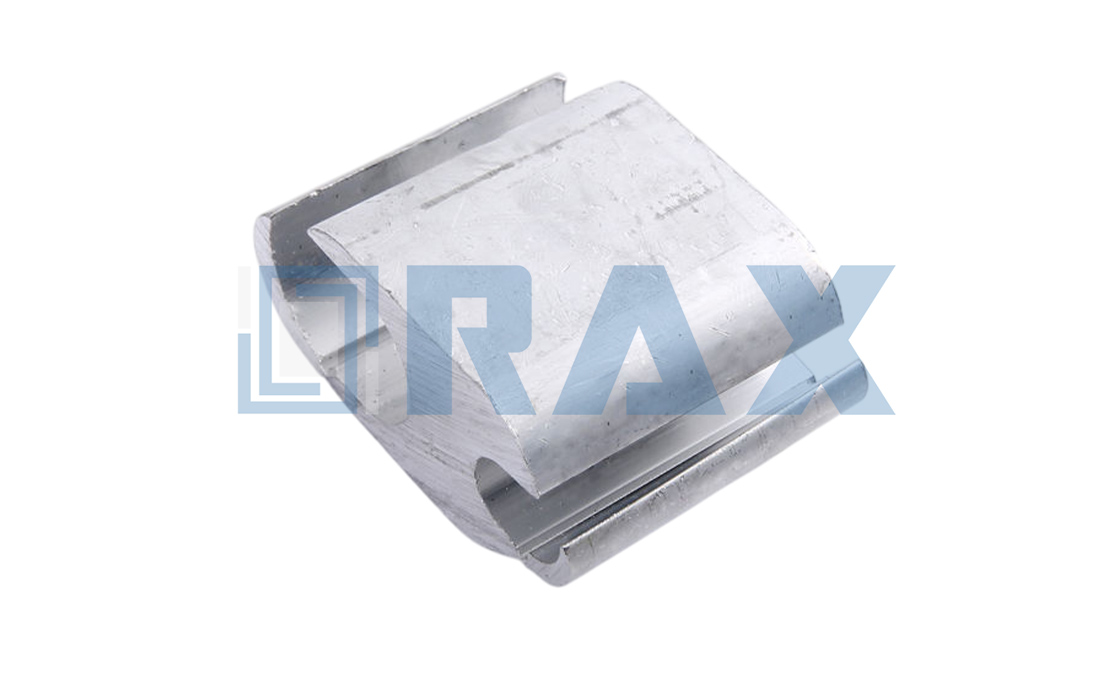

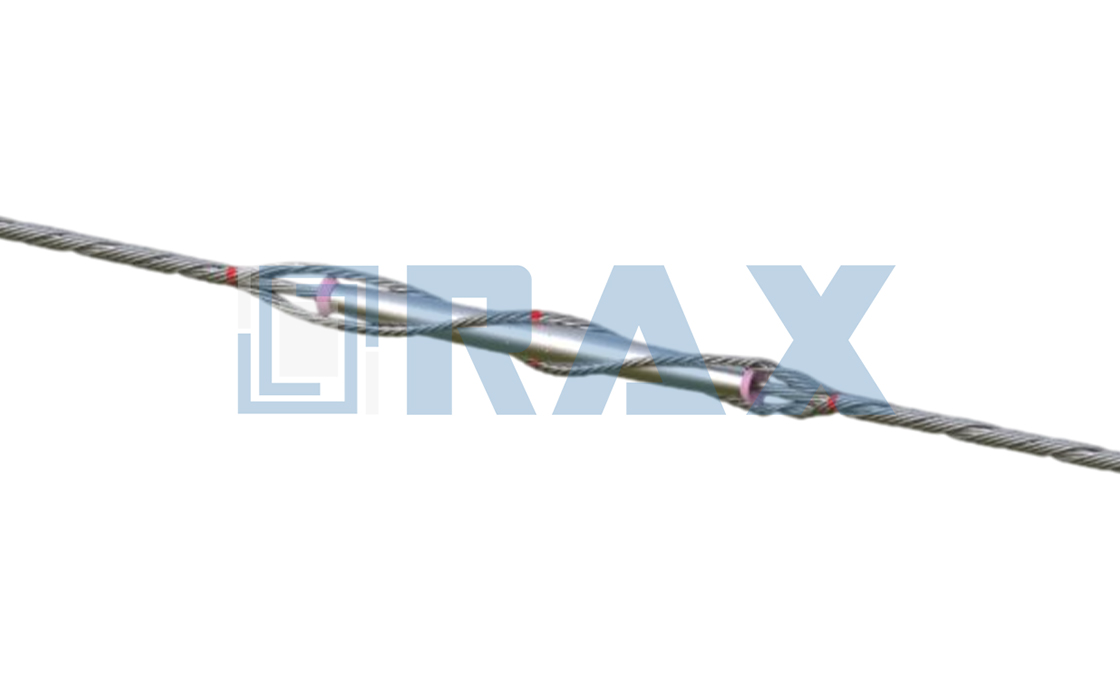

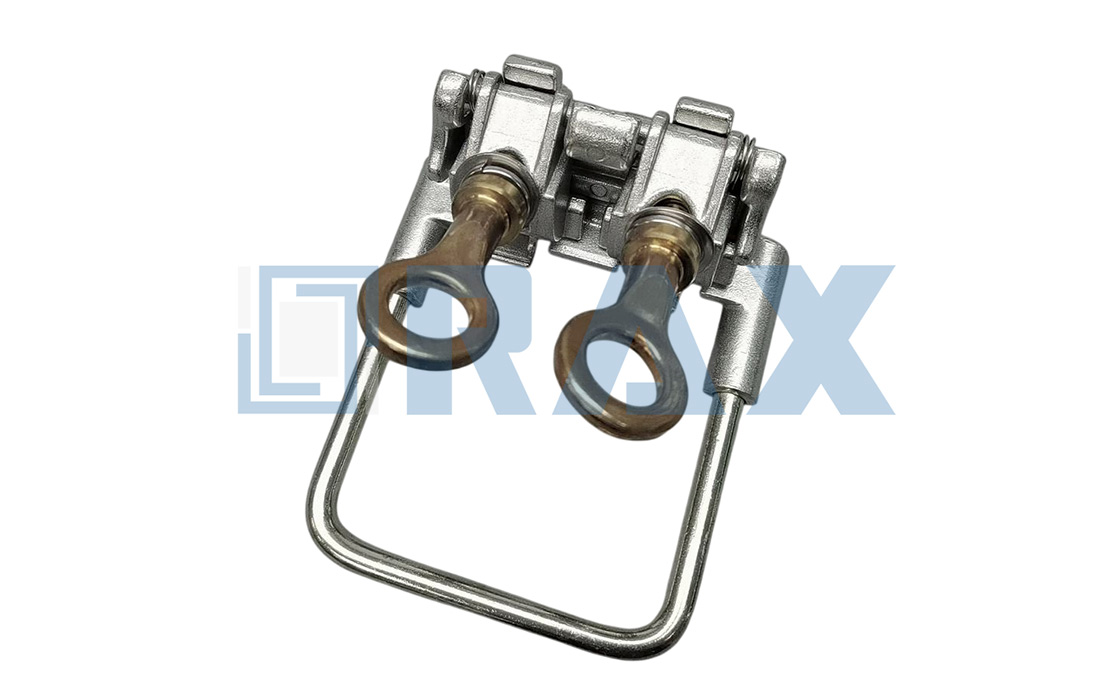

The H-Tap Compression Connector creates secondary taps on main conductors in overhead and distribution systems, supporting aluminum-to-aluminum and aluminum-to-copper combinations for secondary splice or tap applications. Constructed from 1350 aluminum alloy, the connector provides high strength and conductivity while its tin plating and pre-filled oxide inhibitor offer corrosion resistance.

The field-proven ribbed design ensures reliable contact with conductors without distorting their shape. Fold-in tabs create a positive interlock as the compression tool closes, enhancing connection security and stability during installation. This design enables lower connection costs and simplified installation procedures, reducing labor and time requirements.

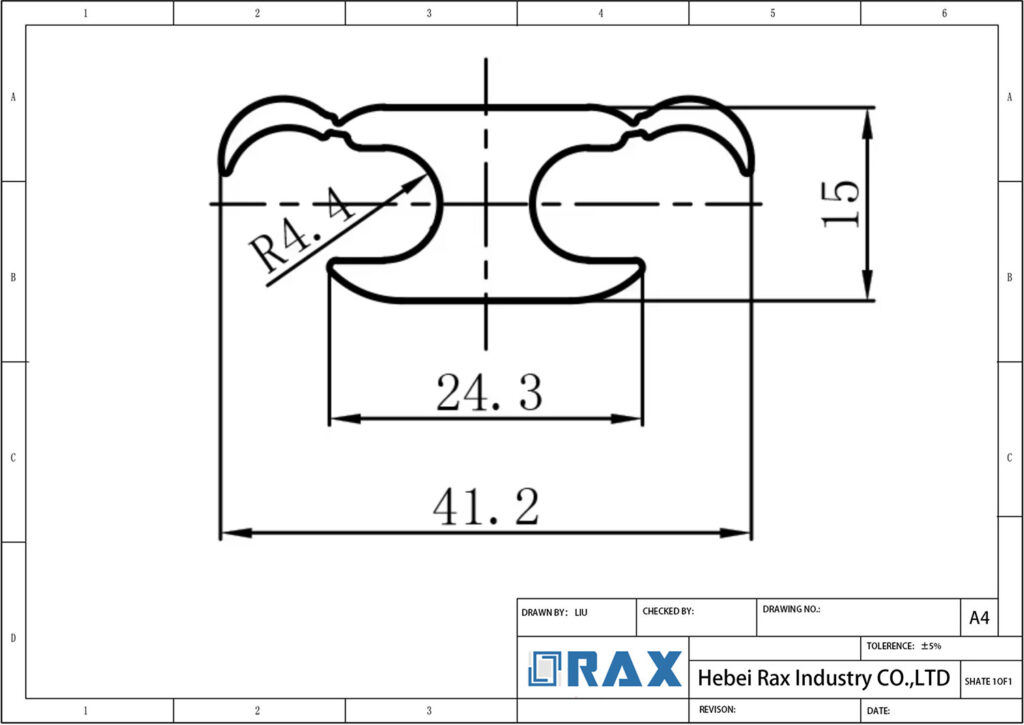

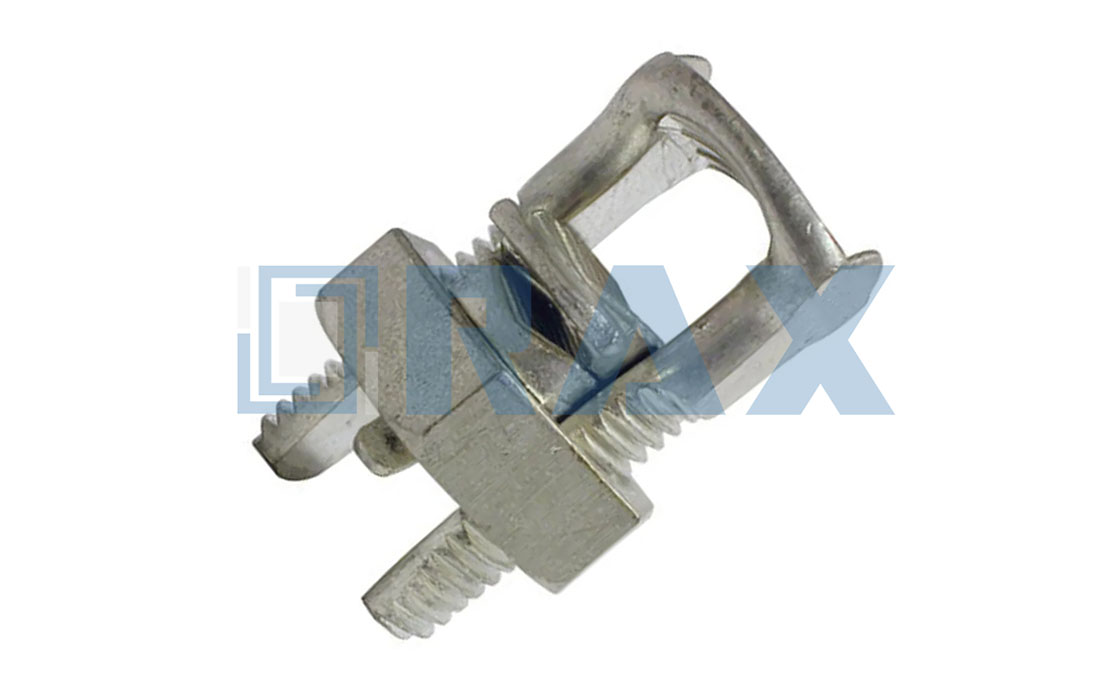

Installation uses standard compression tools with O and D dies, requiring no special equipment. The connector accommodates conductor sizes from 2 American Wire Gauge (AWG) to 500 kcmil for run conductors, with similar ranges for tap conductors. It supports both solid and stranded conductors with a 600 V voltage rating and operating temperatures up to 90°C.

The H-Tap Compression Connector complies with ANSI C119.4 standards and is RUS Accepted, meeting rigorous performance and safety requirements for regulated electrical systems.

H-Tap Compression Connector Wholesaler with ANSI Compliance

RaxPower is a complete and reliable manufacturer of pole line hardware, established in 2003 in Hebei Province, China, with 21 years of expertise in serving global construction needs. Our H-Tap Compression Connector embodies this commitment, designed for superior performance and manufactured using high-strength aluminum alloy through advanced hot forging technology for enhanced durability and precise sizing.

Key Features

- Prefilled with oxide inhibitor to ensure corrosion resistance.

- Installed with industry standard “O” and “D” dies for convenient and secure compression.

- Field-proven ribbed design provides excellent connector/conductor contact without distorting the conductor.

- Complies with ANSI C119.4 standards for reliable, credible performance.

Benefits

Delivers superior connector performance, lower connection costs, and simplified installation procedures. Positive mating with cable strands when compressed reduces installation time and effort.

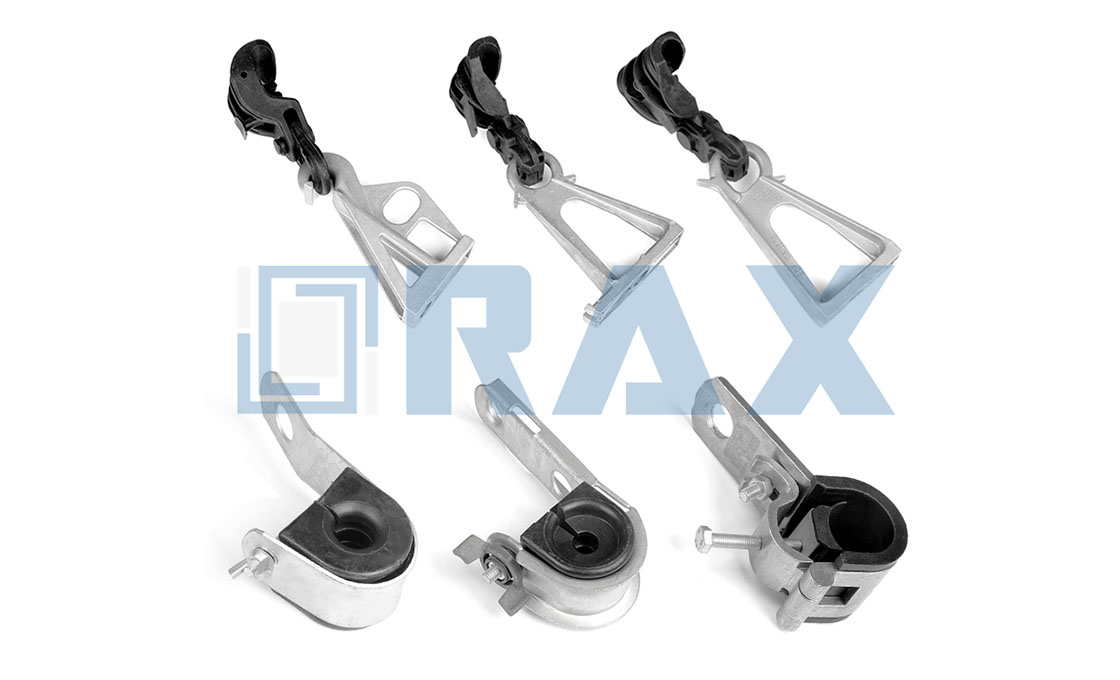

Applications

Ideal for secondary splice or tap applications, accommodating combinations of aluminum to aluminum and aluminum to copper conductors.

Leveraging our 17,000 sqm production workshops and strict quality control—including raw material selection, multi-stage testing, and automation—we ensure 100% product reliability and on-time delivery. Our team of over 170 professionals, including engineers and technicians, supports consistent quality across all outputs.

Contact us for inquiries at sales@kjcontrols.com.

| Parameter | Specification |

|---|---|

| Product Type | H-Tap Compression Connector |

| Run Conductor Size | 2 AWG to 500 kcmil |

| Tap Conductor Size | 2 AWG to 500 kcmil |

| Material | 1350 Aluminum Alloy |

| Number of Taps | 2 |

| Finish | Tin Plated |

| Overall Length | 1-1/2 inches to 2-7/16 inches |

| Operating Temperature | 90°C |

| Voltage Rating | 600 V |

| Recommended Die Index | O and D dies |

| For Use With | Combinations of aluminum to aluminum and aluminum to copper conductors |

| Standards | ANSI C119.4, RUS Accepted |

| Application | Secondary splice or tap applications in electrical circuits |

Frequently Asked Questions (FAQS)

What are H-Tap Compression Connectors used for?

RaxPower H-Tap Compression Connectors are designed for combinations of aluminum to aluminum and aluminum to copper conductors, making them versatile for various electrical connections such as secondary splices or tap applications.

What types of conductors and sizes are compatible with H-Tap Compression Connectors?

These connectors support a wide range of conductor sizes, including ACSR, stranded, and solid conductors. Run conductor sizes range from 2/0 to 1/0 AWG ACSR or 3/0 to 2/0 AWG stranded, while tap conductor sizes range from 2 to 6 AWG ACSR or 1/0 to 6 AWG solid or stranded.

How do your H-Tap connectors ensure long-term reliability and compliance?

Our connectors feature a field-proven ribbed design for excellent connector/conductor contact without distorting the conductor's shape, and are pre-filled with an oxide inhibitor held captive in the rib/connection area to prevent corrosion. They comply with rigorous standards including ANSI C119.4 and are RUS Accepted. RaxPower enhances this through multi-stage quality control, load testing, and SGS verification to guarantee 100% reliability and utility-grade performance.

Are your connectors suitable for harsh environments like railway or renewable energy systems?

Absolutely. Made from high-strength 1350 aluminum alloy with corrosion-resistant designs, our connectors withstand constant vibration and extreme conditions. They comply with industry-specific standards and undergo thorough load and gauge testing at RaxPower, ensuring durability for specialized applications like railway electrification and renewable energy grid connections.

How are H-Tap Compression Connectors installed?

Installation is straightforward using standard compression tools and dies, such as O and D dies. The fold-in tabs provide positive tab interlock as the tool closes, simplifying the process without requiring special tools or incurring additional costs.

What are the temperature and voltage ratings for H-Tap Compression Connectors?

RaxPower H-Tap Compression Connectors have a temperature rating of 90°C and a voltage rating of 600V, making them suitable for a variety of electrical applications under different conditions.

Can you support large-scale projects with consistent bulk supply and on-time delivery?

Yes, we offer flexible packaging options from units to pallets. Our automated production processes and 5,000 square meters of warehouse space enable efficient handling of bulk orders. RaxPower's extensive experience and streamlined logistics ensure timely delivery to meet the demands of EPC contractors and major projects without delays.

How do you maintain competitive pricing while offering a wide range of connector sizes and types?

By leveraging advanced manufacturing techniques like hot forging and maintaining high production volumes, we achieve cost efficiencies without sacrificing quality. RaxPower provides a comprehensive catalog covering various run and tap conductor sizes, supported by semi-automatic molds and strict raw material selection, ensuring distributors and OEMs receive low wholesale prices and consistent product variety.

Get A Quick Quotation Today