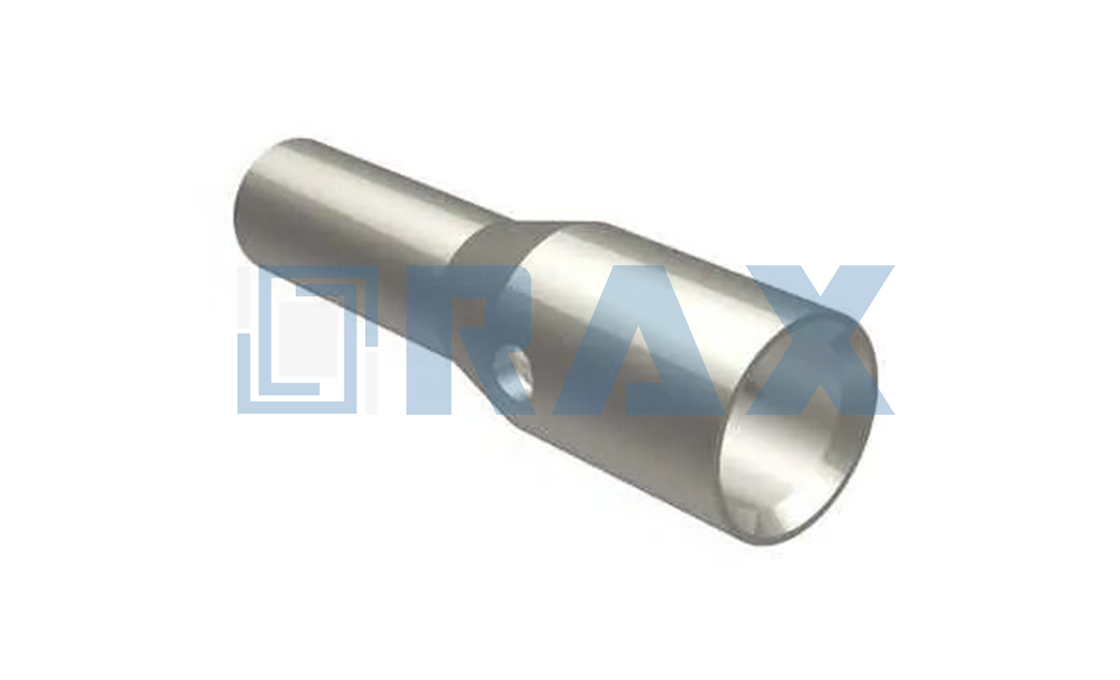

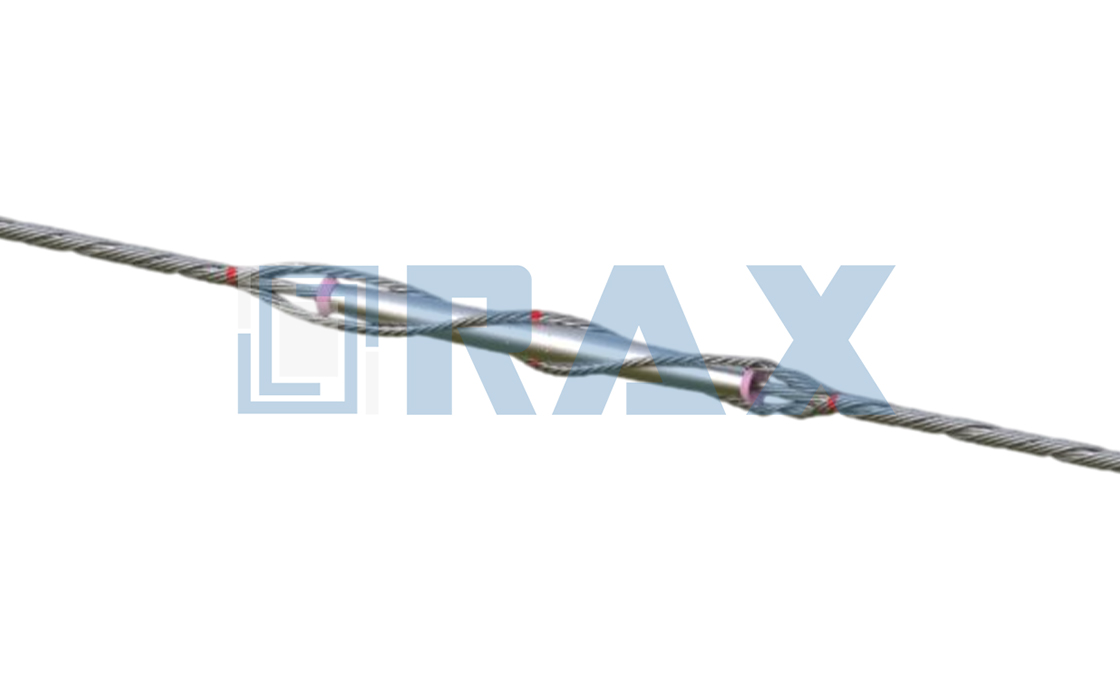

C-Tap Compression Connectors join wires in electrical contracting work through splicing or tapping into a continuous main. They enable pigtailing to connect existing wiring to new circuits, maintaining electrical flow during upgrades such as transitioning aluminum systems to copper where codes permit.

Made from high conductivity wrought copper with a plain finish, these connectors deliver efficient electrical performance. Their positive all-around compression creates low resistance and high pull-out values for secure connections. Heavy reinforcing ribs locate compression dies and strengthen the compressed joint, enhancing reliability.

The connectors accommodate American Wire Gauge (AWG) run conductors from 6 to 250 kcmil and tap conductors from 12 AWG to 250 kcmil, handling both solid and stranded types. A color-keyed compression system provides color-coded marks during crimping for easy identification. Compatible mechanical crimping tools feature ergonomic handles and color-coded die sets for precise installation.

Rated for voltages up to 600 volts (some variants to 35 kilovolts) and temperatures to 90 degrees Celsius, they meet Underwriters Laboratories (UL), Canadian Standards Association (CSA), Restriction of Hazardous Substances (RoHS), and Institute of Electrical and Electronics Engineers (IEEE) standards. Certain models support direct burial applications.

Boost Efficiency with RaxPower C-Tap Compression Connector Supplier

RaxPower C-Tap Compression Connector provides low resistance and excellent electrical conductivity. Featuring reinforced ribs that ensure maximum pull-out values and high strength, this connector is ideal for pigtailing, 2-way splicing, or tapping to an unbroken continuous main. Manufactured by RaxPower, a leading pole line hardware specialist in China with over 21 years of experience, the connector leverages advanced hot forging technology for superior durability and precise sizing. Constructed from high-conductivity copper, it withstands voltage ratings up to 600V – 35kV and temperature ratings of 90°C. Our commitment to quality, reliability, and environmental responsibility is demonstrated through strict quality control, including multi-stage testing, load tests, and RoHS compliance, with products passing SGS and authoritative institute certifications.

- Low resistance and excellent electrical conductivity for efficient performance

- Reinforced ribs provide high pull-out values and joint strength

- Suitable for pigtailing, splicing, and tapping applications

- High-conductivity copper construction ensures durability

- Voltage rating: 600V – 35kV; temperature rating: 90°C

- RoHS compliant and backed by rigorous quality assurance

| Parameter | Value |

|---|---|

| Material | High conductivity wrought copper |

| Run Conductor Size Range | 6 AWG to 250 kcmil |

| Tap Conductor Size Range | 12 AWG to 250 kcmil |

| Voltage Rating | Up to 600 V |

| Temperature Rating | 90°C |

| Finish | Unplated |

| Standards | UL, CSA, RoHS, IEEE |

| Dimensions (Length) | 1-11/16 in |

Frequently Asked Questions (FAQS)

What is a C-Tap compression connector used for?

C-Tap compression connectors are ideal for pigtailing, two-way splicing, or tapping to an unbroken continuous main in electrical contracting work. They join electrical wires, such as connecting a single wire to a strand of wires, and are commonly applied when upgrading or repairing wiring.

What are the key features and performance characteristics of C-Tap connectors?

Manufactured from high conductivity wrought copper, C-Tap connectors feature heavy reinforcing ribs that help locate compression dies and strengthen the compressed joint. This design ensures positive all-around compression with low resistance and high pull-out values for long-term durability and reliable electrical connections. Many models include color-keyed systems for easy identification.

What industry standards and certifications do C-Tap connectors meet?

C-Tap connectors are UL listed, CSA certified, and RoHS compliant. Many models also meet IEEE 837 standards, ensuring they adhere to rigorous safety and performance requirements for electrical applications.

What sizes are available for C-Tap connectors?

C-Tap connectors are available in a wide range of sizes for both run and tap conductors, including AWG sizes from 6 to 4/0 and kcmil ranges up to 500. Specific models accommodate various combinations, such as 8-6 AWG run with 12-8 AWG tap or 3/0 AWG to 250 kcmil.

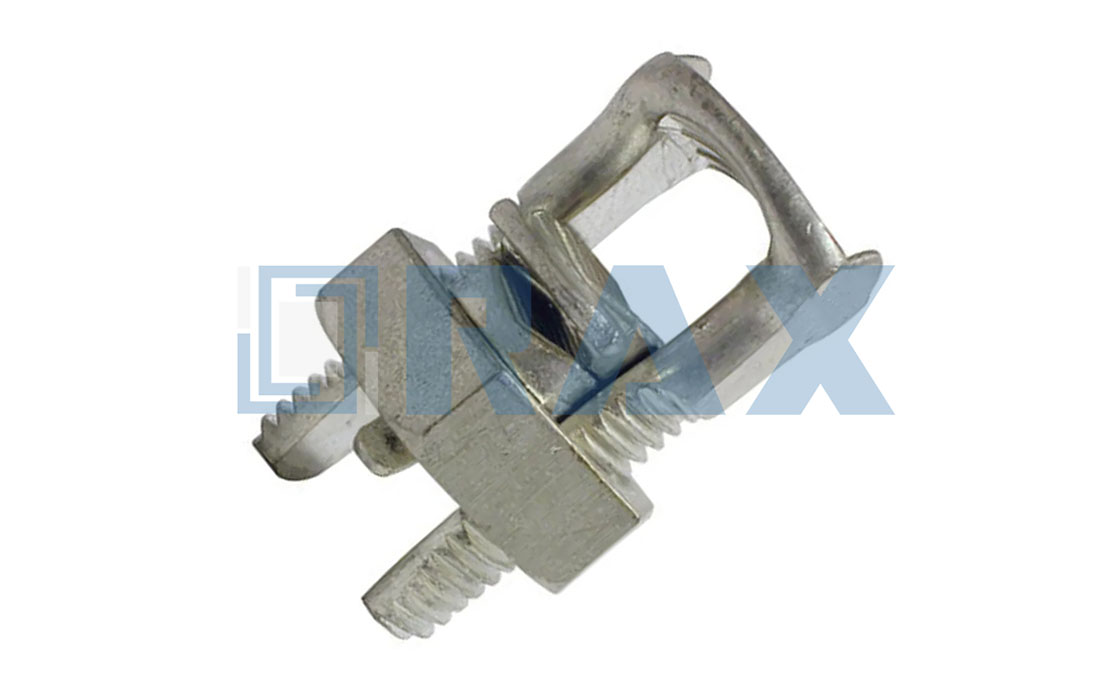

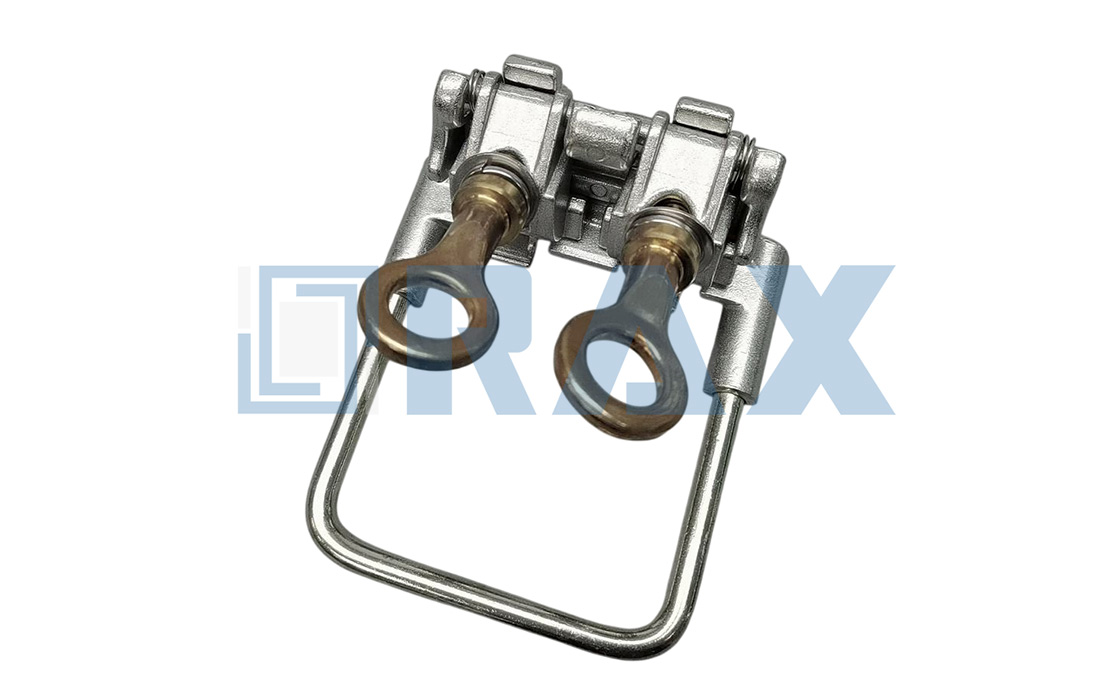

What tools are required for installing C-Tap connectors?

A special crimping tool is required for installation, often featuring color-coded dies that emboss codes on the connector for verification. These tools ensure proper compression and achieve secure, low-resistance connections, making installation straightforward with consistent results.

Can C-Tap connectors be used for direct burial applications?

Some C-Tap connector models are UL-approved for direct burial, making them suitable for underground or outdoor use where moisture and environmental factors are present. Always check specific product specifications for direct burial suitability.

Get A Quick Quotation Today