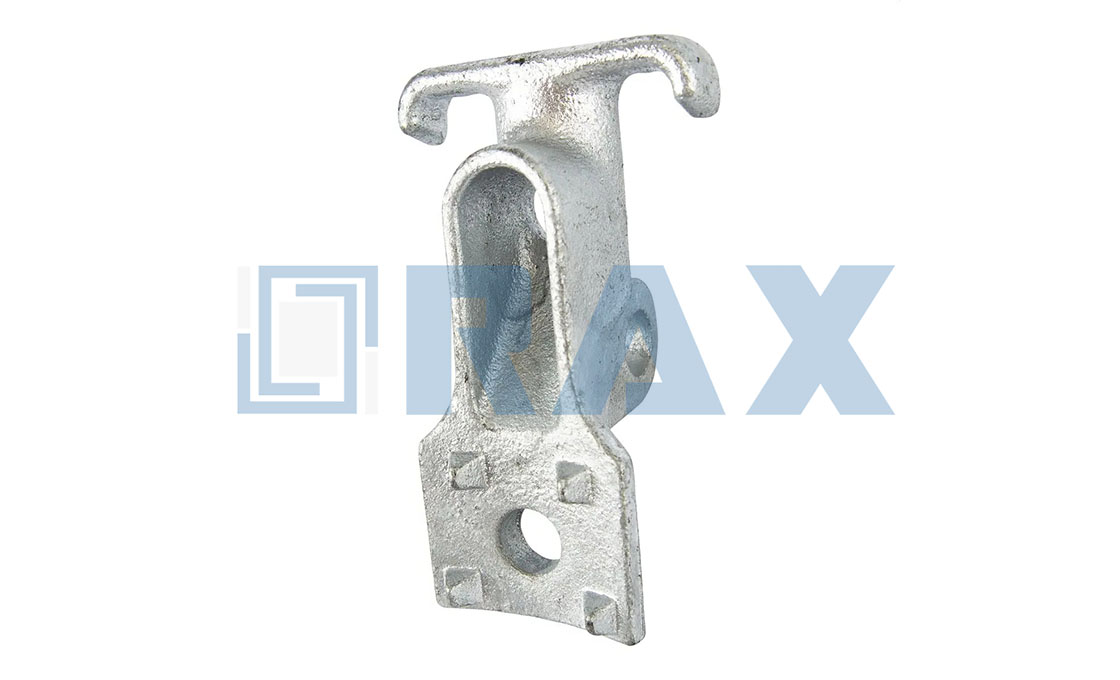

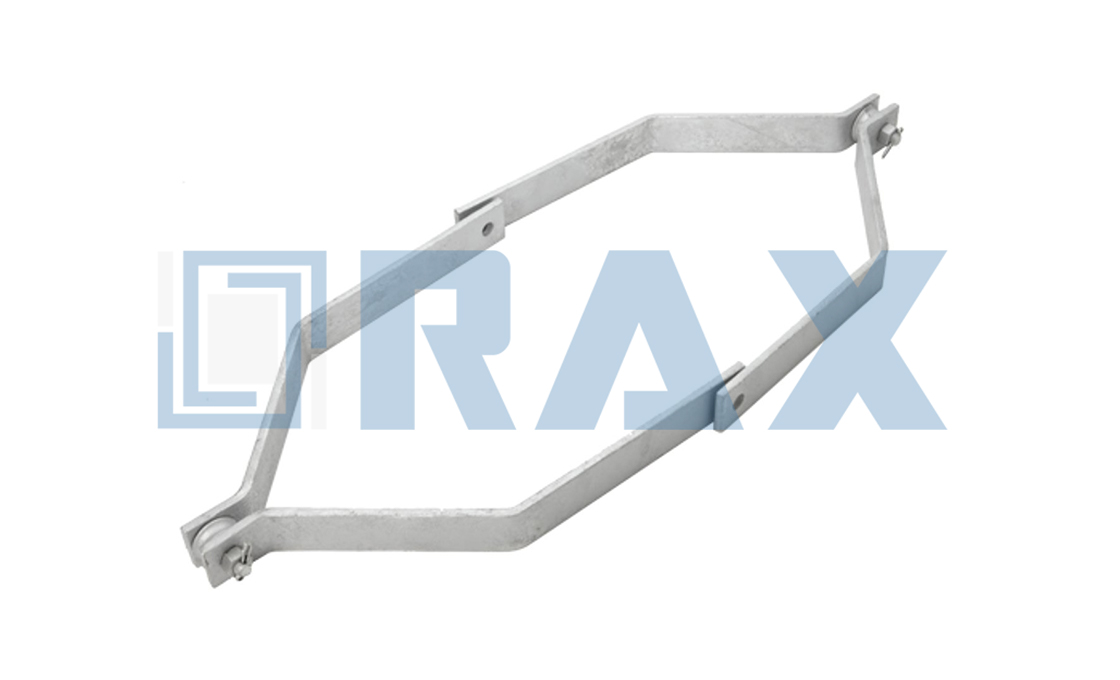

The Sidewalk Guy Clamp End secures guy wires in utility pole installations where traditional guying methods are impractical due to space constraints. Constructed from cast iron or ductile iron with a hot dip galvanized finish, this end fitting provides corrosion resistance and extended service life in outdoor environments. It works with standard pipe and is commonly utilized in urban settings where spatial limitations prevent conventional guying equipment.

These fittings are employed near sidewalks and buildings where insufficient space exists for standard guying configurations and maintaining head clearance is essential. The component ensures installations do not obstruct pedestrian or vehicular pathways in constrained areas.

The fitting accommodates standard pipe sizes, typically ranging from 2 inches to 2-1/2 inches in diameter. It is available in configurations with single, double, or triple clamps to secure the strand and may attach to pole plates using bolts and lag screws. The hot dip galvanized coating ensures consistent performance across various installation environments.

Installation requires additional components, such as a separate guy clamp (for example, the J931 model), which must be ordered individually. The assembly may involve specific bolts and lag screws, and in some cases, the fitting replaces standard clamp bolts to complete the guying system.

Reliable Sidewalk Guy Clamp End Supplier

RaxPower is a leading manufacturer of Pole Line Hardware and Fastener in China, with over 21 years of specialized experience in manufacturing and exporting. Our deep expertise in pole line hardware ensures that the Sidewalk Guy Clamp End is engineered for reliable performance in confined spaces near sidewalks and buildings, where standard guying is not feasible. We focus on delivering cost-effective, high-quality solutions through our own production facilities and stringent processes.

Our focus areas include:

- Pole Line Hardware

- Overhead Line Fittings

- Distribution Line Hardware

- Transmission Line Hardware

Our key advantages are:

- 21 years of manufacturing and export experience, guaranteeing dependable products like the Sidewalk Guy Clamp End

- Own production and galvanizing factory in Hebei, enabling direct control over quality and pricing

- Strict quality control from raw material selection to multi-stage testing, including hot-dip galvanizing per ISO 1461 with mean coating over 85 microns for corrosion resistance

- Products have passed SGS tests and authoritative institute evaluations, ensuring compliance and durability

- OEM and ODM services, with free samples and no MOQ for flexible ordering

Contact us for additional options, configurations, and expert support tailored to your needs.

| Clamp Configuration | Pipe Size (in) | Material | Finish | Wire Diameter Range (in) | Weight per 100 pieces (lbs) | Required Accessories |

|---|---|---|---|---|---|---|

| Single Clamp | 2 – 2-1/2 | Cast Iron or Ductile Iron | Hot Dip Galvanized | 1/4″ to 9/16″ | 400 | J931 Guy Clamp |

| Double Clamp | 2 – 2-1/2 | Cast Iron or Ductile Iron | Hot Dip Galvanized | 5/16″ to 9/16″ | 500 | J931 Guy Clamp |

| Triple Clamp | 2 – 2-1/2 | Cast Iron or Ductile Iron | Hot Dip Galvanized | – | – | J931 Guy Clamp |

Frequently Asked Questions (FAQS)

What are the key features and applications of the Sidewalk Guy Clamp End?

The Sidewalk Guy Clamp End is made from cast iron or ductile iron with hot-dip galvanized finish for corrosion resistance. It is designed for use with standard pipe (2″ or 2-1/2″ sizes) in constrained spaces near sidewalks and buildings where there is insufficient space for standard guying and where head clearance must be maintained. Available in single, double, or triple clamp configurations depending on the model, with certain models requiring a J931 guy clamp (ordered separately).

How is product quality verified for critical applications?

We implement a strict quality control system from raw material to finished products. After production, all goods are tested to meet required standards, utilizing processes like hot-dip galvanizing for durability and corrosion resistance.

Do you accommodate custom manufacturing requests?

Yes, we accept OEM and ODM services. Please supply the drawing, photo, or sample for custom specifications, and we will manufacture accordingly to meet your project requirements.

What is your policy on order quantities and sample availability?

There is no minimum order quantity (MOQ), and we deal with any quantity of your order. We also provide free samples upon request to ensure product suitability before larger purchases.

What are your standard lead times and payment conditions?

Delivery typically occurs within 10-15 days after receiving your payment or deposit. For orders under $1000, full payment in advance is required; for orders over $1000, a 30% T/T deposit with the balance before shipment is standard.

Get A Quick Quotation Today