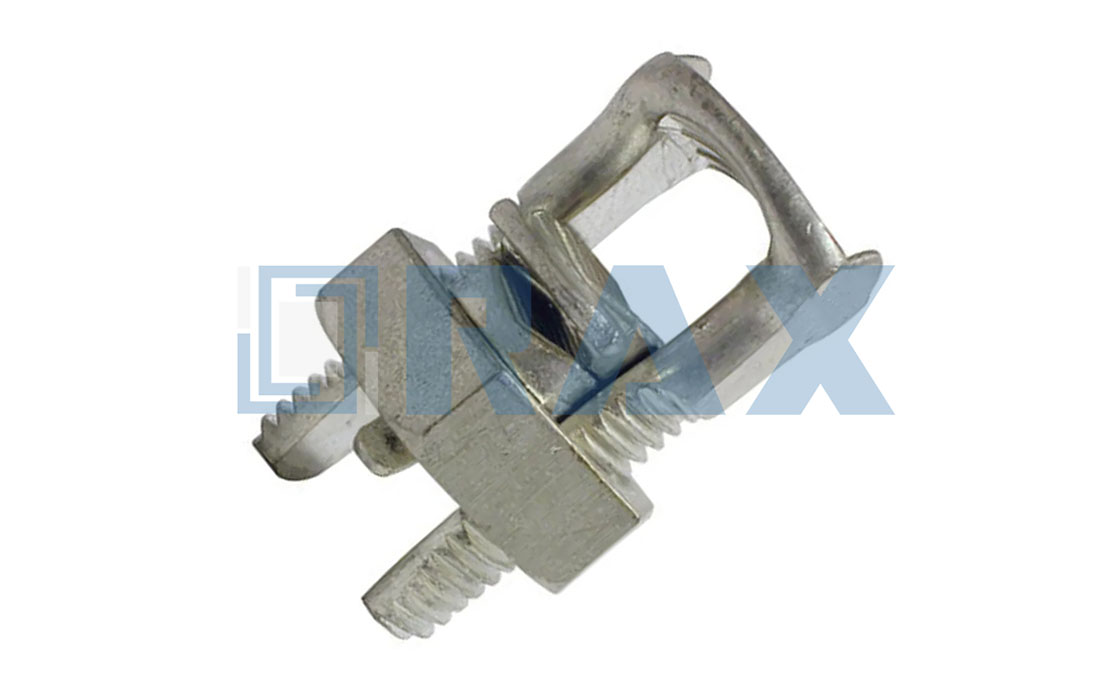

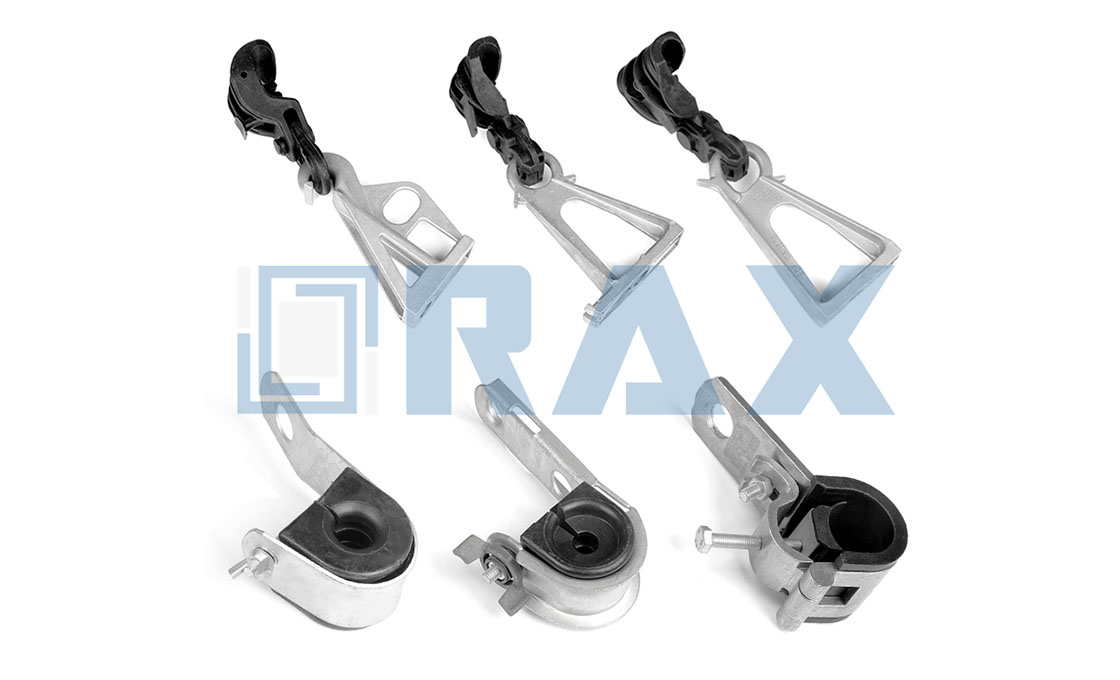

An insulation piercing connector creates electrical connections by piercing conductor insulation without stripping, functioning as a splice or tap for various conductor types in low voltage systems. The connector eliminates stripping, reducing installation time and minimizing conductor damage. Self-insulated construction allows hot line use without additional taping, helping prevent power interruptions.

The body is molded from glass-filled nylon or resilient polymers for breakage resistance and long-term use. Piercing teeth are made of hardened copper, tin-plated copper, or aluminum alloys for enhanced corrosion resistance and durability. Design features include compact form factor, visual guides for conductor placement, and breakaway torque nuts that snap off when Underwriters Laboratories (UL) torque requirements are met. Grease-filled rubber end caps provide water and corrosion resistance.

These connectors serve low voltage power distribution systems, including overhead bundled cables, street lighting, and branch connections. They accommodate copper-to-copper, copper-to-aluminum, and aluminum-to-aluminum connections in insulated environments, rated for voltages up to 600 volts and temperatures up to 90 degrees Celsius.

Installation uses standard socket wrenches, with tightening until the torque nut breaks away indicating correct installation. Connectors accommodate main conductors from 4/0 American Wire Gauge (AWG) to 4 AWG and tap conductors from 6 AWG to 14 AWG, depending on model. Products comply with UL 486A/B and Canadian Standards Association (CSA) standards.

Insulation Piercing Connector Manufacturer

RaxPower is your reliable manufacturer and supplier in China with over 21 years of experience in pole line hardware, specializing in the R&D and production of electrical accessories. Our Insulation Piercing Connectors are engineered to deliver a reliable and efficient solution for connecting and piercing insulation in power distribution systems.

With a commitment to quality and innovation, we utilize high-quality materials and advanced processes like hot forging to ensure superior strength and accuracy in every connector. Each product undergoes rigorous testing, including load and gauge tests, and is certified to meet international standards such as VDE, NFC, ESI, BS, and CENELEC EN 50483-4, having passed SGS and authoritative institute verifications.

These connectors feature waterproof design, easy installation, and resilience in harsh environments, providing secure connections that minimize insulation damage.

Backed by our extensive expertise and strict quality control, we have exported to over 200 global clients, building trust through consistent performance in various power projects. Contact us today to learn more about our products and how we can meet your requirements.

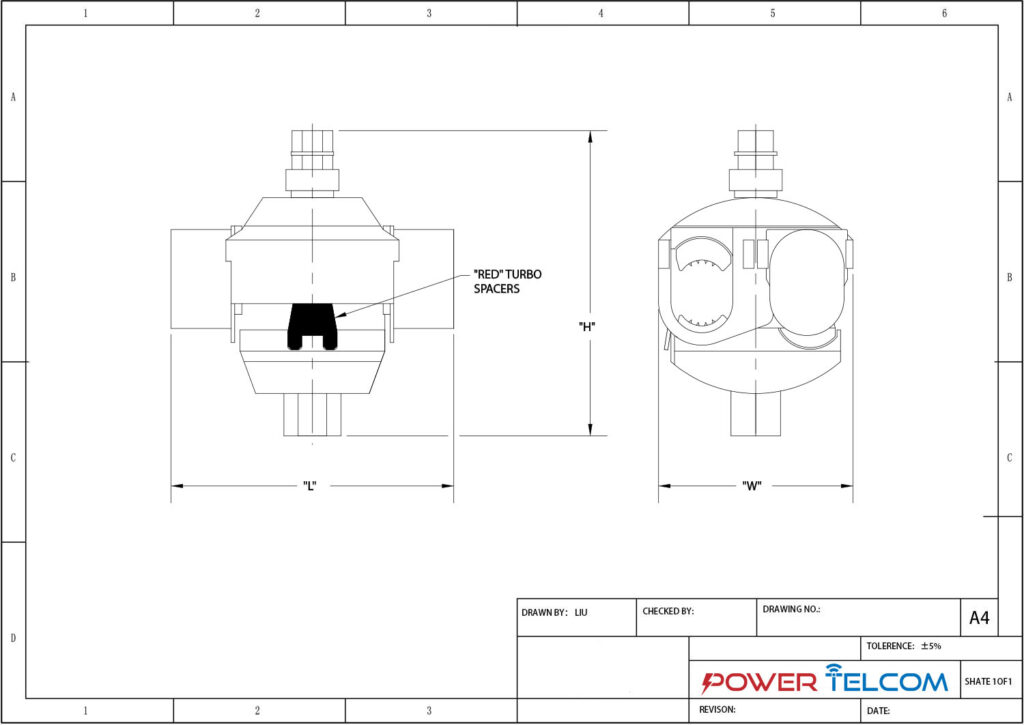

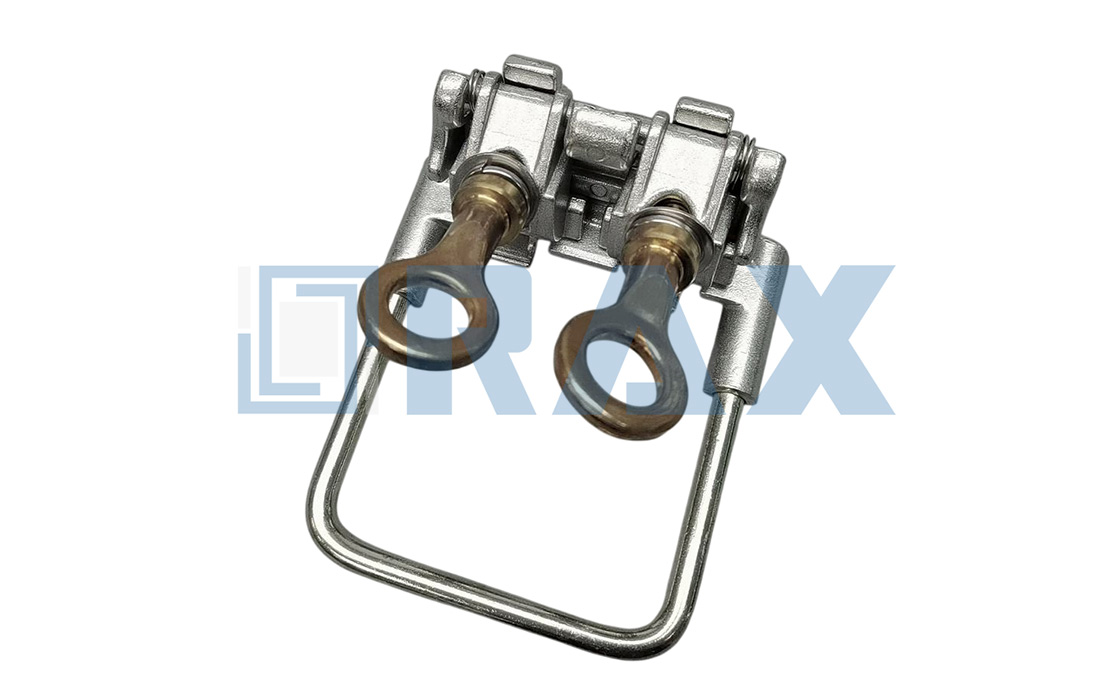

| Parameter | Value |

|---|---|

| Type | Dual-Rated |

| Number of Ports | 1 |

| Conductor Size (Main) | 4/0 AWG to 4 AWG |

| Conductor Size (Tap) | 6 AWG to 14 AWG |

| Number of Conductors | 2 |

| Color | Black |

| Conductor Compatibility | Copper-to-Copper, Copper-to-Aluminum, Aluminum-to-Aluminum |

| Voltage Rating | 600 V |

| Current Rating | 150 A Aluminum, 195 A Copper |

| Temperature Rating | 90 °C |

| Material (Body) | Glass-Filled Nylon or Resilient Polymers |

| Material (Teeth) | Hardened Copper, Tin-Plated Copper, or Aluminum Alloys |

| Dimensions | 1.453 in W x 1.928 in H |

| Tightening Torque | 80 in/lb |

| Weather Resistance | Yes, with grease-filled rubber end caps |

| For Use With | Class B or C Stranded Conductor |

| Standards | UL 486A/B, CSA |

| Application | Insulation Piercing Connector for Low Voltage Power Distribution |

Frequently Asked Questions (FAQS)

What is an insulation piercing connector?

An insulation piercing connector is a device that pierces the insulation of cables to make electrical connections without stripping the insulation. It features a body molded from glass-filled nylon, with insulation-piercing teeth pre-filled with silicone lubricant. It can function as a splice or tap connector and provides a visual guide for proper installation.

What are the advantages of using insulation piercing connectors?

Key advantages include easy installation without insulation stripping, waterproof and weather-resistant design, reliable connections on energized systems, corrosion resistance, cost-effectiveness, and reduced downtime. They are suitable for copper-to-copper, copper-to-aluminum, and aluminum-to-aluminum connections in non-tension, insulated applications.

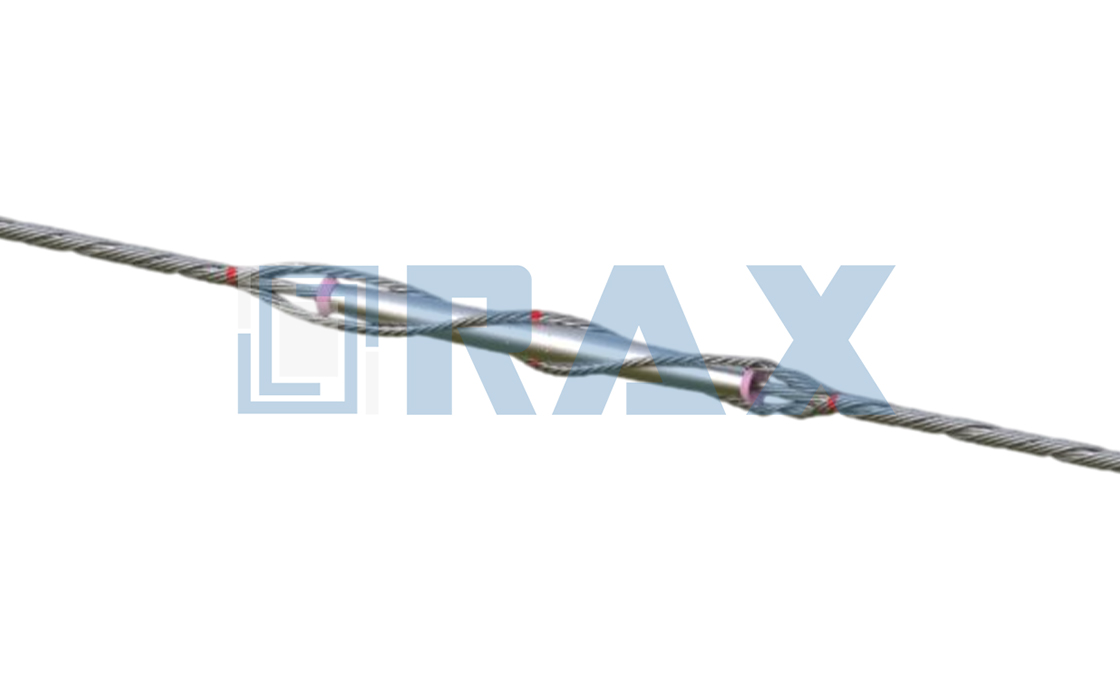

How do you install an insulation piercing connector?

Place the main and branch conductors into the connector, then use a socket wrench to tighten the torque nut until it breaks off at the specified torque value. This ensures a proper connection without damaging the conductors, and no additional taping is required.

What conductor size ranges and ratings are compatible with insulation piercing connectors?

Connectors support various conductor sizes, such as 4/0-4 AWG for the main conductor and 6-14 AWG for the tap, or ranges like 350-500 kcmil for the main and 4/0-4 AWG for the tap. They are dual-rated for copper and aluminum, rated for 600 volts, and can withstand temperatures up to 90°C in non-tension applications.

How can I be sure that your connectors meet the rigorous standards required for grid reliability?

Our insulation piercing connectors are certified to key industry standards such as UL 486A/B, CSA, and EN 50483-4, ensuring compliance and reliability for utility grid applications. They are built with high-quality materials like glass-filled nylon and tin-plated copper teeth for long-term dependability.

Do you support large-scale projects with reliable bulk supply and on-time delivery?

We accommodate bulk orders for major projects with efficient production processes to ensure on-time delivery, supported by our capability to handle high-volume demands and maintain quick production turnaround for global clients.

Can you provide cost-effective OEM solutions without compromising on quality consistency?

We offer OEM and ODM services with competitive pricing, utilizing high-quality raw materials and strict quality control measures to deliver consistent product quality and significant cost savings for your manufacturing needs.

What advantages do you offer to distributors in terms of pricing and product range?

We provide a broad catalog of insulation piercing connectors in various sizes and specifications, with competitive wholesale pricing to maximize your profit margins and meet diverse market demands.

Get A Quick Quotation Today