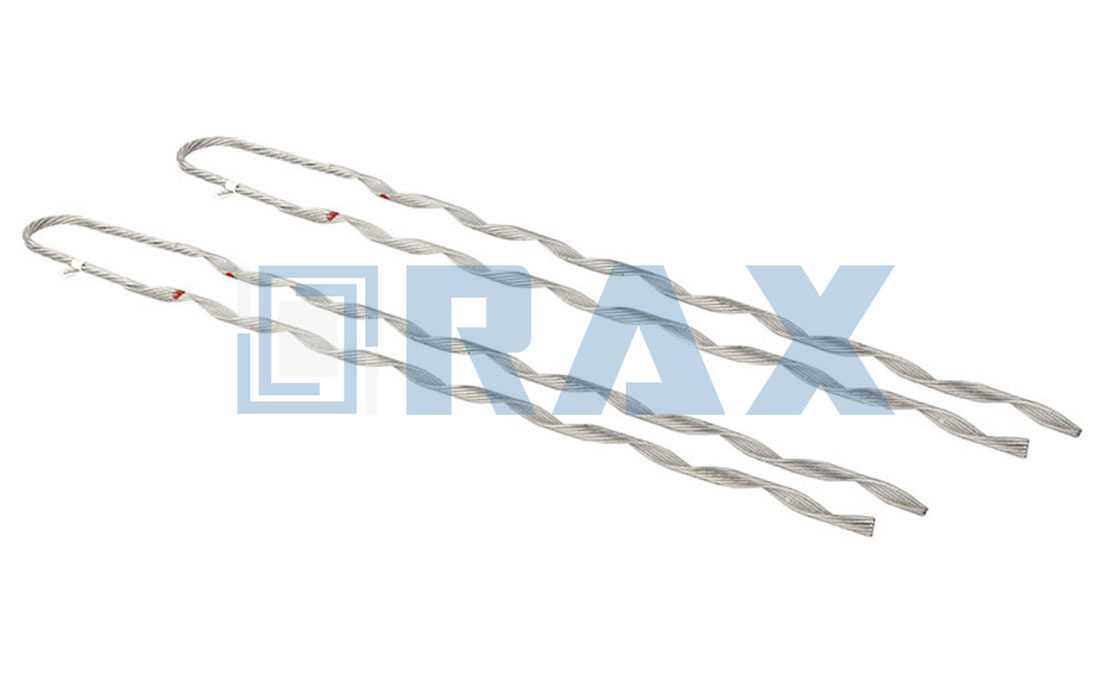

The Dead End Grip is a helical formed wire termination device that securely anchors guy wires to poles, towers, and structures in utility and telecommunications infrastructure. It provides reliable strain relief through a mechanical holding mechanism in overhead and down guy wire applications, including transmission lines, antenna supports, and communication structures.

Manufactured from galvanized steel, aluminum-coated steel, or aluminum-clad steel wire—often complying with ASTM A 855—the material selection typically matches the strand to ensure compatibility. The helical design develops 100% of the strand’s published rated breaking strength while providing uniform grip that prevents conductor distortion. This design eliminates bolts, nuts, and washers, allowing easy installation by hand in most applications.

Available specifications accommodate diameters from approximately 0.182 to over 1.2 inches, with applied lengths varying by size (25 inches for 1/4 inch strands, 35 inches for 3/8 inch models). Color coding enables size identification, and grips are available in left or right lay constructions to match strand lay direction. The device is compatible with Aluminum Conductor Steel Reinforced (ACSR), all-aluminum, aluminum alloy, Aluminum Conductor Alloy Reinforced (AWAC), and compacted ACSR conductors, including plastic jacketed variants.

Distribution Grip Dead End

Helical termination designed for bare aluminum-based conductors on distribution lines, providing required holding strength without cutting or splicing. Grips conductor uniformly to prevent distortion, eliminating bolts and washers for secure primary and secondary installations.

Dead End Grip Supplier for Secure Terminations

As China’s leading manufacturer of pole line hardware with over two decades of experience, RaxPower is dedicated to designing and manufacturing reliable utility structures that meet stringent requirements. Our Dead End Grip is recommended as a replacement for bare looped dead ends due to its strong loops and high holding power on ACSR cables and other conductors, ensuring secure terminations for transmission, distribution, and telecommunication applications.

The Dead End Grip functions by wrapping helically formed legs around the conductor or stay wire, forming a closed circle that prevents slipping and provides a firm connection to anchor rods or insulators. Installation is straightforward and often tool-free, with color-coded sizes and left or right lay directions for easy matching to the strand.

Manufactured from high-quality materials such as aluminum-clad steel wire, our grips are produced using advanced processes like hot forging for greater strength and accurate sizing. We employ strict quality control, including raw material selection, multi-stage testing, and automated production to ensure uniformity and durability. Our hot-dip galvanizing technology adheres to ISO standards, providing corrosion-resistant, smooth surfaces without defects.

As employee-owners, we take customer service seriously, with a dedicated team of over 170 professionals committed to timely delivery and support. For bulk pricing or to speak with our sales consultants, contact us today.

Frequently Asked Questions

What is a dead end grip and how does it work?

A dead end grip is a helical formed wire device used for terminating and gripping strands in utility applications. It works by wrapping its helical legs around the cable, forming a closed circle that provides a strong grip to prevent slipping. This allows secure connection to anchor rods or insulators on poles and towers, providing stability in transmission, antenna, communications, and other guyed structures.

What materials are dead end grips made from?

Dead end grips are manufactured from the same material as the strand they are applied to, typically including aluminum wire, galvanized steel wire, or aluminum clad steel wire. This ensures compatibility and optimal performance.

What is the strength rating of dead end grips?

Dead end grips are rated to hold 100% of the strand's published rated breaking strength, designed to develop the full rated strength of the strand for reliable performance in critical applications like grid maintenance and expansion.

What sizes are available and how do I identify them?

Dead end grips are available in various sizes to match strand diameters, with common sizes including 1/8, 3/8, and 5/16. Color codes are used for easy identification and proper sizing during installation.

How do you install a dead end grip?

Installation involves attaching a thimble clevis, aligning the two legs parallel to the cable using color codes for proper sizing, and wrapping the grip securely around the cable by hand without the need for tools in most cases.

What quality control measures ensure compliance with standards?

RaxPower implements strict quality control including load testing and gauge tests per IEC 120 standards, with products passing SGS tests and tests by authoritative research institutes. Our hot-dip galvanizing process follows ISO 1461, ensuring a mean coating thickness of over 85 microns for durability and compliance.

Can you accommodate custom specifications and large volume orders?

Yes, RaxPower can customize dead end grips according to your specific designs and requirements, supporting all sizes and variations for specialized needs. We offer tailored bulk pricing and utilize our 5,000 square meters of warehouses in China with efficient logistics to ensure on-time delivery for large-scale projects.

Get A Quick Quotation Today