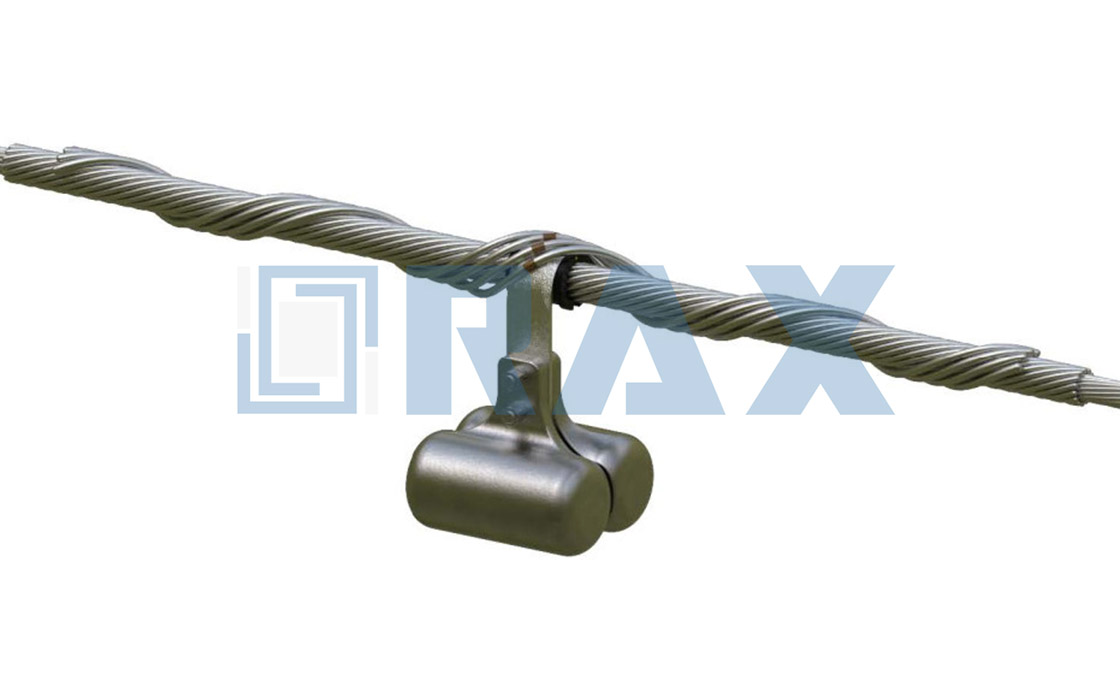

The Detuning Pendulum minimizes vertical conductor motion during galloping events on power transmission lines. Using a weighted arm that opposes rotational force on the conductor, the device alters its torsional frequency to prevent synchronization with vertical frequency, reducing both the number and amplitude of galloping events and minimizing line damage.

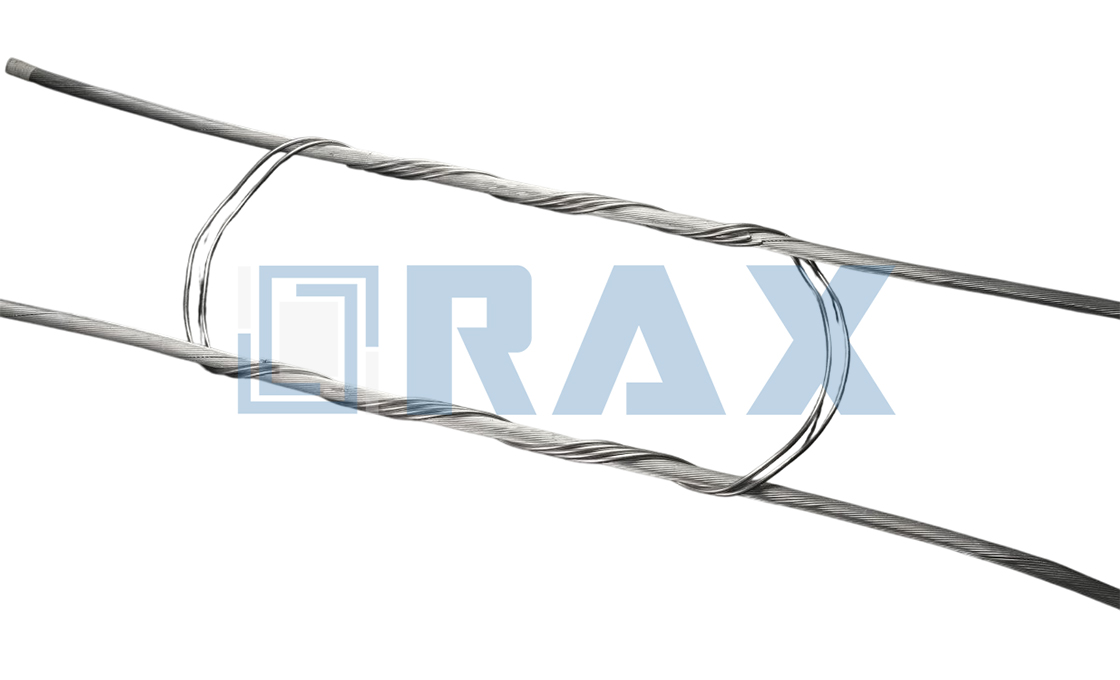

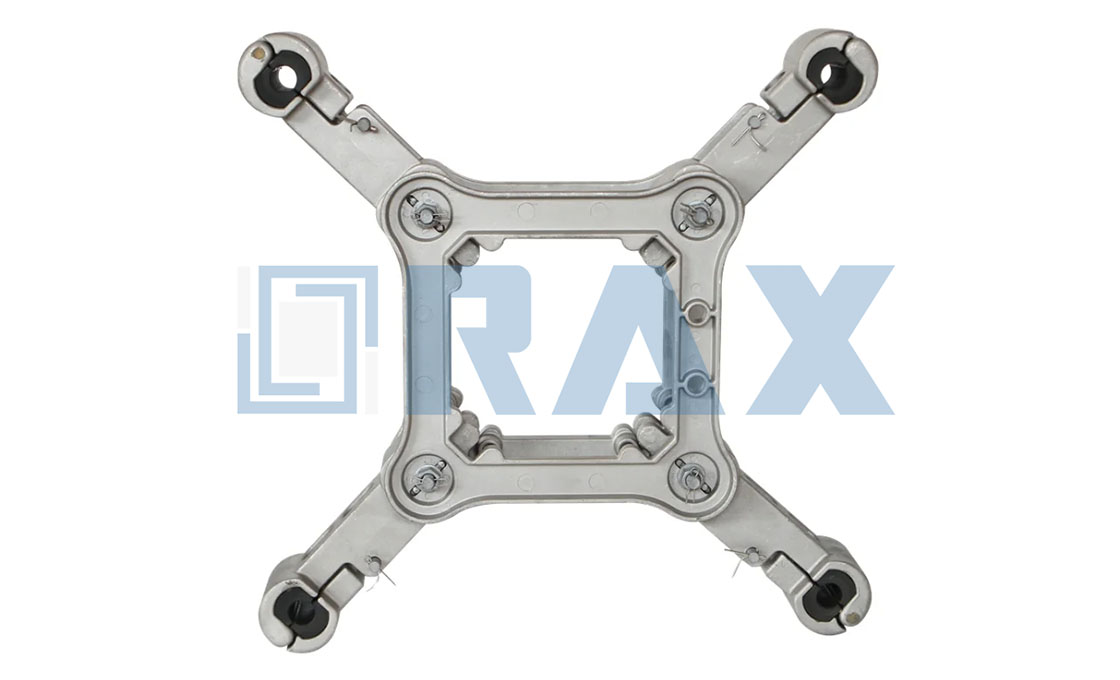

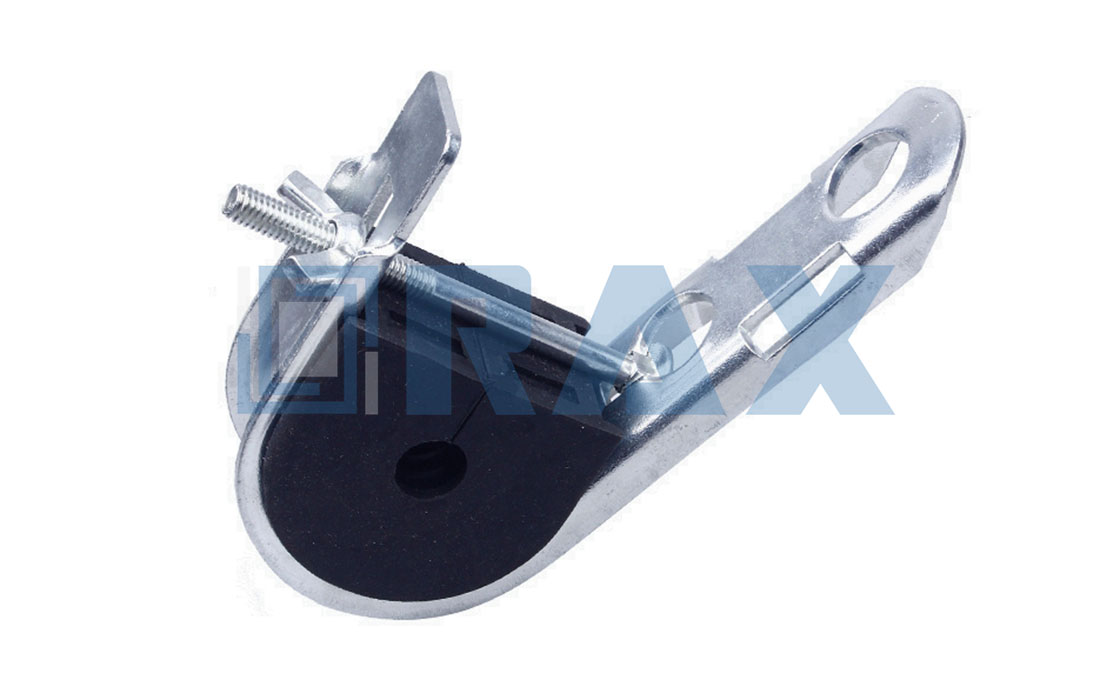

The assembly includes adjustable weights and frame, structural reinforcing rods applied over the conductor, an elastomer slit cushion for support, and retaining rods to secure the components. A rubber sleeve provides protection at the attachment point, while helical rods attach the pendulum and reduce compression forces on the conductor. Configurations accommodate single, twin, tri, quad, and hex-bundled conductors, with mass, weight quantity, and torsion arm length determined by span factors, conductor spacing, and diameter.

Rated for continuous operation at 250°C, pendulum weights typically range from 25 to 75 pounds. Placement accuracy within ±3 feet of designated locations ensures effectiveness. Installation via helicopter or bucket truck takes under three minutes per unit and can be performed on de-energized or live lines.

Design and placement require project-specific analysis based on span length, tension, tower dimensions, and icing levels. Field studies demonstrate that proper installation reduces galloping events, decreases motion amplitude, and extends transmission line longevity.

Detuning Pendulum Supplier for Enhanced Safety and Durability

Detuning Pendulum design and placement is project specific and requires analysis by RaxPower.

RaxPower’s Detuning Pendulum is engineered to minimize the amplitude of vertical conductor motion during a galloping event, reflecting our commitment to tailored design, protection, and safety in engineering solutions.

Established in 2003 in Hebei Province, China, with over 21 years of manufacturing expertise, we leverage advanced processes like hot forging and automation to ensure each component offers superior strength, accurate sizing, and durability. Our 17,000 square meter production facilities and skilled team of 170 employees, including 30 professional technicians and 10 engineers, uphold strict quality control from raw material selection to final testing.

The Detuning Pendulum features the following design details:

- Custom-configured for single, twin, tri, quad, and hex bundle setups to meet specific project requirements.

- Armor rods are applied to protect the outer aluminum strands from damage at the attachment location.

- Rubber sleeve provides an added layer of protection to the armor rods where the Detuning Pendulum is placed.

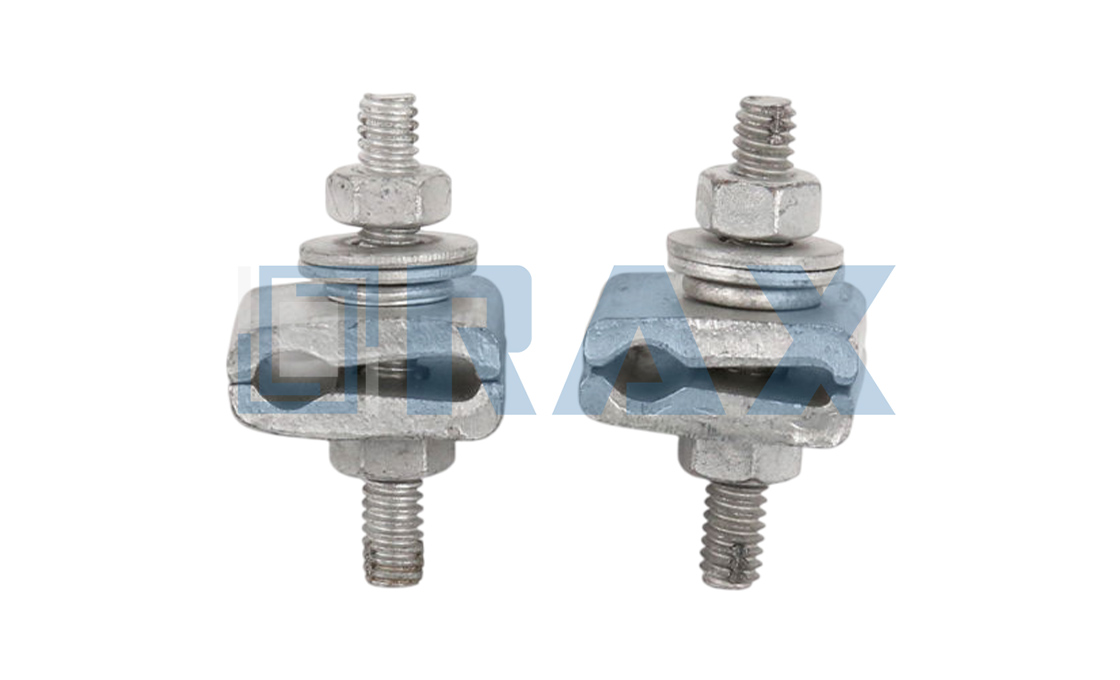

- Helical rods are used to attach the pendulum to the conductor, reducing strain on the underlying armor rods.

- Designed to match conductor spacing and diameter for a precise fit.

- 250°C Thermal Rating (Continuous)

- Weight varies between 25 lbs and 75 lbs depending on configuration.

The Detuning Pendulum can be applied to de-energized or live lines, with installation via helicopter or bucket methods for versatility.

All products undergo rigorous load testing and gauge tests according to international standards, ensuring 100% quality and reliability. Project-specific analysis by RaxPower is essential to deliver optimized, safe, and effective solutions tailored to your needs.

| Parameter | Specification |

|---|---|

| Thermal Rating | 250°C continuous operation |

| Pendulum Weight Range | 25 to 75 pounds |

| Placement Accuracy | ±3 feet from designated location |

| Installation Methods | Helicopter or bucket truck on de-energized or live lines |

| Installation Time | Under 3 minutes per unit |

| Supported Conductor Configurations | Single, twin, tri, quad, and hex bundle |

| Key Components | Pendulum assembly with adjustable weights and frame, structural reinforcing rods, elastomer slit cushion, retaining rods, rubber sleeve, helical rods |

| Operation Principle | Weighted arm opposes rotational force to change torsional frequency, preventing synchronization with vertical frequency and suppressing galloping |

| Design Basis | Project-specific, based on span length, tension, tower dimensions, and icing levels |

| Benefits | Suppresses galloping, reduces conductor clashing, increases cable longevity |

Frequently Asked Questions (FAQS)

What is a Detuning Pendulum and how does it work?

A Detuning Pendulum is a motion control device that minimizes vertical conductor motion during galloping events on power transmission lines. Its weighted arm opposes rotational force on the conductor and changes its torsional frequency, preventing synchronization with vertical frequency. This suppresses galloping, reduces conductor clashing, and increases cable longevity.

What components are included in a Detuning Pendulum assembly?

The assembly includes the pendulum with weights and frame, structural reinforcing rods, an elastomer cushion for support, retaining rods to secure it to the conductor, and a protective rubber sleeve for the outer aluminum strands.

What are the technical specifications and ratings?

Detuning Pendulums are rated for 250°C continuous operation and weigh between 25 to 75 pounds (11 to 34 kg) depending on the application. They are available in single, twin, tri, quad, and hex bundle conductor configurations, with designs tailored to match conductor spacing and diameter.

How are Detuning Pendulums installed?

Installation can be performed on de-energized or live lines using helicopter or bucket truck methods. Experienced linemen typically complete installation in less than three minutes per pendulum, with placement accuracy within ±3 feet of the specified location.

How does RaxPower customize solutions for specific projects?

RaxPower provides project-specific design and analysis, considering span, tension, tower dimensions, and icing levels. The pendulum weight and configuration are customized based on these factors to optimize performance while addressing cost efficiency and utility grid reliability requirements.

Get A Quick Quotation Today