coating thickness over 85 microns per ISO 1461.

- Precision-engineered using automatic machines and hot forging technology for accurate sizing and enhanced strength.

- Customizable in all sizes through our OEM/ODM services, tailored to your specific design requirements.

Our rigorous manufacturing process begins with advanced CAD design and selection of high-strength steel, followed by precision cutting, drilling, and controlled hot-dip galvanization. Multi-stage quality control, including load testing and gauge checks per IEC standards, ensures every plate meets the highest performance and durability standards. With over 170 employees and 17,000 square meters of production facilities, we are dedicated to delivering products that embody our philosophy of quality and reliability.

At RaxPower, we not only supply industry-standard components but also provide flexible solutions for projects of any scale. Let’s talk about your next project! Whether you have detailed drawings or just a concept, we’re ready to listen.

| Stock No. | Steel Size (Width x Thickness) | Length (in) | Mounting Hole Hole (in) | Mounting Hole Slot (in) | Weight (kg/100 pcs) | Package Qty | Material | Coating | Coating Standard | Quality Standard | Certifications | Unit Weight (lb) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D0400-01 | 4 x 1/2 | 24 | 13/16 | 13/16 x 3-1/2 | 563.00 | 5 | Carbon steel or high-strength steel | Hot-dip galvanized | ASTM A-153 | ISO 9001 | RUS listed | 12.4 |

| D0400-02 | 4 x 1/2 | 17 | 13/16 | 11/16 x 3-1/2 | 210.00 | 10 | Carbon steel or high-strength steel | Hot-dip galvanized | ASTM A-153 | ISO 9001 | RUS listed | 4.6 |

Frequently Asked Questions (FAQS)

What is a Double Arming Plate and what is its primary function?

RaxPower's Double Arming Plate is a crucial component in power distribution systems that supports and secures two crossarms on the same pole. It serves as a connecting element between the crossarms and the pole, enhancing structural integrity and load-bearing capacity while providing a mounting position for insulator pins or deadend connections.

What materials and corrosion protection are used in Double Arming Plates?

Double Arming Plates are constructed from robust materials such as steel, carbon steel, or malleable iron for durability and long-term performance. They are hot-dip galvanized per ASTM A-153 and ISO 1461 standards, providing superior corrosion resistance that ensures longevity and reliability even in harsh environmental conditions while reducing maintenance needs.

What are the standard dimensions and mounting specifications?

Standard dimensions include widths like 4 inches and lengths such as 17 inches or 24 inches, with variations available. They feature precision-punched mounting holes, including slots (e.g., 11/16 x 3-1/2) and connection holes (e.g., 13/16), designed to fit poles with top diameters from 8-12 inches and gains 0.5 inch deep for secure installation.

How are Double Arming Plates installed on utility poles?

Installation is straightforward and designed for use with standard tools to reduce labor time. The plates are secured to the pole and crossarms through pre-drilled holes and slots, ensuring a stable platform for attaching insulator pins and facilitating efficient assembly in double-arm construction.

Can you customize Double Arming Plates to our specific project requirements?

Yes, RaxPower offers comprehensive OEM/ODM services to customize double arming plates according to your specific drawings and application needs. We can produce all sizes and tailor designs to unique pole profiles, load requirements, and installation needs, ensuring perfect fit, compatibility, and optimal performance for your infrastructure projects.

What quality control measures ensure compliance with industry standards?

RaxPower implements strict quality control processes, including raw material selection, load testing, and verification of galvanization standards. Our products comply with relevant certifications, and we provide third-party test reports to verify compliance, durability, safety, and performance standards.

How do you manage lead times and order quantities for different project scales?

RaxPower accommodates orders of any size with no minimum order quantity for samples. We offer flexible lead times, typically 5-7 working days for prototypes, and efficiently handle bulk orders through automated production and extensive warehousing facilities, ensuring on-time delivery for both small and large-scale projects.

What after-sales services and warranties do you provide?

We provide a 2-year warranty on all double arming plates and offer dedicated after-sales support, including installation guidance and freight solutions. Our team is available to assist with any issues to ensure optimal performance and customer peace of mind throughout the product lifecycle.

Get A Quick Quotation Today