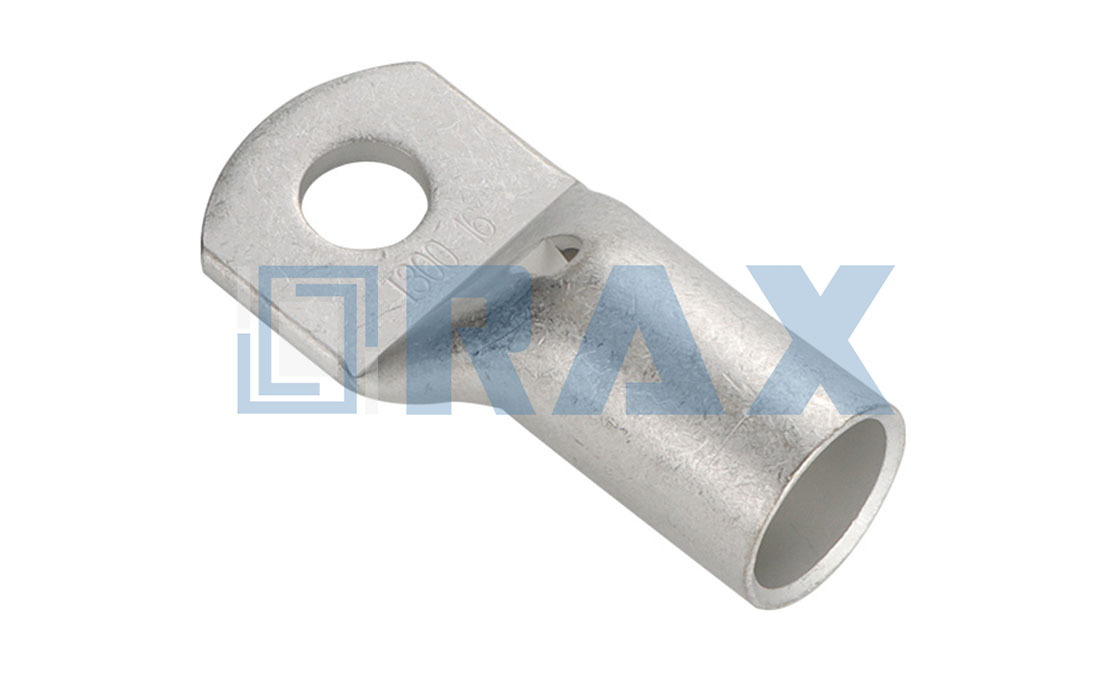

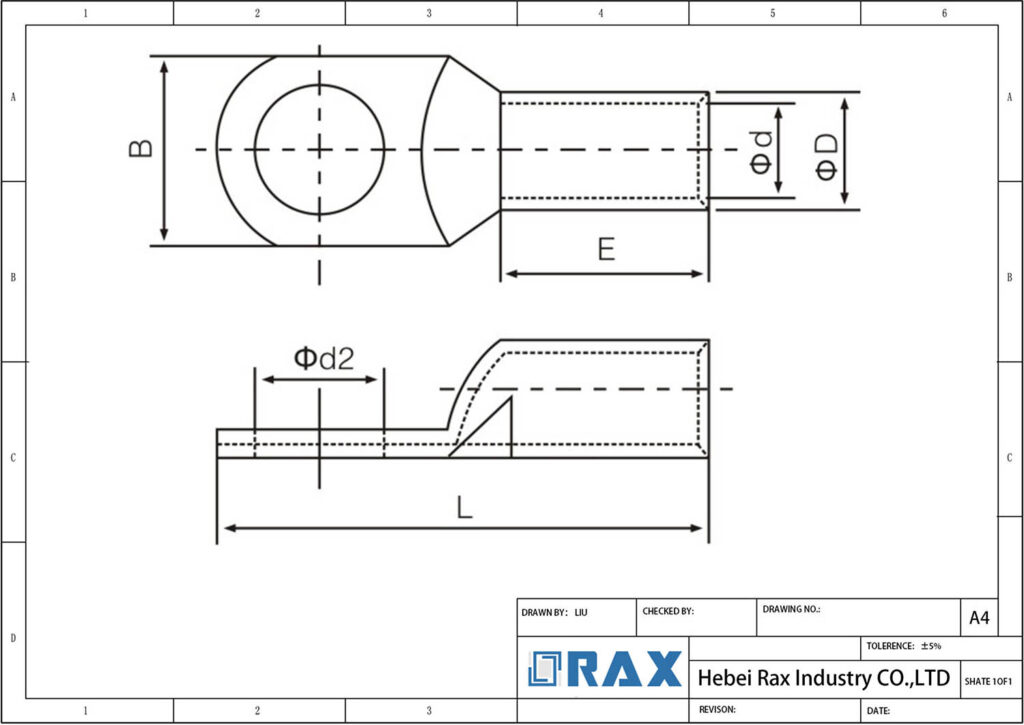

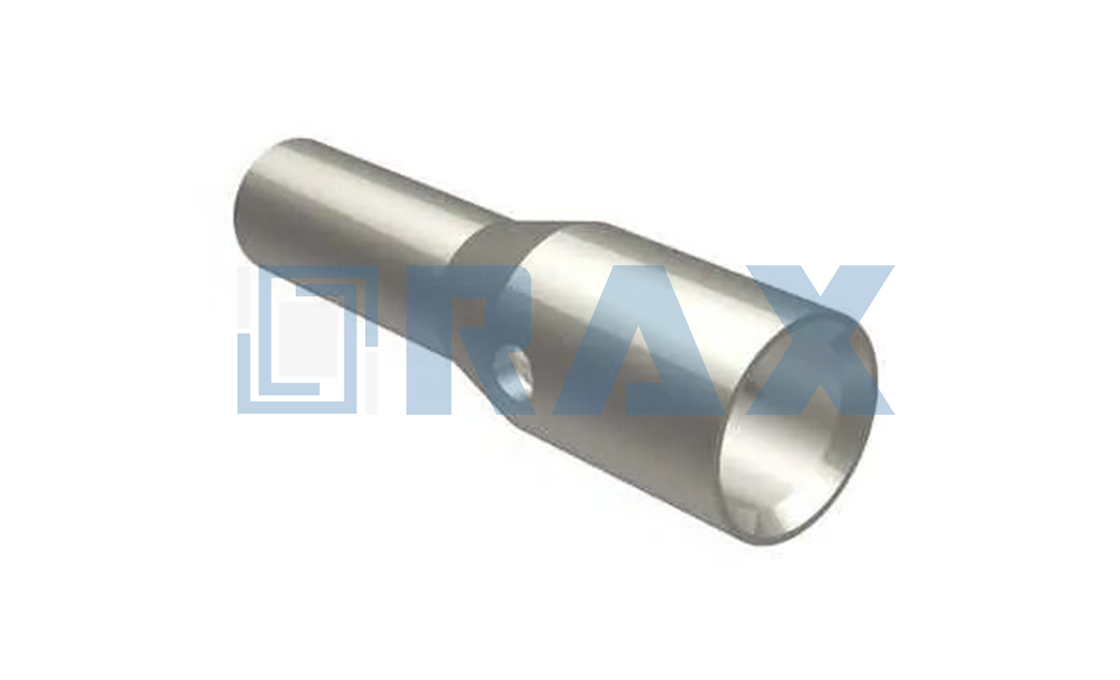

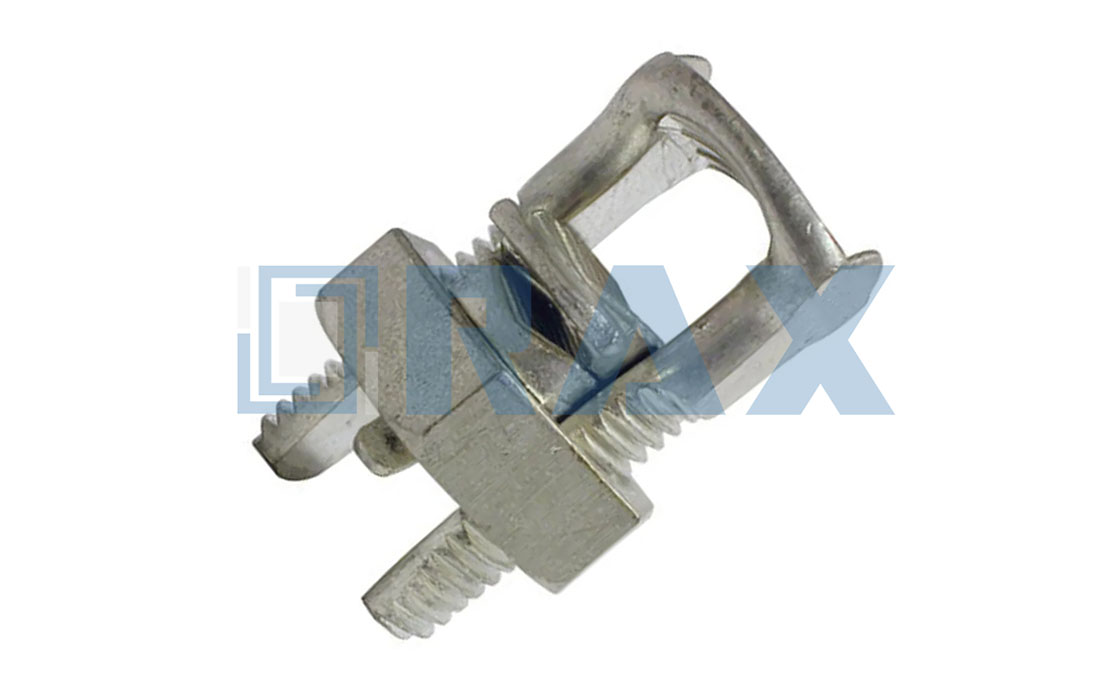

Compression lugs are electrical connectors manufactured from high-quality copper or aluminum, often with electro-tin plating to enhance performance. They accommodate cable sizes from 2 American Wire Gauge (AWG) to 3/0 AWG and are rated for voltages from 600 V to 35 kV, depending on proper installation and insulation techniques. The high-grade materials minimize resistance, reducing energy loss and improving system efficiency.

The durable construction offers resistance to corrosion, wear, and harsh environmental conditions, contributing to longevity in demanding settings. Precise dimensions and features like chamfered barrels or sight holes allow for secure fit, simplifying installation and reducing labor costs. This makes them cost-effective for applications ranging from small-scale projects to large industrial systems.

Compression lugs support flexible and stranded copper conductors, with stud sizes typically ranging from 1/4 inch to 1/2 inch. Barrel lengths are available in standard or long configurations, while tongue sizes and barrel diameters vary to match specific mounting requirements. Temperature ratings often reach 90 degrees Celsius, and color-coding or die indices enable easy identification during installation, ensuring compliance with industry standards for safety and performance.

Certified Compression Lug Wholesaler

It is the buyer’s responsibility to determine if the suggested replacement part is suitable for your application and intended use.

RaxPower, established in 2003 and located in Hebei Province, China, leverages 21 years of manufacturing and exporting experience to produce compression lugs that embody our commitment to quality and reliability.

Our lugs are manufactured from high conductivity copper tubing, tin-plated to ensure superior corrosion resistance and low contact resistance, utilizing advanced hot forging technology for greater strength and precise sizing.

Each lug is meticulously marked with die index and color coded for easy reference, and listed for 35KV maximum when properly installed according to cable manufacturer instructions, with a temperature rating of 90 degrees C.

Adhering to UL486A/B and UL467 certifications, our compression lugs undergo strict quality control measures, including raw material selection and multi-stage testing, supported by our 17,000 square meters of production workshops and automated processes for uniform accuracy.

This dedication ensures safety, compliance, and dependable performance in various conditions. For a comprehensive range of options and configurations, we encourage you to utilize our Configurator Tool.

| Parameter | Specification |

|---|---|

| Type | 1-Hole |

| Conductor Size | 2 AWG to 3/0 AWG |

| Conductor Type | Flexible and Stranded Copper |

| Stud Size | 1/4 in to 1/2 in |

| Barrel Type | Chamfered, Short, Standard |

| Barrel Length | Standard or Long |

| Barrel Dimensions (ID x OD x Length) | 0.484 in ID x 0.609 in OD x 0.75 in L |

| Overall Length | 2.064 in |

| Tongue Dimensions (Length x Width x Thickness) | 0.875 in L x 0.885 in W x 0.125 in THK |

| Mounting Hole Size | 0.281 in |

| Color | Orange |

| Material | Copper or Aluminum |

| Finish | Electro-tin plated |

| Voltage Rating | 600 V to 35 kV |

| Temperature Rating | 90°C |

| Die Code | ILD-50 |

| Standards | UL 486A/B, UL 467 |

Frequently Asked Questions (FAQS)

What are the key benefits of using compression lugs?

Compression lugs provide superior conductivity for minimal energy loss, durable construction resistant to corrosion and harsh environments, ease of installation with precise dimensions and color-coded die indices for secure connections, and versatility to accommodate cable sizes from 2 AWG to 4/0 AWG and beyond, including flexible copper conductors.

What materials are compression lugs made from?

They are typically made from high-quality copper or aluminum. Options include high-conductivity wrought copper that is electro-tin plated for enhanced corrosion resistance and low contact resistance.

What voltage ratings do compression lugs support?

Compression lugs are rated for voltages from 600 V up to 35 kV, depending on the model, and must be properly installed to meet these ratings in circuits. They meet standards such as UL 486A/B and UL 467, with temperature ratings of 90°C.

Get A Quick Quotation Today