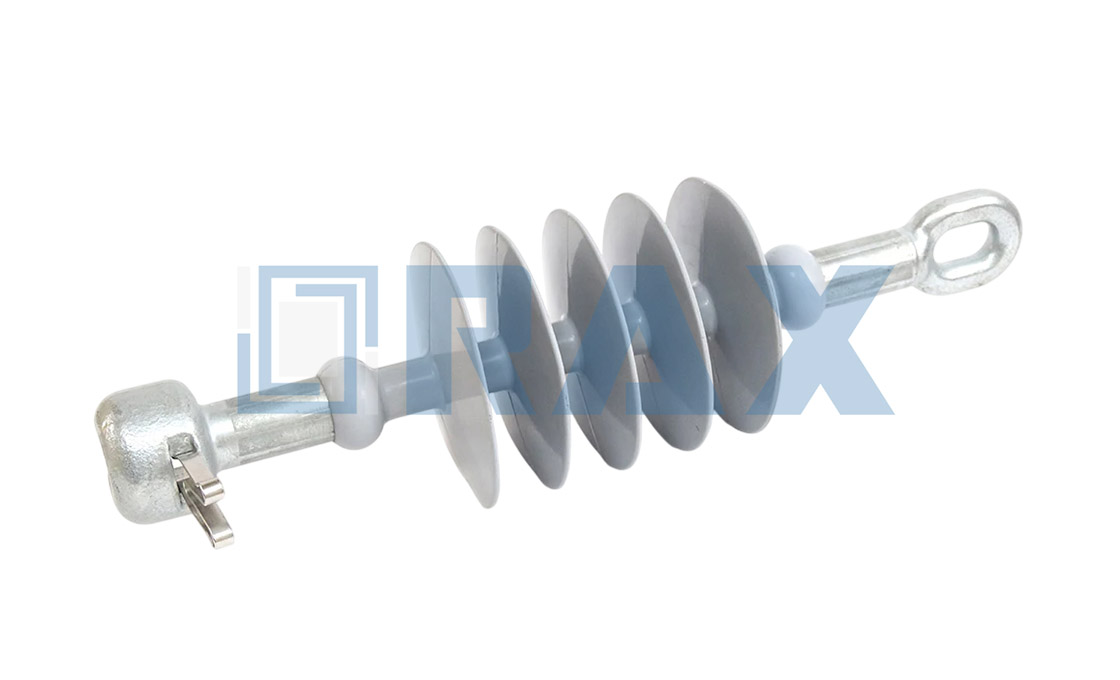

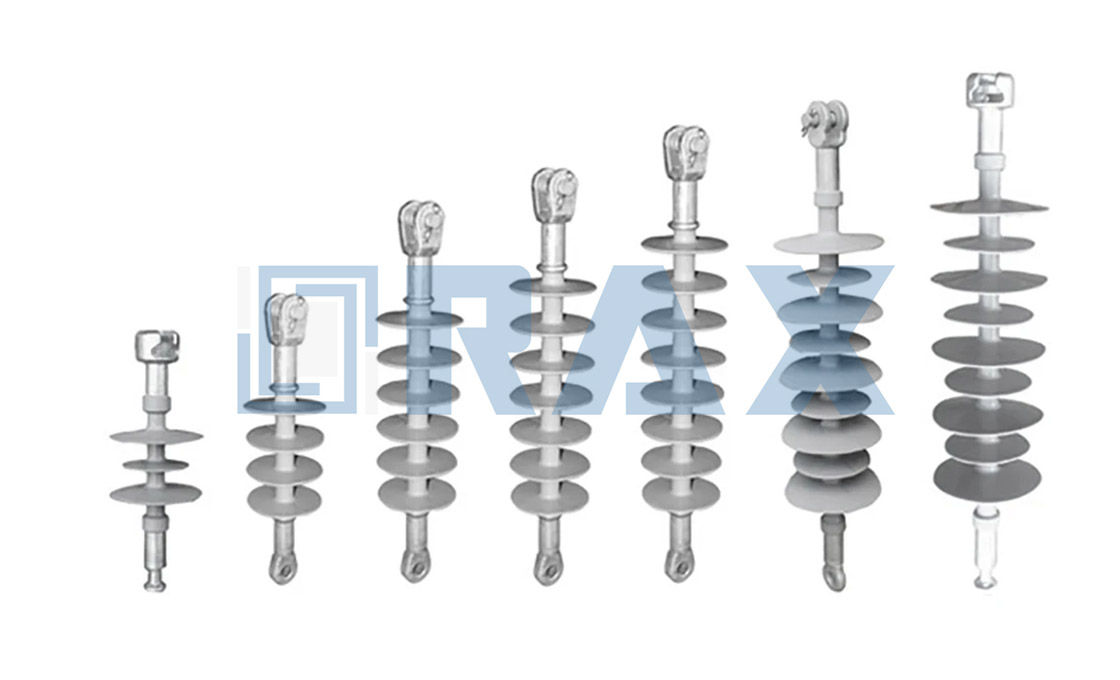

Deadend insulators provide insulation and mechanical support at terminal points where conductors end or change direction in overhead distribution systems operating at or below 69 kV. Manufactured to polymer insulator standards, they serve line terminations, angles, and tangents in suspension or deadend configurations with both bare and covered conductors.

The construction combines a silicone rubber housing with a fiberglass core through injection molding and bonding. This composition delivers hydrophobic properties for wet condition performance, plus resistance to ultraviolet (UV) radiation, moisture, and chemical corrosion. The lightweight design—ranging from 1.8 to 3.5 pounds—and corrosion-resistant fiberglass core facilitate handling and installation while maintaining structural integrity under mechanical stress.

Mechanical specifications include loads up to 70 kN with routine test loads of 35 kN and maximum torsional loads of 50 Nm. Electrical ratings span 15 kV to 69 kV, with dry flashover voltages reaching 200 kV, wet flashover voltages up to 166 kV, and critical impulse flashover ratings for transient protection. Optimized dry arc distances and leakage distances ensure reliable insulation performance.

These insulators reduce maintenance requirements, minimize outages from vandalism and flashovers, and lower leakage currents for improved energy efficiency. Compliant with American National Standards Institute (ANSI) C29.13 and certified by Canadian Standards Association (CSA) and Rural Utilities Service (RUS), they meet established safety and performance standards for diverse urban, rural, and industrial applications.

Deadend Insulator Wholesaler with Decades of Expertise

RaxPower is committed to providing customers with a full range of power transmission solutions. Established in 2003 and based in Hebei Province, China, we have over 21 years of manufacturing and exporting experience as a specialist in pole line hardware, including high-performance Deadend Insulators that deliver robust insulation and mechanical support for terminal points in electrical systems.

With over 170 employees, 17,000 square meters of production workshops, and 5,000 square meters of warehouses, we ensure reliable capacity and timely delivery.

Our strict quality control, advanced processes like hot forging for superior strength and accurate sizing, automation for uniformity, and multi-stage testing—including load and gauge tests—guarantee that every Deadend Insulator offers high dielectric strength, durability, corrosion resistance, and compliance with international standards, maximizing customer satisfaction.

We look forward to a successful business relationship with you!

| Parameter | Specification |

|---|---|

| Rated Voltage | 15 – 69 kV |

| Section Length | 13.0 – 24.6 in (330 – 626 mm) |

| Dry Arc Distance | 7.4 – 18.1 in (188 – 460 mm) |

| Leakage Distance | 15.8 – 52.8 in (401 – 1340 mm) |

| Dry Flashover Voltage | 90 – 200 kV |

| Wet Flashover Voltage | 65 – 166 kV |

| Critical Impulse Flashover Positive | 140 – 323 kV |

| Critical Impulse Flashover Negative | 145 – 380 kV |

| Weight | 1.8 – 3.5 lb (0.8 – 1.6 kg) |

| Specified Mechanical Load (SML) | 70 kN |

| Routine Test Load (RTL) | 35 kN |

| Maximum Torsional Load | 50 Nm |

| Material | Silicone Rubber |

| Standards | ANSI C29.13, CSA Certified, RUS Accepted |

Frequently Asked Questions

What is a deadend insulator used for?

Deadend insulators are used on overhead lines operating at or below 69 kV to support line conductors in suspension or deadend modes such as line terminations, angles, and tangents. They are also utilized in substations and industrial applications to support and insulate electrical equipment like transformers and switches.

What are the advantages of using deadend insulators?

Advantages include increased safety, improved reliability, enhanced performance, reduced costs, and lightweight design for easier handling and installation. They offer resistance to environmental factors like UV radiation, moisture, and pollution with consistent performance over their service life. They minimize interruptions from vandalism, pole fires, and flashovers while eliminating or reducing maintenance such as washing and trouble calls. They also enhance power quality with lower leakage currents and reduced radio interference.

What materials are used in the construction of deadend insulators?

Deadend insulators are constructed with a silicone rubber housing and a fiberglass core. The core rod may be made of epoxy resin, and end fittings are typically manufactured from steel or other corrosion-resistant metals, ensuring durability and longevity.

What are the key electrical ratings for deadend insulators?

Key electrical ratings include voltage ratings from 15 kV to 69 kV, dry arc distance, leakage distance, and flashover voltages such as 60 Hz dry flashover (e.g., 135 kV for 28 kV models), 60 Hz wet flashover (e.g., 100 kV), and critical impulse flashover (e.g., 225 kV positive).

What mechanical strength specifications do deadend insulators have?

Mechanical strength specifications include specified mechanical load (SML) values such as 15.7 klb (70 kN) and routine test load (RTL) values such as 7.9 klb (35 kN). They are designed to withstand high mechanical loads and tension from conductors, with maximum torsional loads up to 37 ft/lbs.

What certifications and standards do your deadend insulators meet?

Our deadend insulators are certified to ANSI standards, CSA certified, and RUS accepted, meeting or exceeding industry requirements such as ANSI C29.13 and ANSI Class standards for reliability and safety in power transmission and distribution systems.

How do you maintain consistent quality and performance?

We implement strict quality control throughout production, including testing of raw materials and finished products for chemical composition, physical, and electrical properties. All goods are tested according to related standards, with ex-factory test reports provided to guarantee consistent performance and durability.

Do you offer customization for specific voltage ratings or fitting requirements?

Yes, we accept OEM services and can customize deadend insulators for specific voltage levels, fitting types (such as clevis-tongue or ball-socket), and application needs to meet unique project demands.

Can you handle large project orders and ensure on-time delivery?

We maintain stock of standard models and can efficiently produce large orders, with customizable packaging options to suit land, air, or sea transportation, ensuring timely delivery for project timelines.

Get A Quick Quotation Today