Glass suspension insulators provide electrical insulation and mechanical support for conductors in overhead power transmission and distribution systems. They isolate and fix wires to transmission towers and substations in high voltage applications, ensuring safe electricity flow.

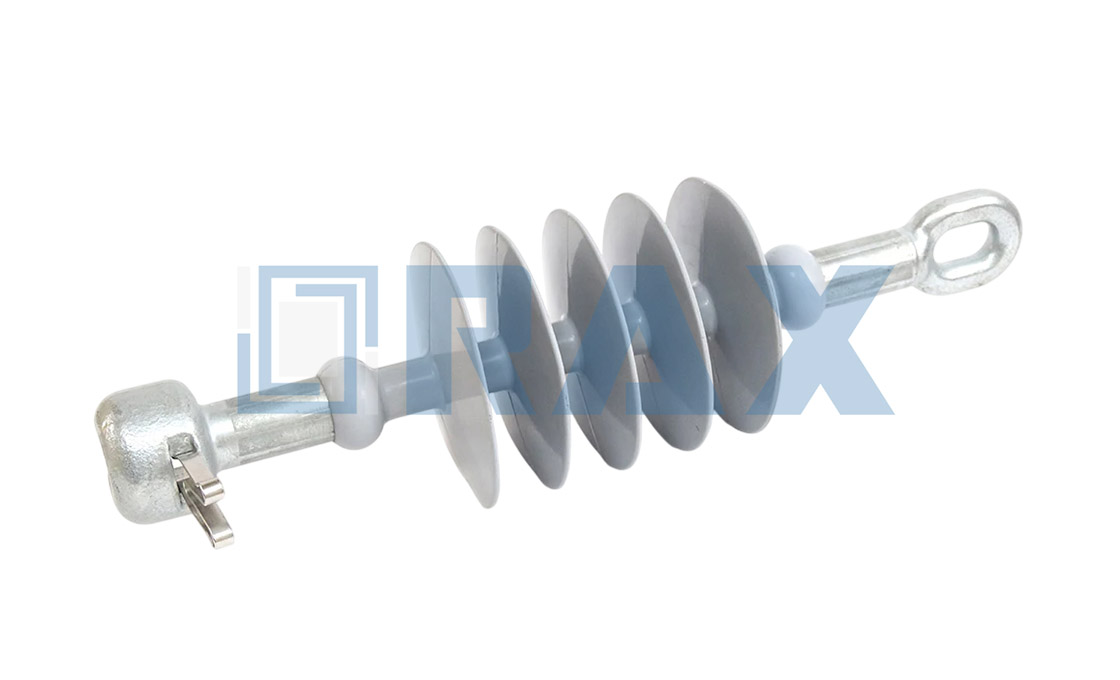

Each unit combines a toughened glass disc with metal fittings—a cap and pin made from galvanized steel or ductile iron—secured by cement bonding. The glass disc features sheds and ribs that enhance surface leakage paths. Available profiles include standard configurations with low-height ribs and fog-type designs with extended, widely-spaced under-ribs to prevent arc bridging in polluted conditions. Hydrophobic coatings may be applied to repel water and reduce contamination.

The toughened glass construction enables visual failure detection, as damage causes the glass to shatter, allowing easy identification without specialized testing. Mechanical strength varies across models, with minimum failing loads from 40 kN to 550 kN. Electrical properties include dry lightning impulse withstand voltages up to 140 kV, wet power-frequency withstand voltages of 40-50 kV, and creepage distances from 185 mm to 620 mm. The self-cleaning design facilitates natural cleaning by rain and wind, reducing maintenance needs.

Dimensions range from 178 mm to 380 mm in nominal diameter, 110 mm to 240 mm in height, and 2.1 kg to 21.5 kg in weight, ensuring compatibility with different system requirements and structural loads across various environmental conditions.

Expert Wholesaler of Premium Glass Suspension Insulators

RaxPower, established in 2003, has over two decades of experience as a leading manufacturer of pole line hardware, specializing in insulation products for transmission lines. Our Glass Suspension Insulator leverages this extensive expertise, ensuring high-quality and high-performance with a zero defect guarantee.

With 17,000 square meters of production workshops and a team of over 170 employees, including 30 professional technicians, we utilize advanced manufacturing processes like hot forging and automated machines to produce toughened glass insulators. Rigorous testing procedures, including load tests and SGS certifications, validate mechanical, electrical, and thermal reliability for demanding environments such as coastal and industrial zones.

The insulator’s design features visual fault detection and hot-dip galvanizing with a mean coating thickness over 85 microns for corrosion resistance. Ideal for high-voltage applications, it offers easy maintenance and consistent performance. For a free quotation and fast response to inquiries, contact RaxPower today.

| Parameter | Value |

|---|---|

| Mechanical Failing Load | 40 – 550 kN |

| Proof Load | 20 – 275 kN |

| Diameter | 178 – 380 mm |

| Height | 110 – 240 mm |

| Creepage Distance | 185 – 620 mm |

| Weight | 2.1 – 21.5 kg |

| Dry Lightning Impulse Withstand Voltage | 140 kV |

| Wet Power-frequency Withstand Voltage | 40 – 50 kV |

| Puncture Voltage | >130 kV |

| Coupling Size | 16 mm |

| Material | Toughened glass disc with galvanized steel or ductile iron fittings |

| Operating Temperature Range | -60°C to +50°C |

| System Voltage | >1000 V AC |

| System Frequency | Up to 100 Hz |

Frequently Asked Questions (FAQS)

What advantages do glass suspension insulators offer over other types?

RaxPower glass suspension insulators provide high mechanical strength, superior dielectric properties, visual failure detection through glass shattering, slow aging, and corrosion resistance. They eliminate the need for periodic live testing and offer lightweight, easy installation with long-term reliability.

What are the main components of a glass suspension insulator?

RaxPower glass suspension insulators consist of an insulating glass disc, metal fittings such as a cap and pin at each end, and cement bonding material. The glass disc features sheds and ribs for enhanced leakage distance and water drainage.

What electrical and mechanical specifications are available?

RaxPower glass suspension insulators provide dielectric strength with dry flashover voltages up to 80 kV, wet flashover voltages up to 50 kV, lightning impulse withstand voltages up to 110 kV, and creepage distances from 185 mm to 620 mm. Mechanical failing loads range from 40 kN to 550 kN across models like U70B, U120B, and U160B.

How are glass suspension insulators installed and maintained?

Installation involves assembling multiple units into vertical strings, with the count determined by system voltage. They connect using standard couplings like ball-and-socket or tongue-and-clevis designs. Maintenance is minimal due to self-cleaning properties, requiring only periodic visual inspections for damage or contamination.

What environmental conditions and profile options are available?

RaxPower insulators suit coastal, industrial, and polluted environments. We offer standard, fog, and open-type profiles with extended ribs to prevent arc bridging and reduce contamination. Hydrophobic coatings enhance performance in wet or salty conditions, and customization options include specific creepage distances and mechanical ratings for specialized applications like telecommunications or railway electrification.

How do you ensure reliability and standards compliance?

Our insulators undergo rigorous testing including mechanical failing load tests, electrical withstand voltage tests, and thermal shock testing. We ensure compliance with international standards like ANSI C29.2 and IEC 60305, with visual failure detection features enhancing grid safety and reducing maintenance needs.

What is your production capacity for large-scale projects?

With over 20 years of experience, we operate 17,000 square meter facilities with automated processes for consistent quality. Our capacity handles bulk orders seamlessly, ensuring on-time delivery through advanced technologies like hot forging and semi-automatic molds that maintain accuracy and meet project timelines.

What quality control and client support do you provide?

We implement strict quality control from raw material selection to final inspection, including multi-stage testing like load tests, gauge tests, and chemical analysis adhering to ISO standards. We provide SGS certifications, competitive wholesale pricing, a broad product catalog, samples, OEM services, and flexible payment terms for distributors and OEM clients.

Get A Quick Quotation Today