Anchor rods are threaded fasteners embedded in concrete foundations to provide stability and support for structural steel columns, light poles, traffic signals, highway signs, and industrial equipment. They resist tension and shear forces, securing superstructures to foundations in construction and manufacturing applications.

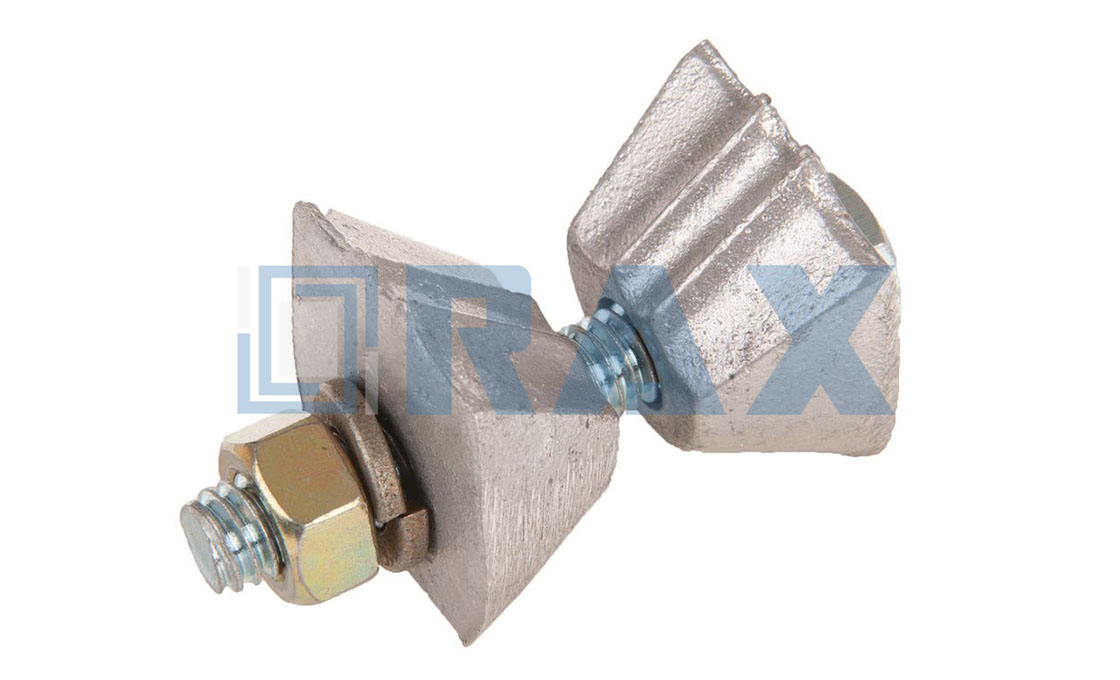

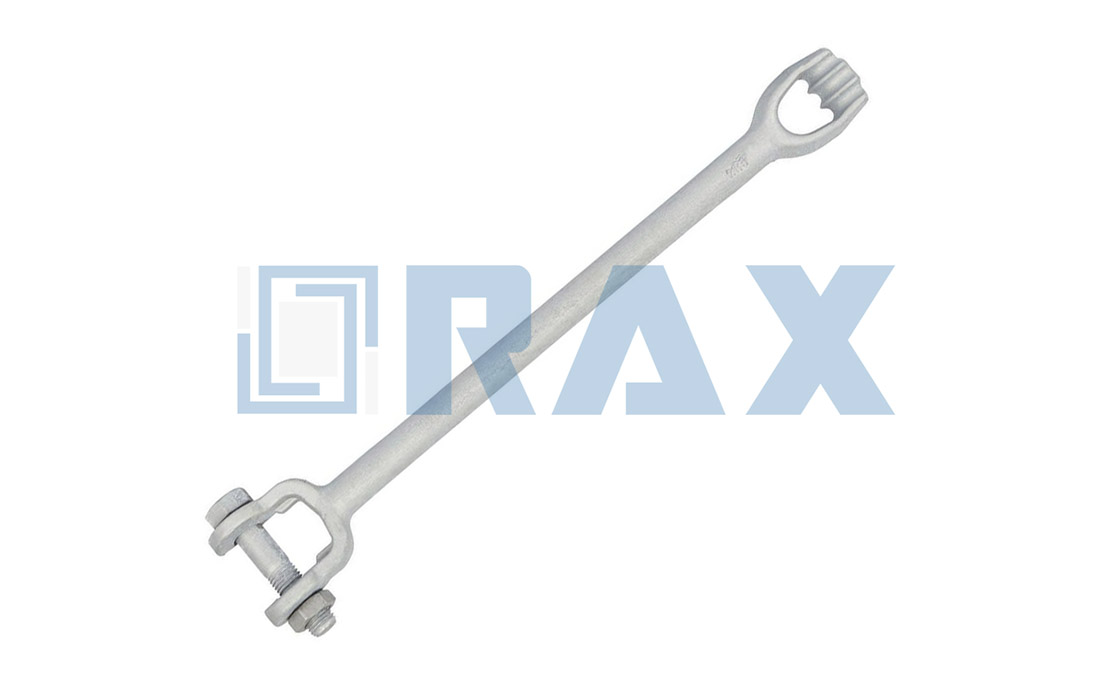

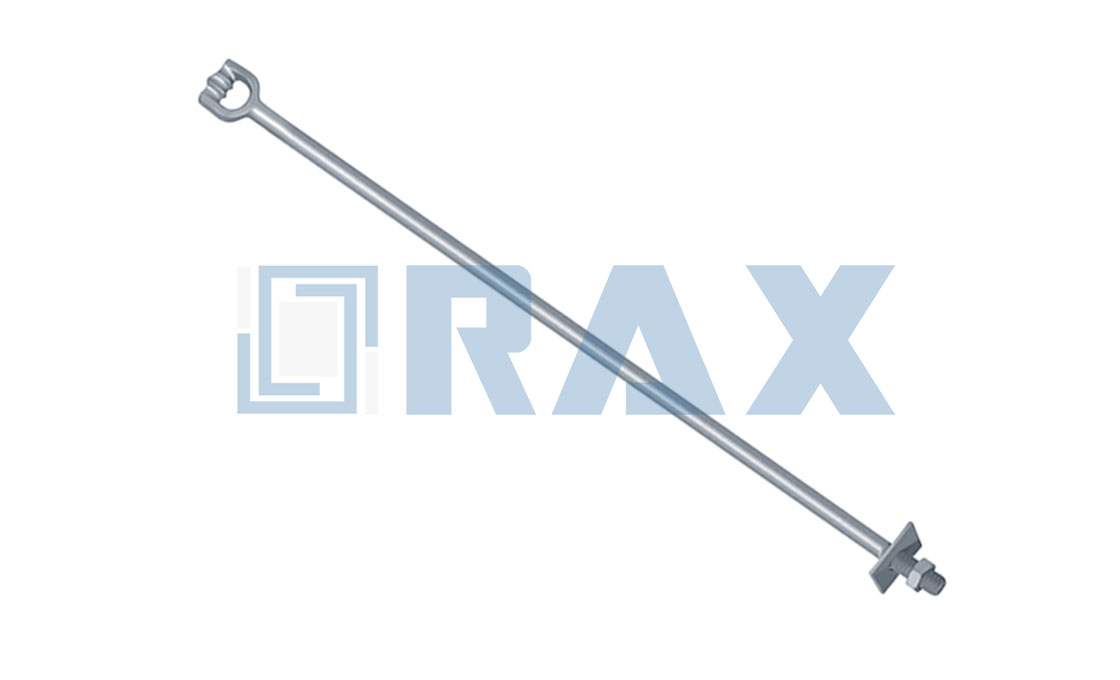

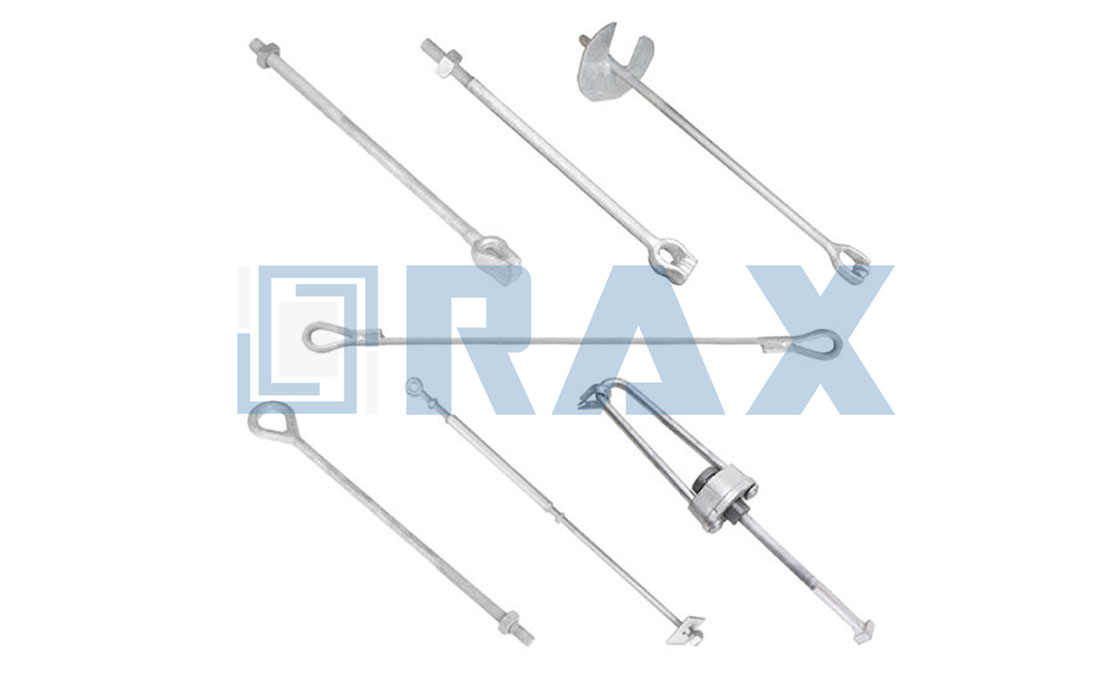

Available in cast-in-place and post-installed configurations, anchor rods include straight rods, L-shaped or J-shaped bent bolts, and fully threaded rods. Customization options include forged heads, swedged ends, or epoxy bonding. The embedded end features nuts, plates, forged heads, or epoxy to prevent pullout, while the projecting threaded end uses nuts and washers to secure attached structures.

Specifications follow standards like ASTM F1554 (grades 36, 55, and 105, with yield strengths of 36 ksi, 55 ksi, and 105 ksi), ASTM A449, A354, A193, and A320. Materials range from carbon steel to stainless steel alloys (304 and 316), with diameters from 1/2 inch to 6 inches. Finishes include hot-dip galvanizing or zinc plating for corrosion resistance.

Manufacturing involves cutting steel round bar, threading, and operations like forging, swedging, or welding. Accessories include nuts, washers, anchor plates, coupling nuts, and sleeves. For post-installed systems, adhesive capsules or injectable hybrid epoxy mortars bond rods in pre-drilled holes, enabling retrofitting in existing concrete structures.

Premier Anchor Rod Manufacturer

RaxPower has manufactured and distributed the highest-quality anchor rods and pole line hardware since 2003, and in that time, we have become the industry experts. As China’s leading manufacturer, we specialize in R&D, production, and sales, operating from 17,000 square meters of production workshops and 5,000 square meters of warehouses in Hebei, China, with over 170 employees dedicated to excellence.

Our anchor rods are designed to anchor structural supports to concrete foundations, used in bridges, highways, industrial equipment, and power transmission projects. We offer:

- Straight, bent, and headed anchor rods

- Diameters from 1/2″ to 4″

- ASTM-compliant specifications

- Hot-dip galvanized finishes for enhanced durability

The reliability of our anchor rods is backed by advanced manufacturing processes, including hot forging for superior strength and precise sizing, and in-house galvanizing with mean coating thickness over 85 microns. Our multi-stage quality control—featuring load testing and gauge checks per international standards—ensures every product meets rigorous demands.

Serving diverse industries such as marine construction, steel fabrication, and energy, we prioritize quick turnaround times and efficient delivery to keep projects on schedule and within budget. With 21 years of experience, our philosophy is rooted in consistency, accountability, and attention to detail.

Email sales@lightningboltandsupply.com for all of your anchor rod needs.

| Parameter | Specification |

|---|---|

| Product Type | Anchor Rod (also known as Anchor Bolt, Foundation Bolt) |

| Common Types | Straight, Bent (L-shaped, J-shaped), Fully Threaded Rod |

| Configurations | Cast-in-place, Post-installed (e.g., with epoxy or expansion systems) |

| Standards | ASTM F1554 (Grade 36, 55, 105), ASTM A449, ASTM A354, ASTM A193 (Grade B7, B8, B8M), ASTM A320 (Grade L7, B8, B8M), F593 (Alloy Group 1, 2) |

| Materials | Carbon Steel, Stainless Steel (304, 316), Alloy Steel |

| Diameter Range | 1/2 inch to 6 inches |

| Length Range | Custom, commonly up to 40 feet |

| Thread Options | Fully threaded, partially threaded with specified top and bottom thread lengths |

| Finish | Plain Steel, Hot-Dip Galvanized, Zinc-Plated |

| Anchoring Elements | Nut, Washer, Plate, Forged Head, Epoxy Bonding, Swedged End |

| Applications | Structural Steel Columns, Light Poles, Traffic Signals, Highway Sign Structures, Industrial Equipment, Bridges, Stadiums |

Frequently Asked Questions(FAQS)

What are anchor rods and what are they used for?

Anchor rods are threaded fasteners embedded in concrete foundations to support structures such as light poles, traffic signal poles, structural steel columns, highway sign structures, and industrial equipment. They resist tension and shear forces, providing stability and strength across construction, highway projects, marine applications, power generation, and infrastructure like wind farms and solar structures.

What types and configurations of anchor rods are available?

Anchor rods come in various configurations including straight rods, bent anchor bolts (L-shaped or J-bolts), headed bolts, all thread rods, and swedged rods. They are available in multiple diameters, lengths, and thread types, with options for carbon steel, alloy steel, or stainless steel (304 or 316). Custom solutions can include anchor plates, sleeves, or special bends tailored to engineering specifications.

What ASTM specifications are common for anchor rods?

Common ASTM specifications include F1554 (with grades 36, 55, and 105 indicating minimum yield strength), A307, A449, A354, A193, A320, and F593 for stainless steel. F1554 is specifically designed for anchor bolts, while others like A193 are used for high-temperature or corrosive environments.

How are anchor rods installed in concrete?

Anchor rods can be cast-in-place during concrete pouring using positioning templates, or post-installed in existing concrete. Post-installation involves drilling holes, cleaning, and inserting the rod with epoxy, adhesive capsules, or injectable mortars for a secure bond.

What corrosion protection finishes are available?

Finishes include plain steel, hot-dip galvanized, zinc-plated, and other coatings to enhance corrosion resistance for outdoor, marine, or harsh environments, ensuring durability and longevity.

Do your anchor rods meet international standards for reliability?

Yes, we manufacture anchor rods to various ASTM specifications, including F1554 Grades 36, 55, and 105, ensuring extreme product reliability and full compliance for critical applications such as utility grid maintenance where certified hardware is essential.

How do you maintain consistent quality while offering competitive pricing?

Our in-house manufacturing capabilities, including hot forging, hot-dip galvanizing, and automated machinery, enable cost control while ensuring uniform quality and accurate sizing. Strict quality control measures—from raw material selection through multi-stage testing—guarantee perfectly consistent quality, delivering significant cost savings ideal for OEM clients, distributors, and importers.

How do you ensure on-time delivery for large orders?

We prioritize on-time delivery through efficient in-house production processes and automated systems, allowing for quick turnaround and reliable scheduling. Our commitment ensures bulk orders for projects like grid expansions or infrastructure builds are completed and delivered as scheduled, minimizing downtime.

Get A Quick Quotation Today