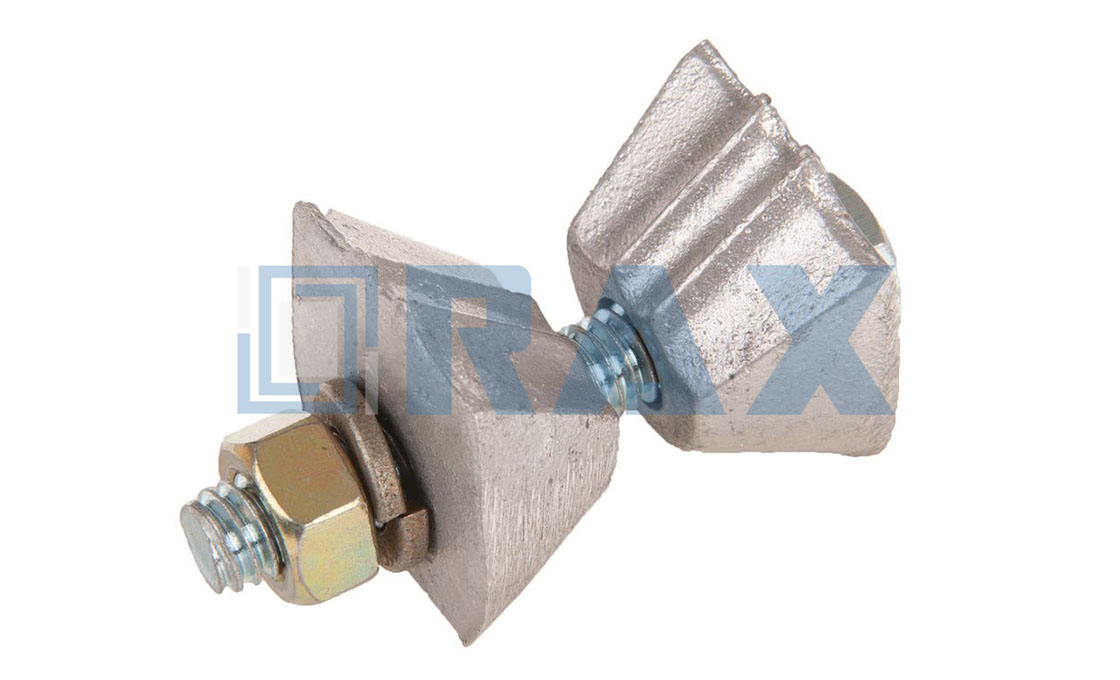

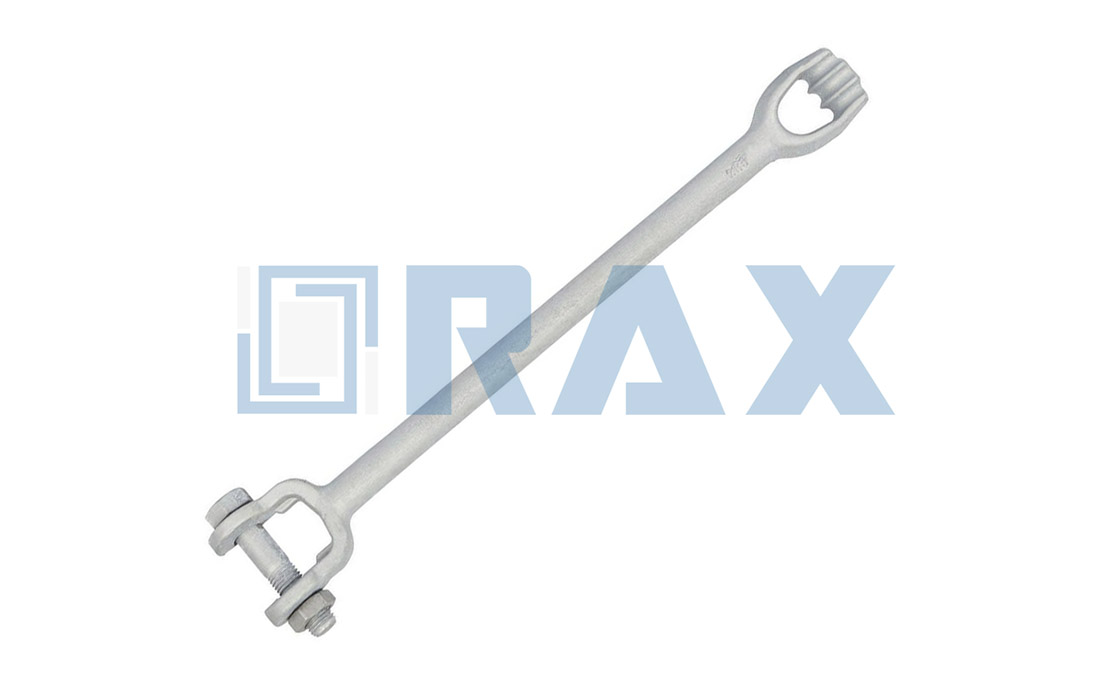

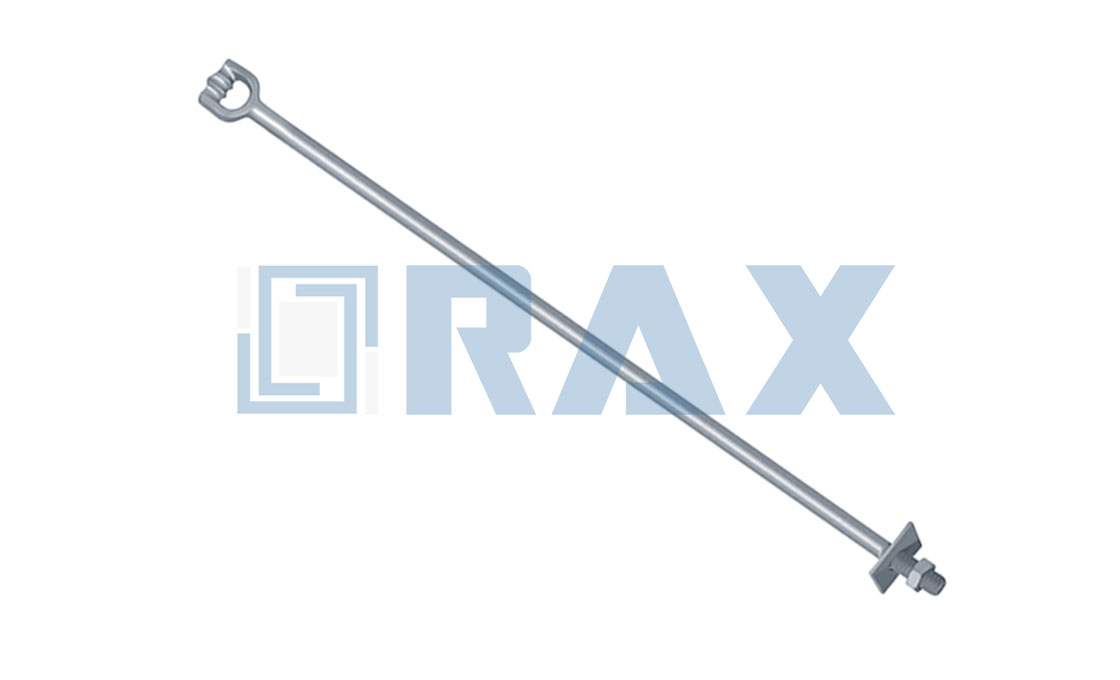

An anchor rod coupler joins two anchor rods together, enabling deeper installation depths or extending the eyenut above grade. It creates a secure mechanical connection for rod length extension or coupling rods with different diameters, facilitating customization to meet specific project requirements. This method eliminates welding, making it suitable for delicate structures where welding could cause damage.

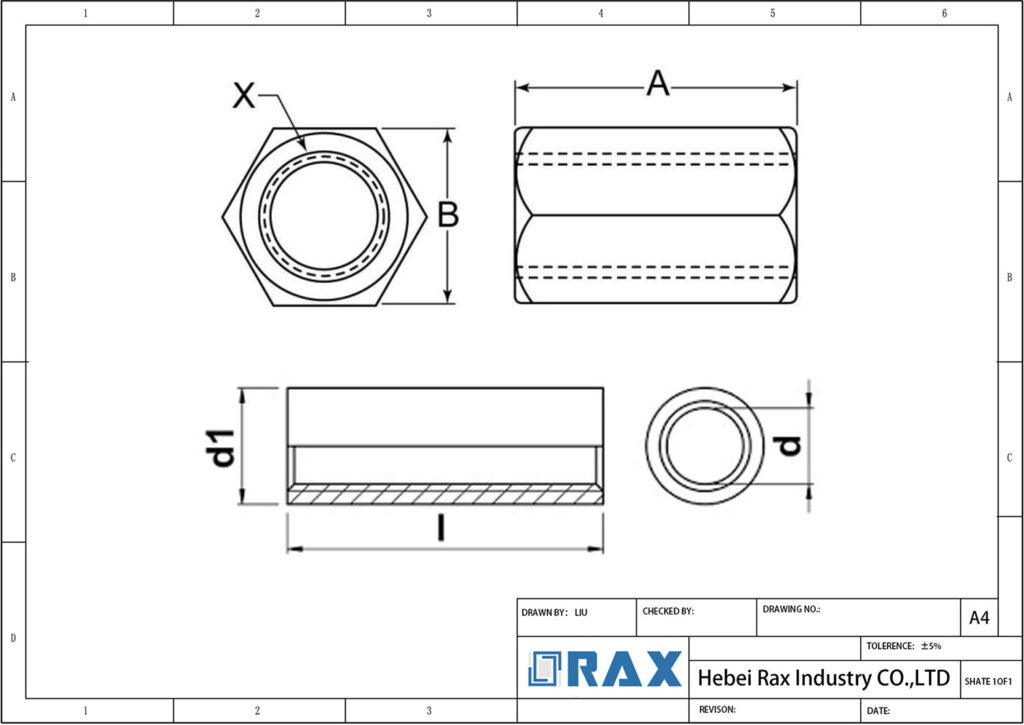

The coupler body uses seamless tubing made of high-strength alloys such as galvanized steel or carbon steel. Internal threads are precision-tapped from each end to accommodate rod insertion and secure fastening, with some designs incorporating a center stop for optimal alignment. Materials like carbon steel comply with ASTM A563 standards, and finishes such as electrogalvanized or hot-dip galvanized per ASTM A153 provide resistance to moisture and corrosion.

Anchor rod couplers are available in diameters from 1/4 inch to 1 inch and lengths such as 1-1/2 inches or 4-1/2 inches. Installation requires only standard tools like a wrench for tightening, enhancing efficiency on site. The couplers develop the full load capacity of the rods, with some models offering safe working loads up to 38,000 pounds and a safety factor of 2:1, supported by durable finishes that improve abrasion resistance and long-term performance in structural and mechanical assemblies.

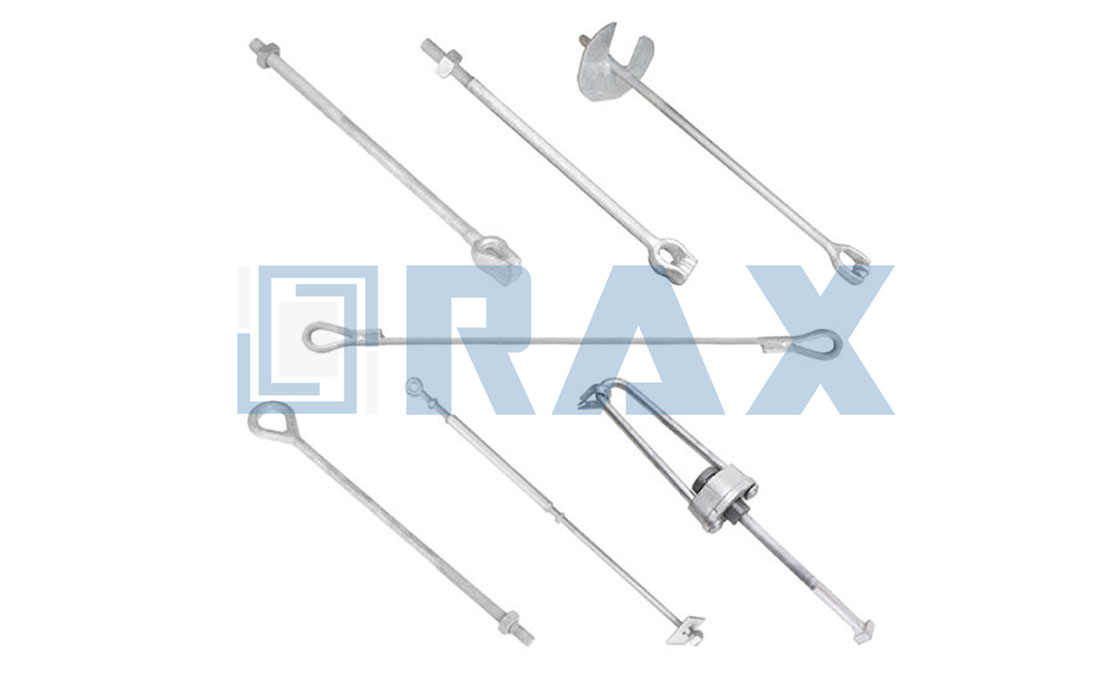

Anchor Rod Coupler Supplier for Strong and Reliable Connections

RaxPower is your trusted manufacturer of anchor rod couplers from China. We offer a comprehensive range of precision-engineered couplers, designed for strong and reliable connections in various applications. Our anchor rod couplers are available in diverse sizes and durable materials like carbon steel and stainless steel, ensuring exceptional stability and longevity. Partner with us for dependable, cost-effective fastening solutions directly from the source.

With over 21 years of manufacturing expertise based in Hebei Province, RaxPower leverages advanced processes like hot forging and automated machining to produce anchor rod couplers with greater strength and accurate sizing. Our commitment to superior material quality and strict quality control—including multi-stage testing and galvanization per international standards—ensures each coupler delivers secure, wobble-free connections that withstand demanding environments. These couplers are ideal for extending or joining threaded rods in construction, anchoring systems, and industrial projects, providing versatile and long-lasting performance. Trust us for high-quality, cost-effective fastening solutions directly from a leading manufacturer.

| Parameter | Value |

|---|---|

| Material | Carbon Steel, Stainless Steel |

| Material Standard | ASTM A563 |

| Finish | Electrogalvanized or Hot-Dip Galvanized |

| Finish Standard | ASTM A153 |

| Type | Round |

| Thread Diameter Range | 1/4″ to 1″ |

| Length | 1-1/2″ to 4-1/2″ |

| Safe Working Load | 38,000 lbs |

| Safety Factor | 2:1 |

| Tensile Strength | 36,000 lbs |

| Center Stop | Yes |

| Environmental Conditions | Dry indoor settings, areas with temporary condensation |

Frequently Asked Questions

What is an anchor rod coupler and what is its purpose?

An anchor rod coupler binds two anchor rods together to achieve greater installation depths or extend the eyenut above grade. It combines shorter rod lengths to create longer anchor rods, customizing length and mechanical strength to support structures and improve load bearing capacity.

What are the advantages of using anchor rod couplers?

Anchor rod couplers allow customization of rod lengths for specific project needs, improve mechanical strength and load bearing capacity, provide secure connections without welding (ideal for delicate structures), and enhance overall project efficiency and stability.

How does an anchor rod coupler connect two rods?

The coupler features a body made of seamless tubing with internal threads. Rods of different diameters are inserted and secured into the tubing on both ends, creating a secure mechanical connection without welding.

What materials are used in anchor rod couplers?

Anchor rod couplers are made from high-strength durable alloys like galvanized steel, using seamless tubing for the body to ensure durability and a secure connection that maintains structural integrity in demanding environments.

How is an anchor rod coupler installed?

Installation is simple and requires no welding. The coupler is tightened with a standard wrench to secure the rods on both ends. No specialized equipment is needed, reducing installation time and complexity.

How does the no-welding design enhance safety and cost-efficiency?

The no-welding design eliminates risks associated with welding on delicate structures that may not withstand heat or stress. This reduces potential costs from specialized equipment or damage, making it ideal for sensitive job sites in railways, utilities, and manufacturing.

What sizes and specifications are available?

RaxPower anchor rod couplers are available in various sizes such as M2, M2.5, M3, M4, M5, and M6, with different lengths and thread diameters to suit different rod sizes and accommodate project-specific requirements for bulk supply in sectors like EPC contracting and renewable energy.

Get A Quick Quotation Today