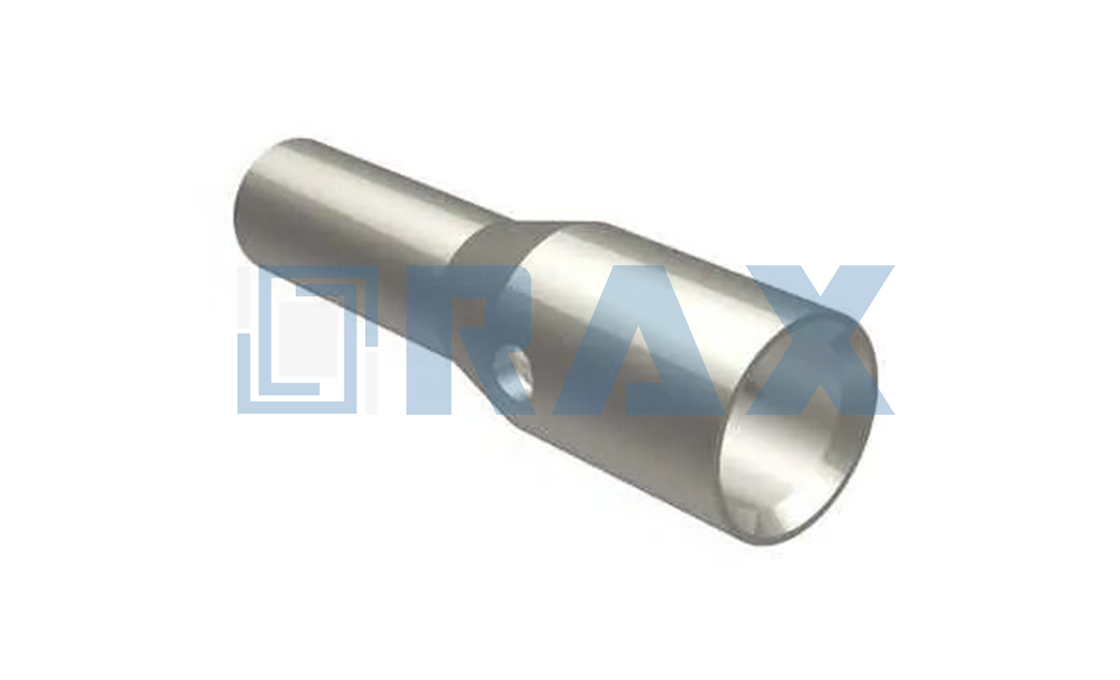

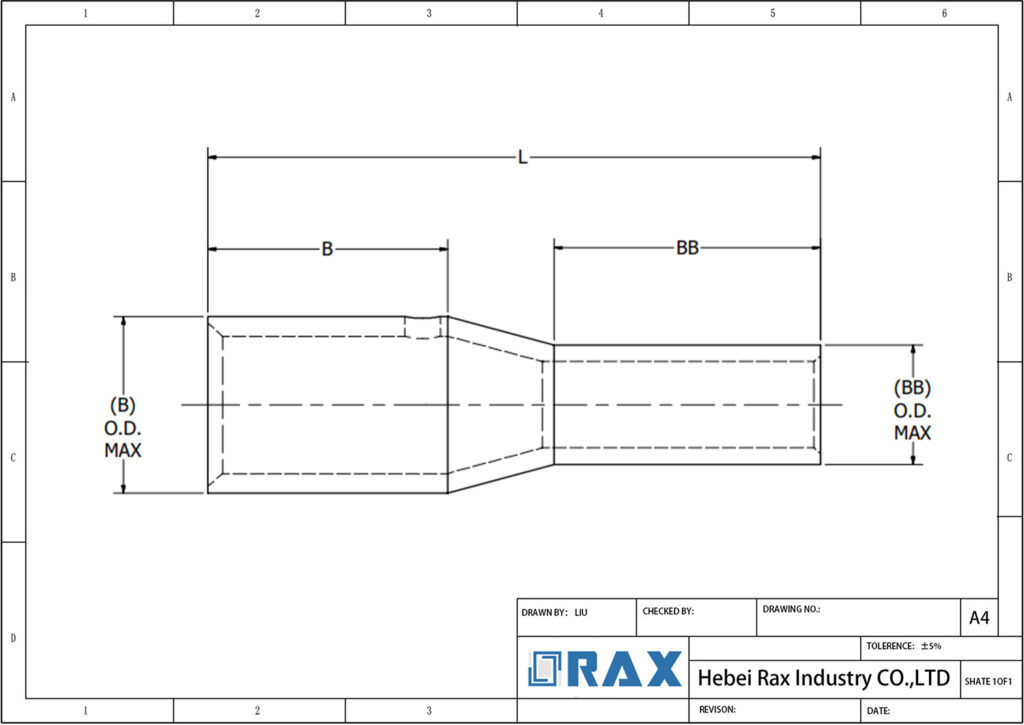

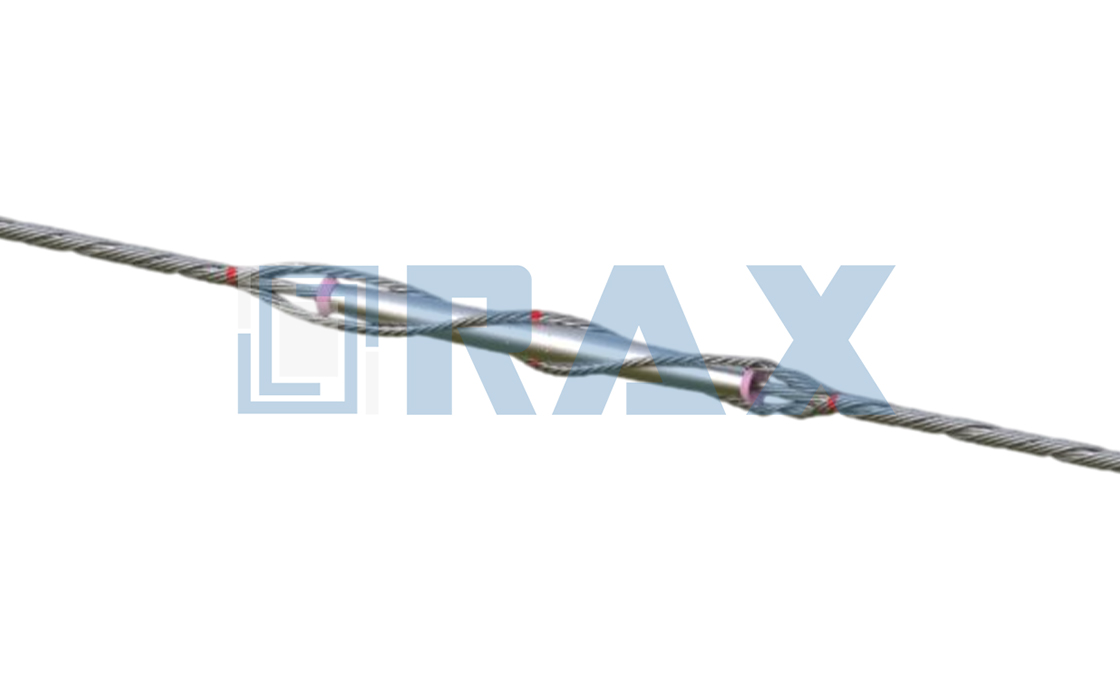

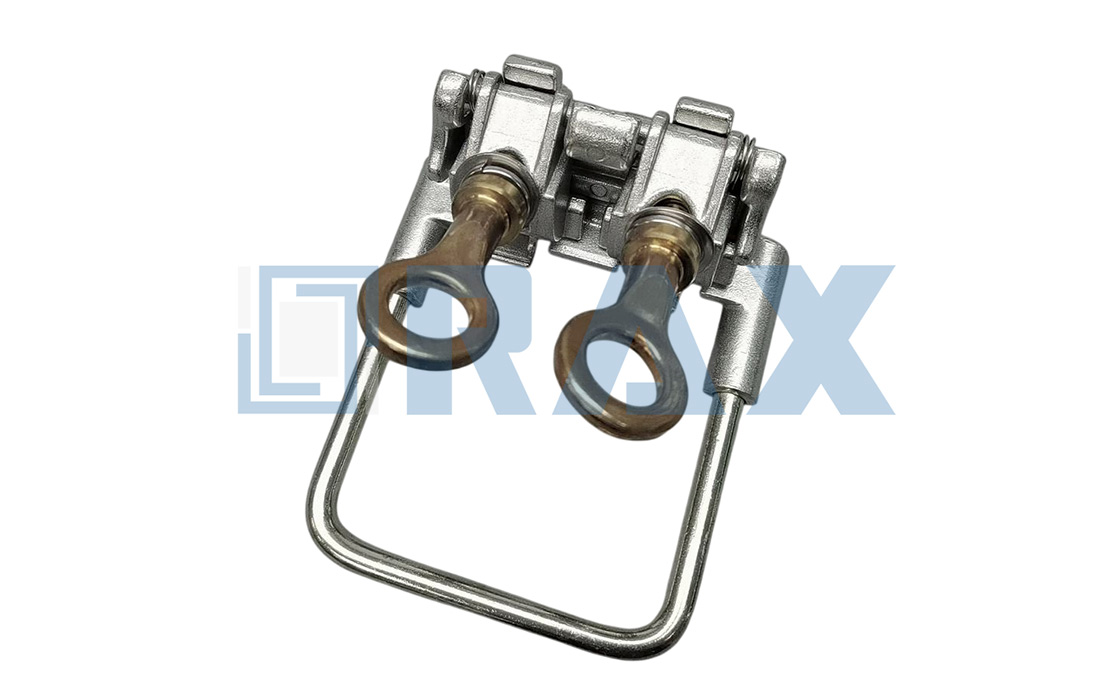

Reducing splices permanently join two conductors of different diameters through compression without requiring tools for hand application. Built from high conductivity seamless copper tubing with tin plating to inhibit corrosion, these connectors ensure optimal conductivity and environmental resistance. Dual-rated models accommodate both aluminum and copper conductors and may be factory pre-filled with oxide inhibitor such as PENETROX™ to prevent galvanic corrosion.

Design features include inspection windows in each barrel to verify full cable insertion and chamfered barrel entries for smooth wire insertion without strand damage. Color-coded end caps and barrels display conductor gauge sizes and die index numbers for proper identification, while crimp location bands enable precise tool application. The splices facilitate spinner-free travel without gate adjustments or lifting requirements, maintaining compatibility with strand material.

Certifications include cULus Listing per UL486A-B for power applications and UL467 for grounding, bonding, and direct burial. Models may meet UL224 VW1 flame resistance standards and pass abrasion and cut tests per TELCORDIA GR-347-CORE. Tooling compatibility extends to Penn-Union, Burndy, Thomas & Betts (T&B), Huskie, Greenlee, and Versa-Crimp compression tools as confirmed by cULus listings, ensuring reliable crimping in field applications.

Reducing Splice Manufacturer

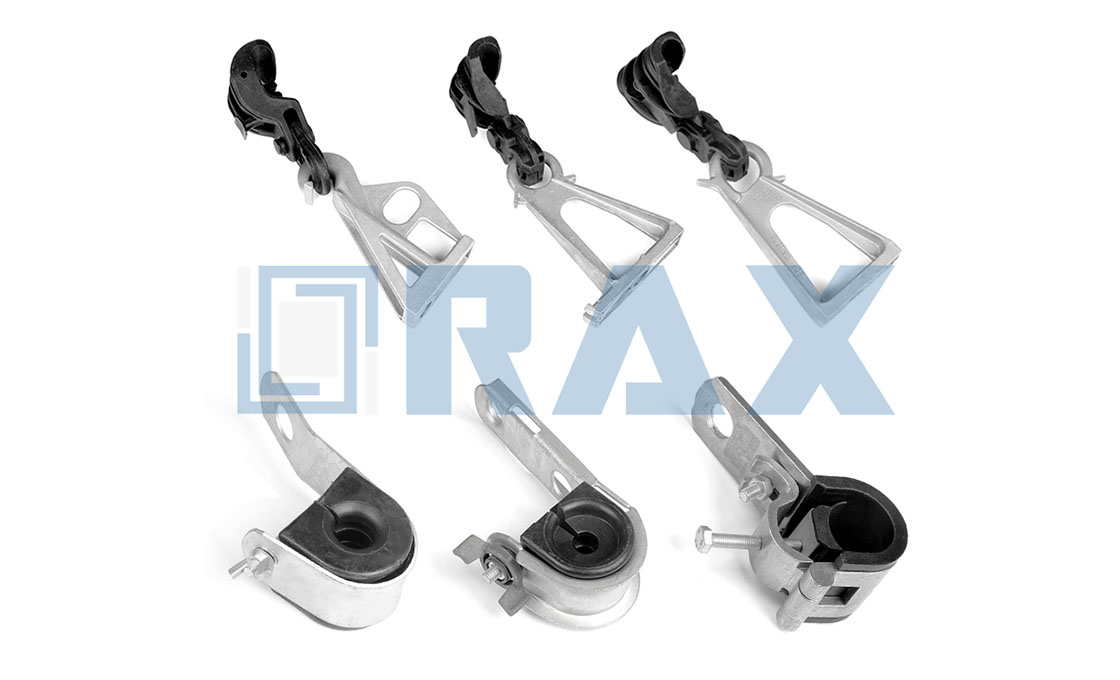

Here is a glimpse of RaxPower’s Solutions for the different Markets. Established in 2003 and located in Hebei Province, China, RaxPower has over 21 years of manufacturing and exporting experience, with 17,000 square meters of production workshops and 5,000 square meters of warehouses.

As a full-service market solutions provider, we deliver versatile and adaptive products for a wide range of applications:

- data center

- mining

- OEM

- oil & gas

- power generation

- solar

- telecom

- transportation

- utility

- wind

Our Reducing Splice is constructed from pure electrolytic copper tubing for optimal conductivity and tin plated to resist corrosion, ensuring reliable performance in splicing two different size wires.

Utilizing advanced processes like hot forging for greater strength and accurate sizing, and backed by strict quality control with raw material selection and multi-stage testing, we ensure every Reducing Splice meets the highest standards for durability and efficiency.

With a team of over 170 employees, including professional technicians and engineers, RaxPower is your trusted partner for high-quality electrical components. Add To Cart now or contact our experts for personalized consultation and support.

| Parameter | Specification |

|---|---|

| General | |

| Product Type | Reducing Splice |

| Color Code | Yes, marked with conductor gauge sizes and die index numbers |

| Die Index | Yes, as marked on barrels |

| Material | High conductivity seamless copper tubing, tin plated |

| Finish | Tin plated |

| Temperature Rating | 90°C |

| Conductor Compatibility | |

| Conductor Material | Dual rated for aluminum and copper conductors |

| Oxide Inhibitor | Factory pre-filled with PENETROX™ |

| Conductor Size Range | Varies by model (e.g., Barrel A: 600 kcmil, Barrel B: 500 kcmil) |

| Physical Features | |

| Inspection Windows | Yes, in each barrel |

| Barrel Style | Chamfered entries |

| Crimp Location Bands | Yes |

| Heat Shrink | Provided with UL224 VW1 listed heat shrink tubing |

| Electrical Ratings | |

| Voltage Rating | 35 kV |

| Dimensions (Representative) | |

| Length | 2-1/4 in |

| Outside Diameter | 1.46 in |

| Strip Length | 2-5/16 in |

| Certifications and Compliance | |

| Industry Standards | cULus Listed per UL486A-B, UL467, UL224 VW1; TELCORDIA GR-347-CORE |

| RoHS Compliance | Yes |

| Tool Compatibility | |

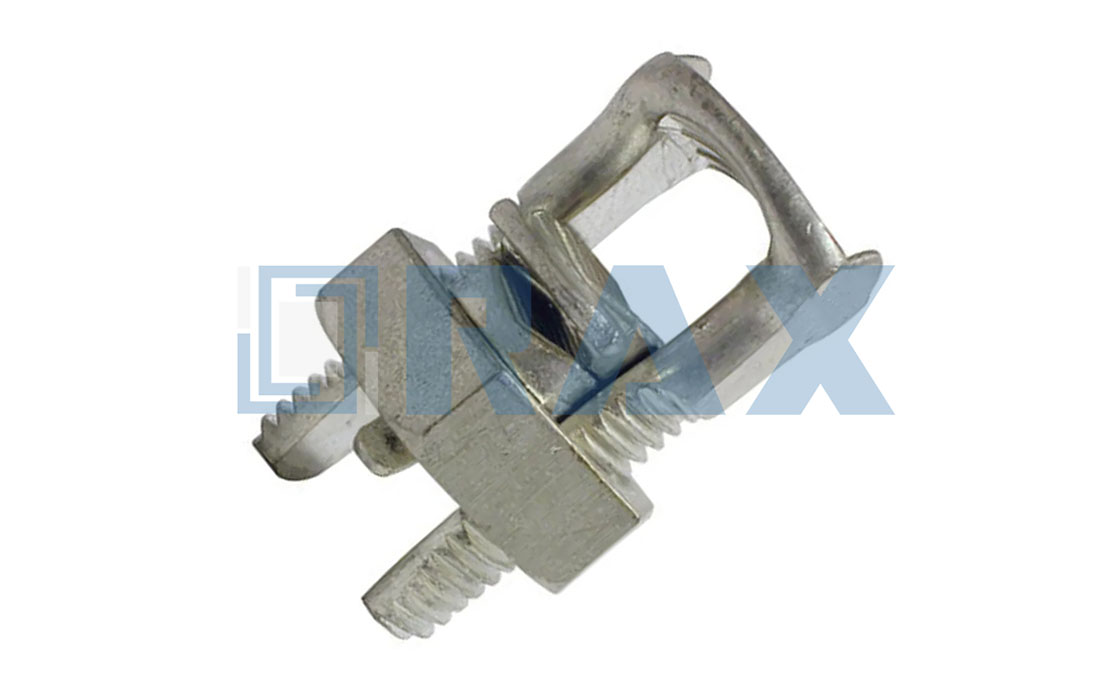

| Compatible Tooling | Penn-Union, Burndy, T&B, Huskie, Greenlee, Versa-Crimp |

| Installation | |

| Method | Larger conductor inserted first until it butts against center, followed by smaller conductor; no tools required for some models |

| Number of Crimps Required | 4 |

| Logistics | |

| Carton Quantity | 12 |

Frequently Asked Questions (FAQS)

What is the intended use of the reducing splice?

The reducing splice is intended to permanently join two strands of different diameters.

What are the advantages of using this reducing splice?

Advantages include easy hand application with no tools required, spinner-free travel design that permits passage without adjusting gates or lifting the spinner, material compatibility with both aluminum and copper conductors, hot-dip galvanized corrosion protection, and cULus Listed certification for power applications, grounding, bonding, and direct burial per UL 486A-486B standards.

How is the reducing splice installed?

It is quickly and easily applied by hand with no tools or specialized equipment required, making it efficient for field crews.

Can the same reducing splice be used for different conductor types?

Yes, the reducing splices are dual rated for both aluminum and copper wire, featuring an internal chamfer for smooth wire insertion and are prefilled with oxide inhibitor to ensure proper connections.

How do the reducing splices perform in harsh or corrosive environments?

The splices are made of material completely compatible with the strand and are hot-dip galvanized to inhibit corrosion, allowing them to be used in any environment with long-term durability.

Get A Quick Quotation Today