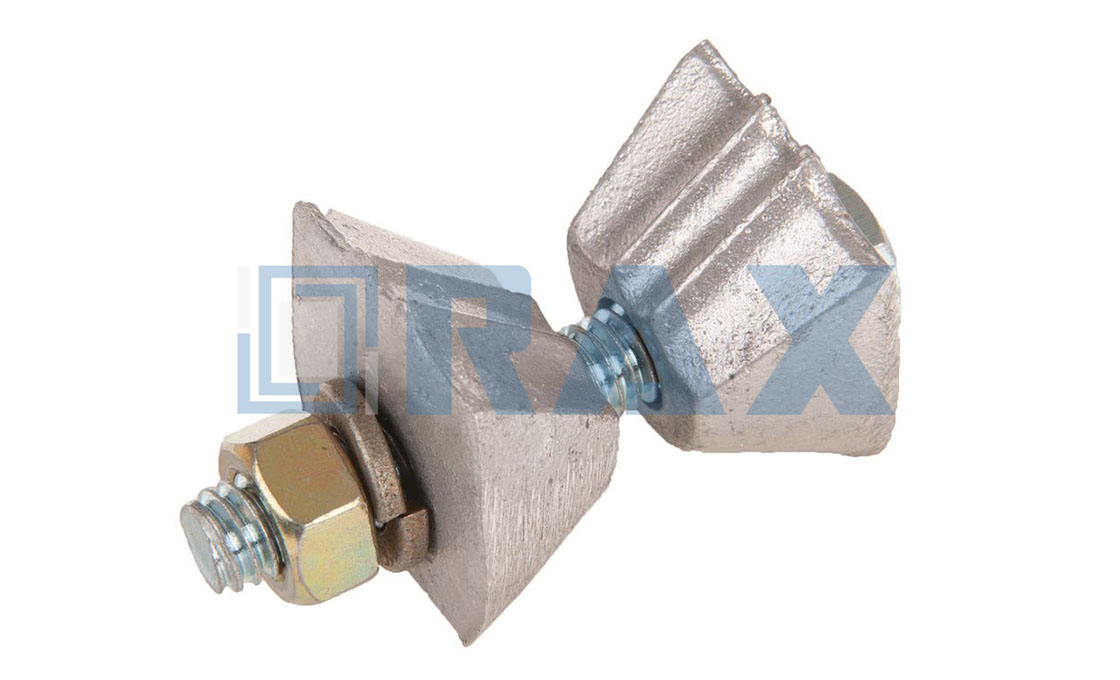

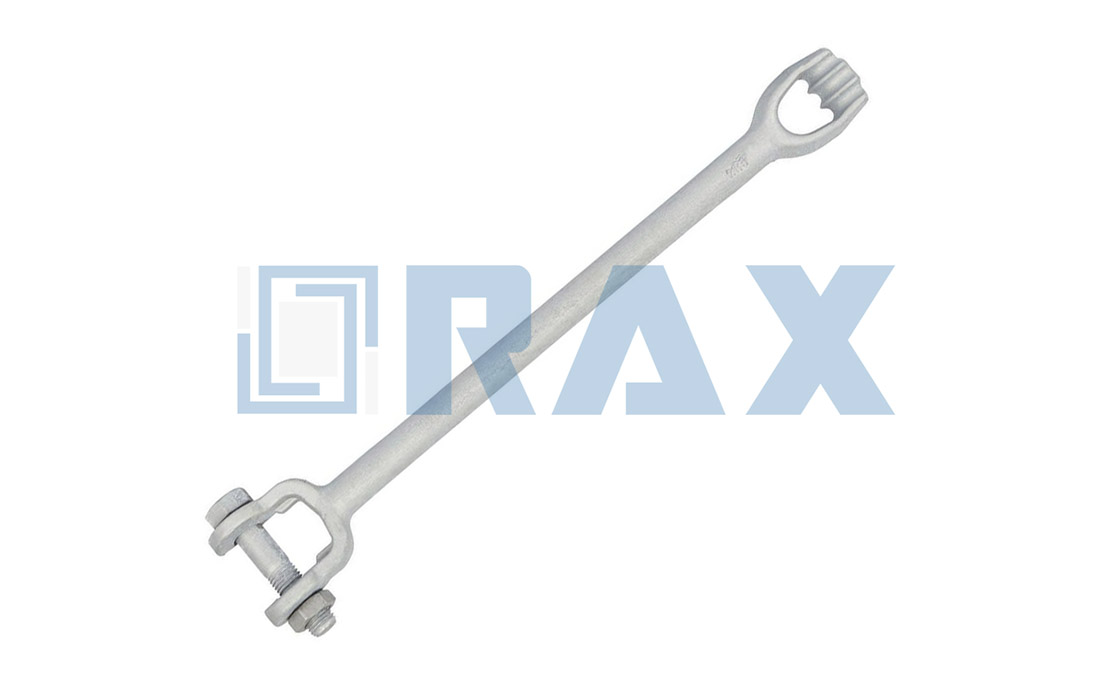

Helical pile caps connect helical piles to superstructures, transferring loads in both compression and tension. These steel components distribute structural forces from buildings or frameworks directly to embedded helical piles.

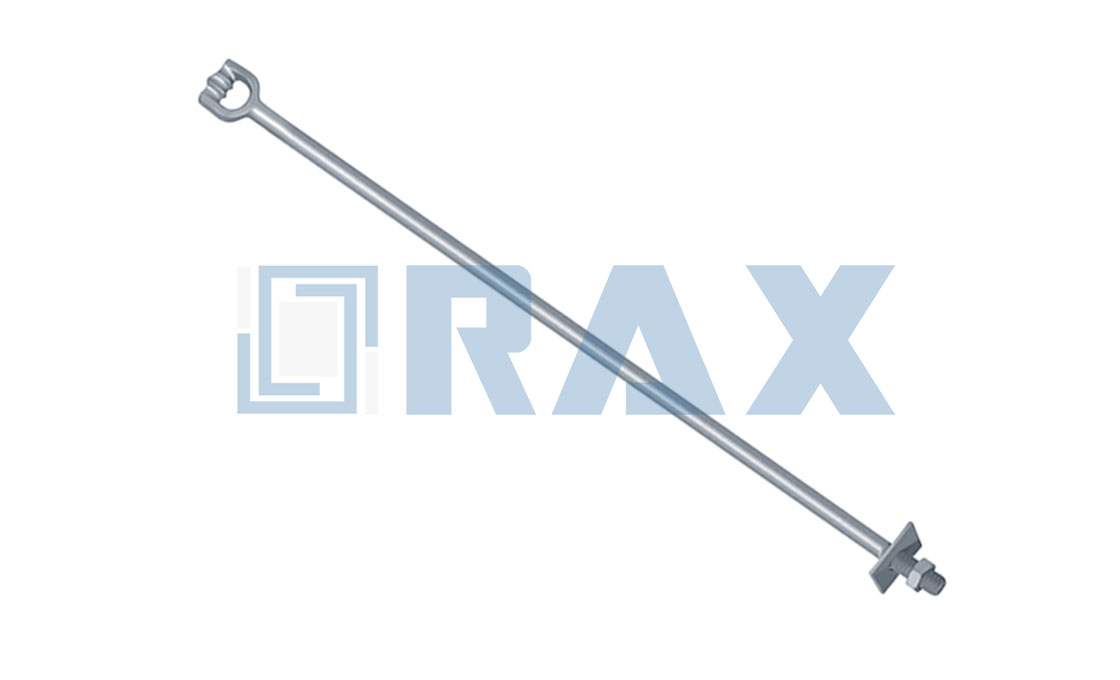

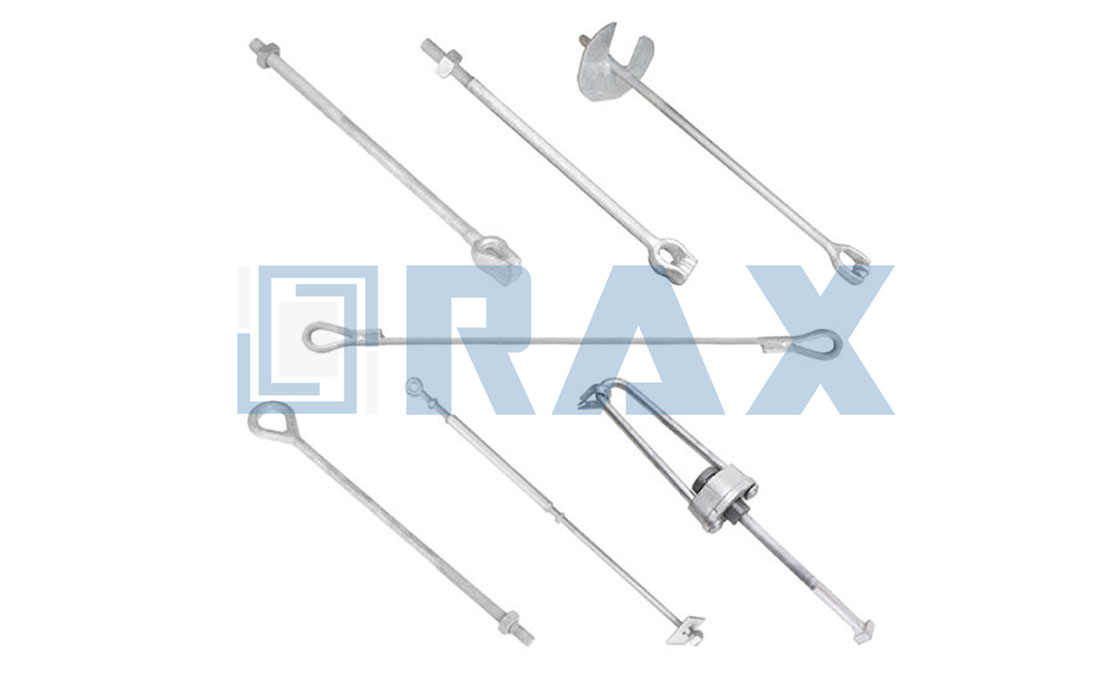

Helical pile caps are fabricated from hot-dip galvanized steel plates, L-plates, or U-brackets with thread rods for adjustability. Electro-galvanized and plain steel alternatives are available based on project requirements. Standard sizes range from 6″×6″ to 10″×10″ with typical plate thicknesses of 1/2″, though custom dimensions accommodate varying load requirements. Models support allowable compression loads up to 16 tons and tension loads up to 0.5 tons, with ultimate capacities reaching 32 tons and 1 ton respectively. Compatible with helical pile shafts from 1.5″ to 2″ inner diameter, thread rods are available in standard 1″×6″ dimensions or custom lengths.

Product types include adjustable caps for elevation fine-tuning during installation, fixed caps for direct bearing connections, and specialized brackets for new construction, repair, and marine applications. Installation requires cutting the helical pile shaft to proper elevation, placing the cap over the shaft, and securing with bolts using 50–60 foot-pounds of torque. This process ensures direct bearing and alignment with minimal soil disturbance.

Helical pile caps are manufactured under ISO 9001 quality standards and compatible with round or square shaft systems. Customization through original equipment manufacturer (OEM) services adapts the caps to specific helical pile dimensions and diverse foundation applications including underpinning and marine structures.

Helical Pile Cap Wholesaler with Lifetime Warranty

As a full-service pile manufacturing company, RaxPower leverages over 21 years of expertise to produce high-capacity steel helical piles that are affordable, manufactured rapidly, and delivered directly to your jobsite.

Our helical pile caps benefit from advanced hot forging technology, ensuring superior strength and precise sizing for reliable performance in diverse soil conditions.

With 17,000 square meters of production facilities and stringent quality control—including multi-stage testing, ISO-compliant galvanization, and load verification—we guarantee durability and efficiency.

Ideal for foundation repair, new construction, and applications like solar arrays or decks in residential, commercial, and industrial projects, our products are ISO 9001:2015 certified and backed by a lifetime warranty.

Contact us today for immediate answers and to explore becoming a distributor or installer.

| Parameter | Value |

|---|---|

| Product Type | Adjustable Cap, Fixed Cap, Specialized Brackets |

| Standard Plate Sizes | 6″ x 6″, 8″ x 8″, 10″ x 10″ |

| Plate Thickness | 1/2″ |

| Weight (for 6″ x 6″ x 1/2″ cap) | 40 lbs |

| Dimensions (varies by size) | e.g., 20″ x 20″ x 20″ |

| Allowable Compression Load | 16 tons |

| Allowable Tension Load | 0.5 tons |

| Ultimate Compression Load | 32 tons |

| Ultimate Tension Load | 1 ton |

| Pipe Size Compatibility (Inner Diameter) | 1.5″ to 2″ |

| Thread Rod Size | 1″ x 6″ or customized |

| Materials | Steel (plates, L-plates, U-brackets, thread rods) |

| Finishes | Hot-dip galvanized, Electro-galvanized, Non-galvanized (plain steel) |

| Installation Torque | 50–60 ft-lbs |

| OEM Service | Available (customization of materials and specifications) |

| Quality Standards | ISO 9001 |

Frequently Asked Questions

What is a helical pile cap and what is its purpose?

A helical pile cap is designed to transfer the load of the structure to the helical pile bracket. It is used in new construction and repair projects to attach piers to framing, providing a stable connection point.

What standard sizes, specifications, and materials are available?

Common plate sizes include 6

How do helical pile caps connect to helical piles and what is the installation process?

They feature a collar tube with bolt holes for direct bearing connection to the pile shaft, compatible with pipe sizes like 2″ I.D. After installing the helical pile to the correct depth, torque, and capacity, cut the shaft square at the proper elevation. Place the pile cap over the shaft and secure with a bolt, tightening to a minimum torque of 50 ft-lbs and not exceeding 60 ft-lbs.

What are the load capacities of helical pile caps?

Allowable compression capacities can reach up to 16 tons, and allowable tension up to 0.5 tons, with ultimate compression up to 32 tons and ultimate tension up to 1 ton.

Do you offer OEM services for custom helical pile caps?

Yes, we provide comprehensive OEM services, allowing customization of helical pile caps in various sizes, materials, plate thicknesses, pipe dimensions, and surface finishes. Our engineering team collaborates closely with clients to develop cost-effective solutions tailored to your project needs without compromising on quality or consistency.

Are your helical pile caps certified for use in critical infrastructure like utility grids?

RaxPower's helical pile caps are manufactured under stringent quality control systems and undergo rigorous testing, including load tests and galvanization thickness checks per ISO 1461 standards, with mean coating thickness exceeding 85 microns. They are designed to comply with international standards such as IEC 120 for gauge tests, ensuring reliability and suitability for critical applications in power transmission and other infrastructure projects.

How do you ensure corrosion resistance and long-term durability in demanding environments?

Our helical pile caps feature advanced hot-dip galvanizing with controlled liquid temperatures to achieve smooth, bright surfaces without defects. This zinc coating provides excellent corrosion protection, and we conduct thorough quality checks to ensure durability in harsh conditions, including exposure to moisture, vibration, and temperature fluctuations, making them ideal for telecommunications, railway, and renewable energy applications.

Can you accommodate large-volume orders and guarantee on-time delivery?

With 17,000 square meters of production workshops and 5,000 square meters of warehousing, RaxPower maintains stock of common helical pile cap sizes for quick shipments. Our automated manufacturing processes and efficient logistics enable us to handle bulk orders reliably, ensuring on-time delivery to keep your project timelines on track.

Get A Quick Quotation Today