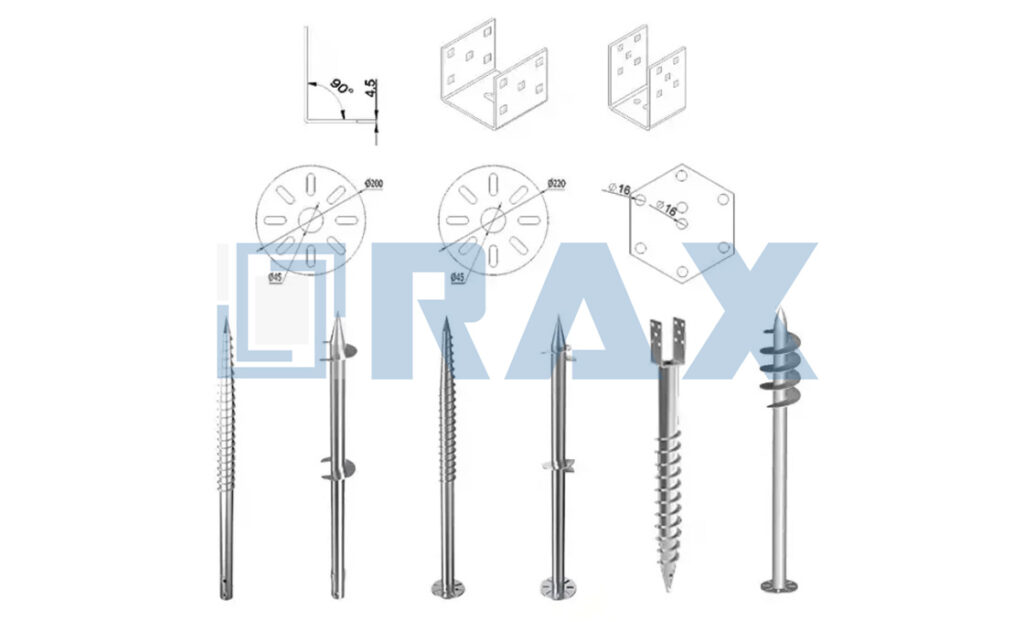

Solar panel foundations anchor photovoltaic arrays to the ground, providing stability against wind and snow loads. Helical pile foundations use galvanized steel or aluminum piles screwed into the ground with hydraulic equipment, reaching depths of 7 to 14 feet based on soil conditions and load requirements. Torque monitoring during installation ensures each pile meets capacity specifications without requiring excavation or concrete.

Helical piles install rapidly compared to concrete foundations, with no curing time needed and immediate panel loading capability. The process minimizes site disturbance through minimal vibration and zero excavation, allowing year-round installation even in challenging terrain or inclement weather. Piles are removable and reusable, supporting project reconfiguration or decommissioning with reduced environmental impact and lower costs from eliminated curing delays and reduced labor needs.

These foundations withstand wind speeds up to 60 meters per second and snow loads up to 1.4 kilonewtons per square meter. Galvanized or anodized coatings provide corrosion resistance and durability, with service lives exceeding 25 years. The design accommodates various soil types and mounting configurations across utility-scale farms, commercial installations, and residential projects on flat, sloped, or uneven terrain.

Solar Panel Foundation Manufacturer: 21 Years of Engineering Excellence

RaxPower provides a completely unique service in China for large-scale solar farm projects. Our mission is to promote clean energy by designing, engineering, and manufacturing innovative solar panel foundations that save customers time, energy, and money. With 21 years of experience, we optimize every step of the construction process to improve ROI.

Our integrated approach includes:

- Test piling and site assessment for cost-efficient foundation design.

- Optimized engineering by our in-house team of 30 technicians and 10 engineers.

- Manufacturing in 17,000 square meter facilities using hot forging technology for superior strength and hot-dip galvanizing for corrosion resistance.

- Installation that withstands wind speeds up to 60m/s and snow loads up to 1.4kN/m², ensuring durability.

Benefits include reduced project times, enhanced risk management, and significant cost savings. We address common challenges like soil variability and design errors through accurate testing and experienced solutions. Our team ensures quality from raw material to final product.

If you want to know more, please speak to one of our experts today, free of charge.

| Parameter | Value |

|---|---|

| Foundation Type | Helical Pile |

| Material | Galvanized Steel or Aluminum |

| Corrosion Protection | Galvanized or Anodized |

| Wind Load Capacity | Up to 60 m/s |

| Snow Load Capacity | Up to 1.4 kN/m² |

| Installation Depth | 7-14 ft |

| Piles per Panel | 1-6 |

| Terrain Compatibility | Flat, sloped, uneven terrain |

| Standards | AS/NZS 1170 and other international standards |

| Warranty | Service life >25 years, lifetime warranty on some systems |

Related Products

Frequently Asked Questions

What are the key advantages of using helical piles for solar panel foundations?

Helical piles offer minimal environmental impact, installation in days rather than weeks, no excavation or landscape disruption, and a removable, reusable system that is easier to relocate than concrete foundations.

How does the installation process compare to traditional concrete foundations?

Helical piles can be installed and immediately loaded within days, eliminating the concrete curing time required by traditional methods. Typical installation depth ranges from 7 to 14 feet depending on soil conditions, with 1 to 6 piles needed per array based on project specifications.

How adaptable are your foundation systems to different site conditions?

Our foundations install effectively in diverse terrains including rocky, sandy, or expansive soils. They require no additional footings and cause zero excavation, making them ideal for environmentally sensitive sites while supporting sustainable development goals.

How can your solutions help reduce overall project costs?

By eliminating concrete curing time and reducing installation labor, our foundations lower total expenses. Minimal site preparation, reusable components, and efficient bulk supply capabilities provide significant cost savings compared to traditional methods.

How do your systems ensure long-term reliability and industry compliance?

Our products undergo rigorous quality control including load testing and hot-dip galvanization to ISO standards. Automated manufacturing with multi-stage inspections guarantees durability and full compliance with industry regulations for grid maintenance and expansion.

What capabilities support large-scale projects with tight deadlines?

Extensive manufacturing capacity, automated processes, and drop-shipping capabilities enable timely delivery of bulk orders. We efficiently handle custom designs while maintaining quality standards to keep projects on schedule.

How much does installation cost for a solar panel project?

Costs vary by project specifications. Contact RaxPower for a customized quote based on your specific requirements.

Get A Quick Quotation Today