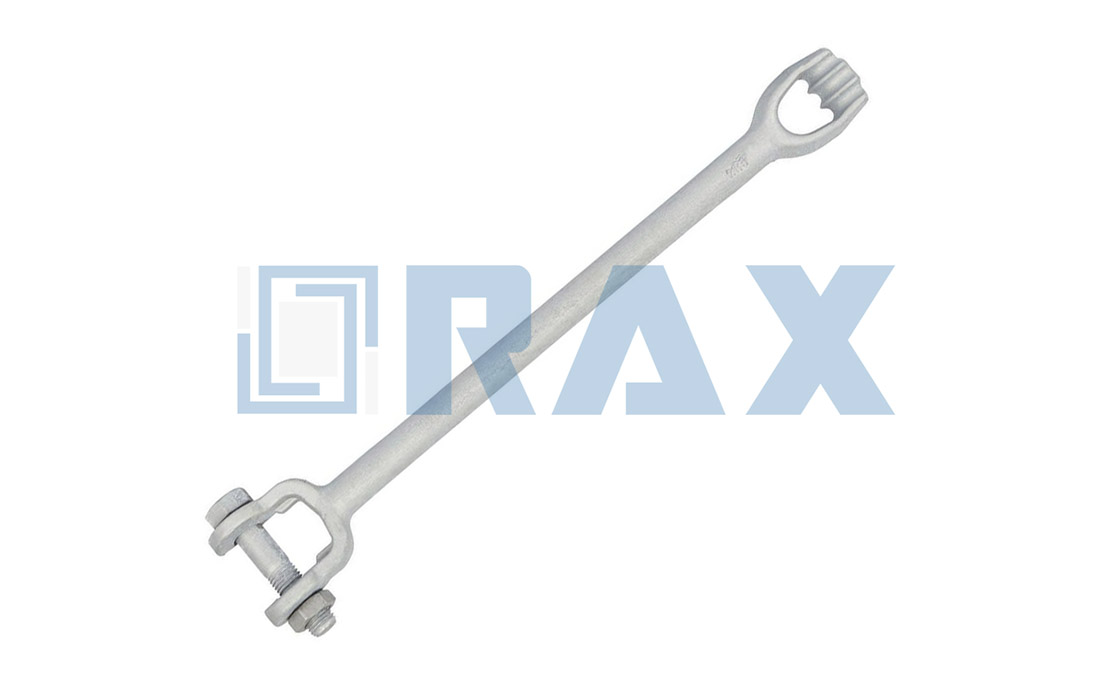

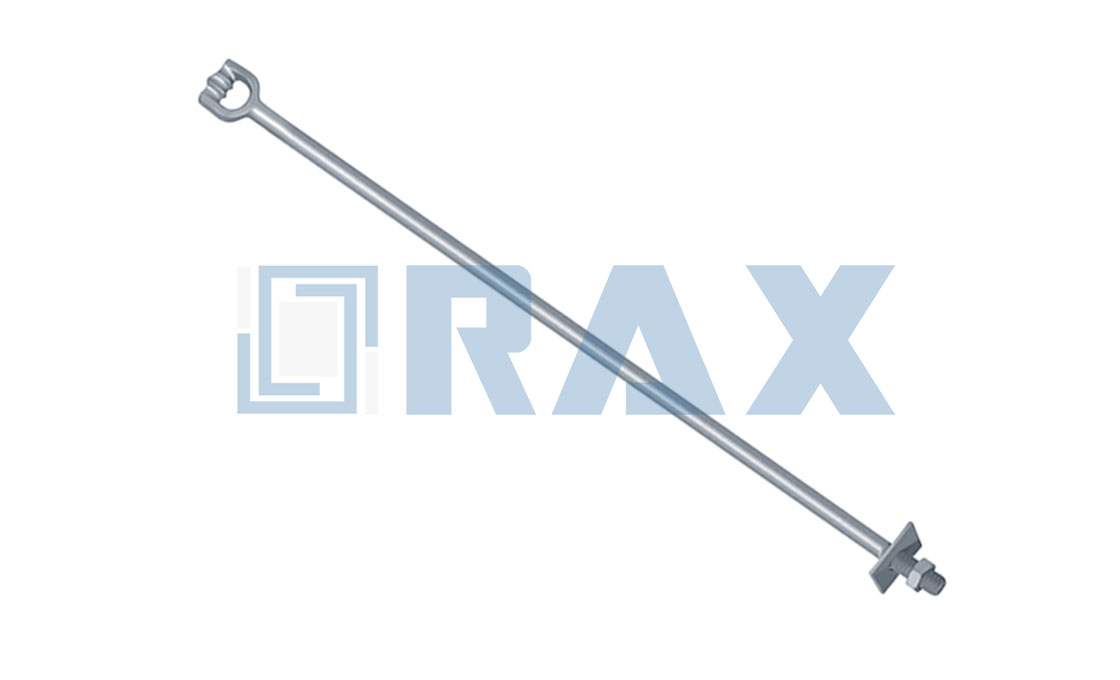

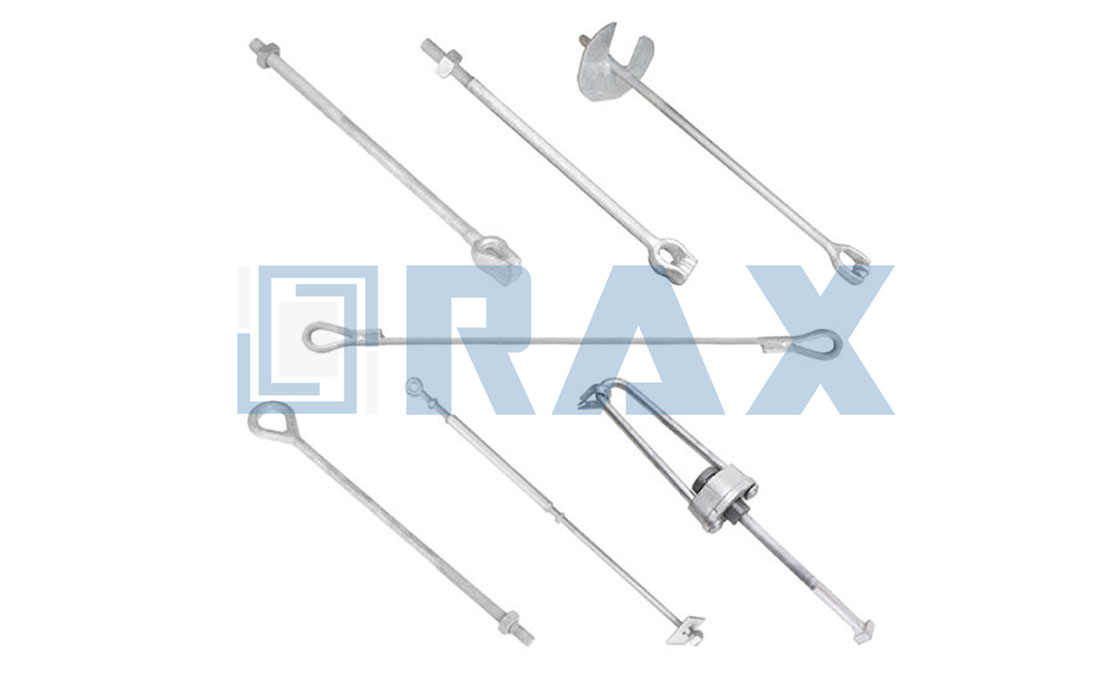

Helical anchor extensions are steel components that extend helical pile systems to achieve required installation depths. They connect to lead sections and are driven into the ground using torque motors, anchoring securely in load-bearing soil strata. By adding extensions sequentially, installers penetrate to stable soil layers, ensuring the anchor engages with competent strata for both tension and compression resistance.

Helical anchor extensions enable immediate load transfer upon installation with minimal soil disturbance. They support all-weather operation, require no concrete, and generate limited spoils. Key advantages include steady installation rates, capacity verification through torque application, and reliable performance across diverse site conditions and weak soil environments.

Material composition involves high-strength steel, typically 80 KSI grade, hot-dip galvanized per ASTM A123 specifications. Manufacturing incorporates patented inertia welding to join components without added metals, with flights plasma-cut from grade 50 plate and formed to precise pitches by certified D1.1 welders. Technical specifications include tensile strength up to 200,000 pounds, torque ratings from 7,000 to 21,000 foot-pounds, extension lengths from 3.5 to 10 feet, and helix diameters of 8, 10, 12, or 14 inches.

Helical anchor extensions are widely used in electric utility transmission, telecommunications, wind energy, and solar installations. Applications include guy wire anchoring, tower and pole support, shoring systems, and foundation support for monopoles and structures in remote or limited-access sites. Installation requires alignment within 5 degrees and proceeds at approximately 3 inches per rotation until target depth or torque is achieved.

Helical Anchor Extension: Engineered for Superior Strength and Performance

RaxPower is ‘The Very Best’ manufacturer of helical anchor extensions for:

- utility

- cell tower

- wind turbine industries

We manufacture the strongest extensions in the helical industry, designed and engineered to perform.

The helical anchor extension is essential for extending the steel to the required depth, allowing the lead section to anchor securely to the proper strata.

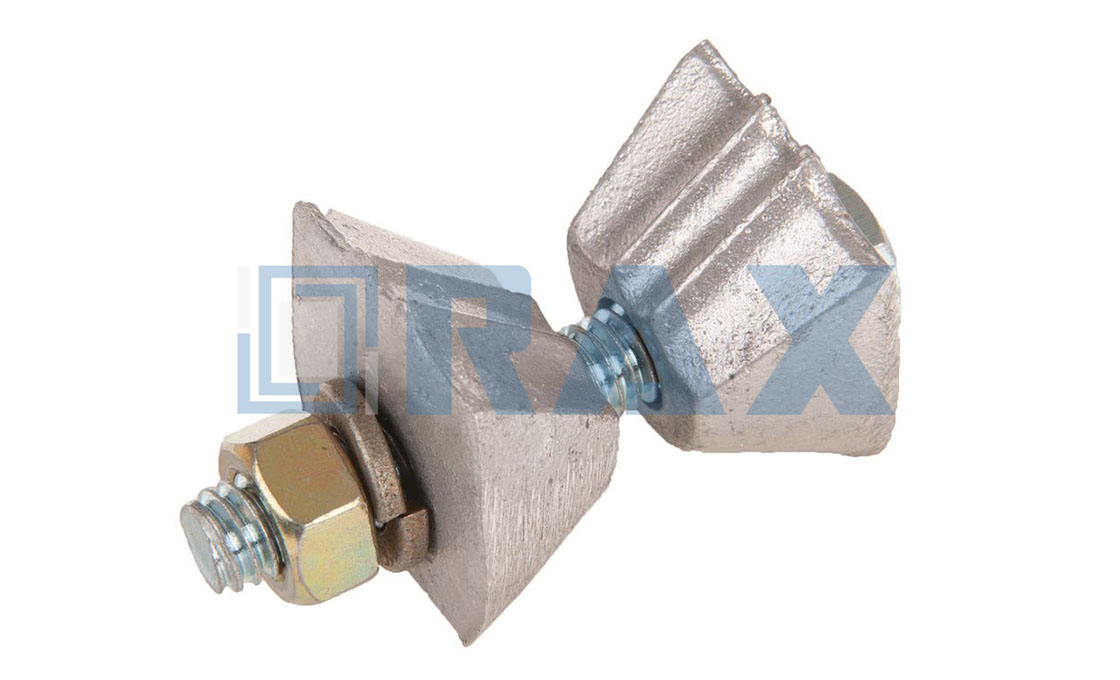

Our superior patented inertia welding technology ensures unmatched strength by rotating and pressing two pieces of steel together, generating friction and heat to forge them as one without added metals, human error, or special skill requirements.

With over 21 years of experience in manufacturing and exporting pole line hardware, our extensions are trusted for applications in:

- guy wires

- transmission towers

- wind turbine foundations

Our engineering team provides full support from conception to completion, leveraging advanced processes like hot forging and strict quality control.

Don’t wait, call the steel utility foundation experts today.

| Parameter | Value |

|---|---|

| Type | Anchor Extensions |

| Application | Helical Anchoring |

| Shaft Size | 1-1/2″ to 2-1/4″ Square Bar, 2-7/8″ Round Tubular |

| Length | 3.5 ft to 10 ft (42 in to 120 in) |

| Weight | 18 lb to 140 lb (8.2 kg to 63.5 kg) |

| Number of Helices | 0 to 3 |

| Helix Diameter(s) | 8 in, 10 in, 12 in, 14 in |

| Tensile Strength | Up to 200,000 lb |

| Torque Rating | 7,000 ft-lbs to 21,000 ft-lbs |

| Coating | Hot-Dip Galvanized per ASTM A123 |

| Material | High-Strength Steel (80 KSI to 107 KSI) |

| Certifications | ASTM A123, Buy America(n) Qualified |

| Strength Note | Ultimate strength ratings apply to properly installed anchors only. Failure to install within 5° of alignment may significantly lower strength. |

| Standard Package | 1 |

Frequently Asked Questions

What is a helical anchor extension used for?

Helical anchor extensions are used for helical anchoring in weak soil conditions or areas needing higher holding capacities, such as supporting power poles and other structures in power line transmission systems.

What are the specifications and dimensions?

The extension features a tensile strength of 70,000 lb, torque rating of 7,000 ft-lbs, length of 123 inches, 3 helices with 14-inch diameters, weight of 138.837 lb, and galvanized finish for corrosion protection.

Are there any special installation requirements?

Ultimate strength ratings apply to properly installed anchors only. Installation must be within 5° of alignment with the guy load, as exceeding this may significantly lower strength. Bolts and nuts are pre-assembled at the factory.

How do you ensure reliability and compliance for critical infrastructure applications?

RaxPower employs strict quality control with multi-stage testing and review processes. All products undergo load testing and gauge tests per IEC 120 standards. Hot-dip galvanizing per ISO 1461 ensures corrosion resistance, while automated manufacturing guarantees precise sizing. Products are certified by SGS and authoritative research institutes.

What engineering support do you provide for project-specific requirements?

Our team of professional engineers and technicians assists in analyzing load requirements and soil data to recommend optimal configurations. We provide tailored solutions, including custom designs if needed, to ensure proper performance and compliance with project specifications.

Can you handle large-scale orders with guaranteed on-time delivery?

Yes. With 17,000 square meters of production space and 5,000 square meters of warehouses, we maintain substantial inventory of standard items. Our automated processes ensure consistent production flow, enabling reliable on-time delivery for demanding large-scale installations.

How does your manufacturing process achieve cost savings for OEM clients?

Advanced hot forging technology and automated machinery produce high-strength extensions with accurate dimensions. This efficient approach reduces waste and labor costs, enabling competitive pricing. Strict quality control, including raw material selection and twice-reviewed packing, ensures consistent quality while delivering significant cost savings compared to in-house production.

Get A Quick Quotation Today